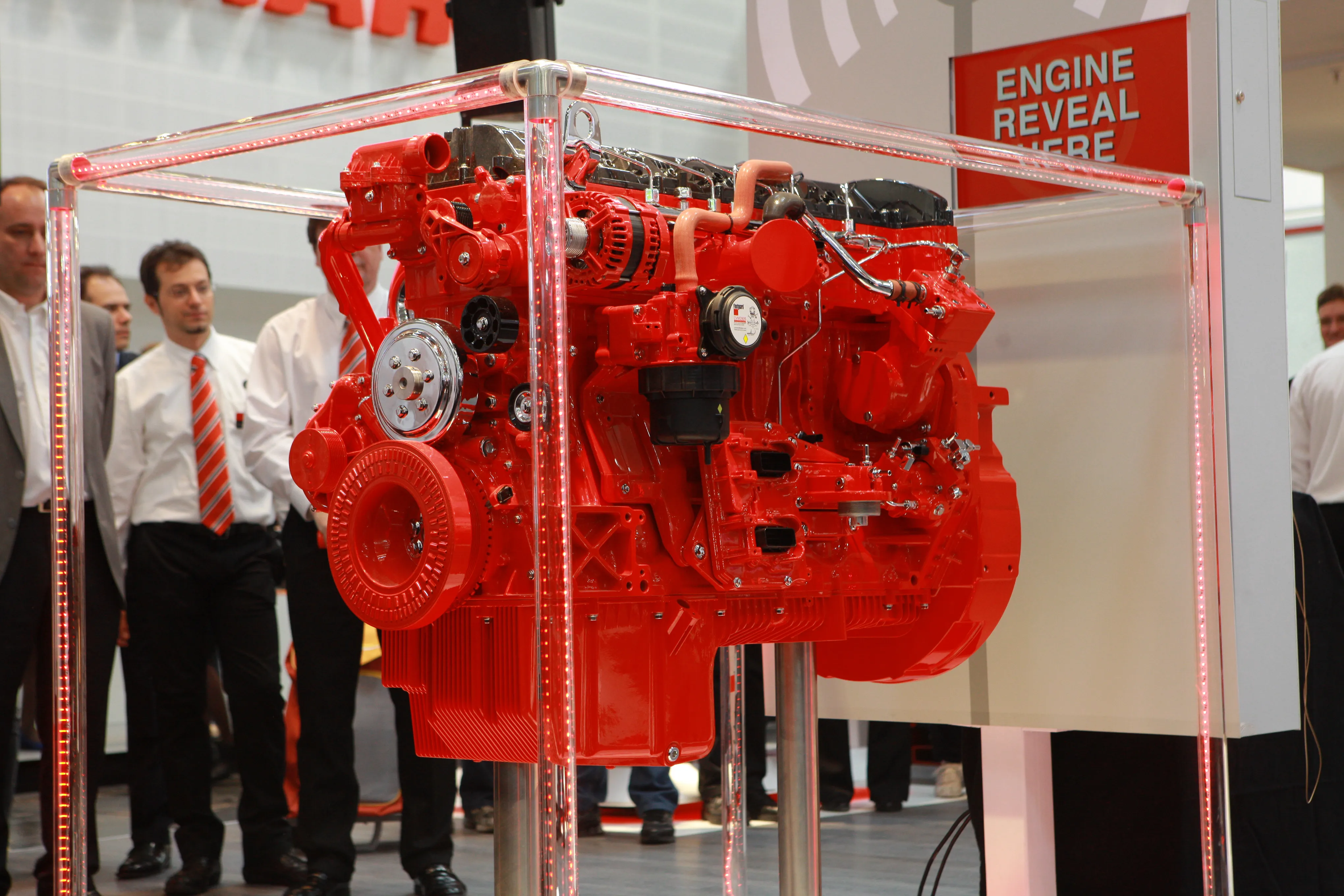

The 67kW Compact Hi-eSCR engines, designed and manufactured by Case’s partner company FPT -

One operational benefit of these changes is better load response, enabling the engine to react more quickly to sudden demands for increases in torque which happens often during the operation of a skid steer.

This high-performing engine has excellent torque output (383Nm at 2,500rpm) and is directly coupled to the hydraulic pumps. This means that all the power of the engine is transferred directly to the wheels.

New model numbers have been introduced. The radial lift SR270 and vertical lift SV340 skid steer loaders replace the previous top-of-the-range SR250 and SV300 models. The radial lift TR340 compact track loader replaces the TR320. The vertical lift TV380 track loader also achieves lower emissions, but because its operating capacity is unchanged it retains the same model name.

The rated operating capacity rises from 1135kg in the SR250 to 1,225kg in the new SR270; from 1,360kg in the SV300 to 1,545kg in the new SV340; and from 1,451kg in the TR320 to 1,542kg in the new TR340.

To support the increased performance, the vertical lift models come with a stronger lift arm, as well as reinforced H-link and upper chassis.

Another real-world advantage of these upgraded models is their outstanding bucket breakout force, which ranges from 38.6kN on the SR270 up to 42.4kN on SV340.