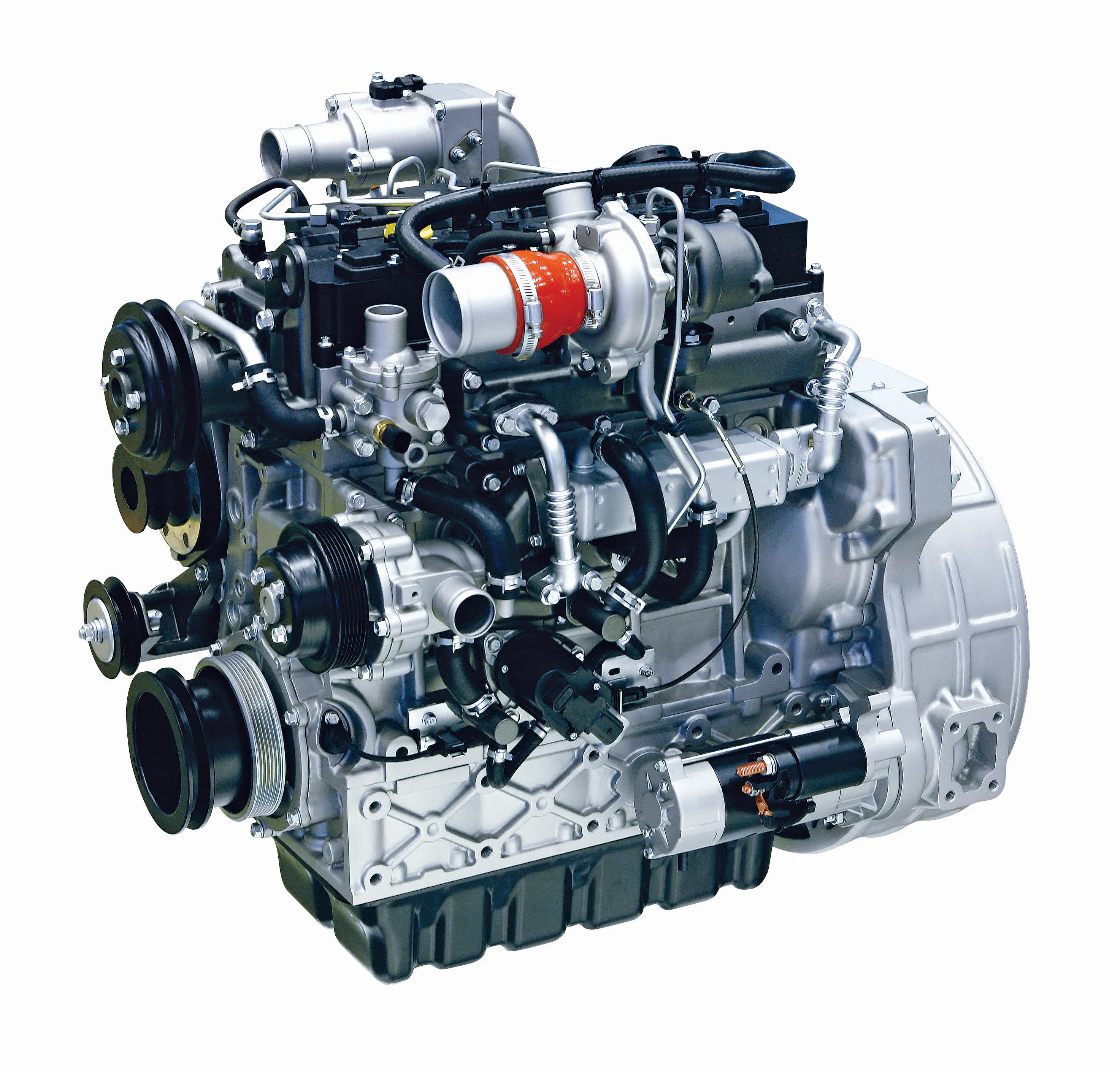

The company says the new TA9 and TA10 models offer users increased fuel efficiency without any exhaust after-treatment requirements.

“Launching this first-to-market range of Stage IIIB/ Tier 4 Final-compliant nine and ten tonne site dumpers is an exciting move for Terex Construction,” says Neal Nowick, general manager of Terex Construction’s Coventry facility in central England.

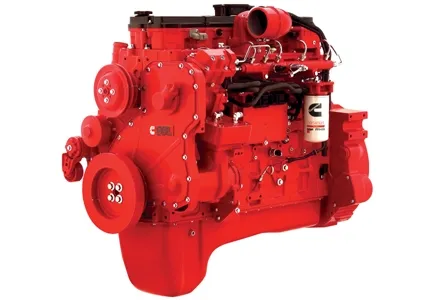

“Ensuring our site equipment meets the latest international regulations, in particular emissions control, is essential, which is why we made the decision to move away from our current engine solution and instead look towards the 55kW EcoMAX alternative.

“Each new TA9 and TA10 site dumper is fitted with the enhanced engine set-up, delivering a compliant on-site solution capable of meeting the highest international emissions regulations.”

The launch of Terex Construction’s Stage IIIB/Tier 4 Final-compliant range of 9tonne and 10tonne site dumpers completes the transition of the brand’s portfolio (TA6, TA6S, TA9 and TA10) of site dumpers to JCB as the new exclusive engine supplier.

Meanwhile,

Terex Construction says its new first-to-market dumpers feature an innovative Liquid Crystal Display (LCD) dashboard, complete with hour meter, coolant temperature gauge and fuel level readout. Early warning alerts help to prevent costly downtime and enhance operator safety. In addition, a user readout panel provides real-time machine information, while Engine Control Unit (ECU) technology manages performance data to improve reliability.

The company plans to maintain a price freeze on the TA9 and TA10 models throughout 2015.