SWARCO Traffic has specified and installed 10 of its prism signs, managed by its cloud-based Zephyr solution, along the UK’s M6 motorway in northern England.

The signs help to advise drivers of diversion routes and other traffic information and updates for Highways England along the M6 in county Cumbria.

Highways England, which is responsible for management and the maintenance of England’s trunk roads, needed to upgrade the route’s existing signs with a system that was more reliable and durable. It turned to infrastructure support services group Amey and SWARCO to provide the solution.

Chris Keatley, SWARCO’s traffic project manager, said the existing signs were in urgent need of upgrading. “They had to be taken down and repaired multiple times in the past few years. Every time they needed to re-direct traffic or communicate key messages and information for motorists, it required somebody to attend the site in person and perform the task manually, which requires significant resource, labour and cost,” he said.

Messages can be updated remotely at the touch of a button from a desktop or mobile and, importantly are equipped with a de-icing feature to avoid seizing up during winter.

“This scheme was the first phase of the diversion route improvements and over the next few years we hope to replace all the existing signs with SWARCO units,” said Paul Clark, Highways England’s project manager for the northern counties of Cumbria and North Lancashire.

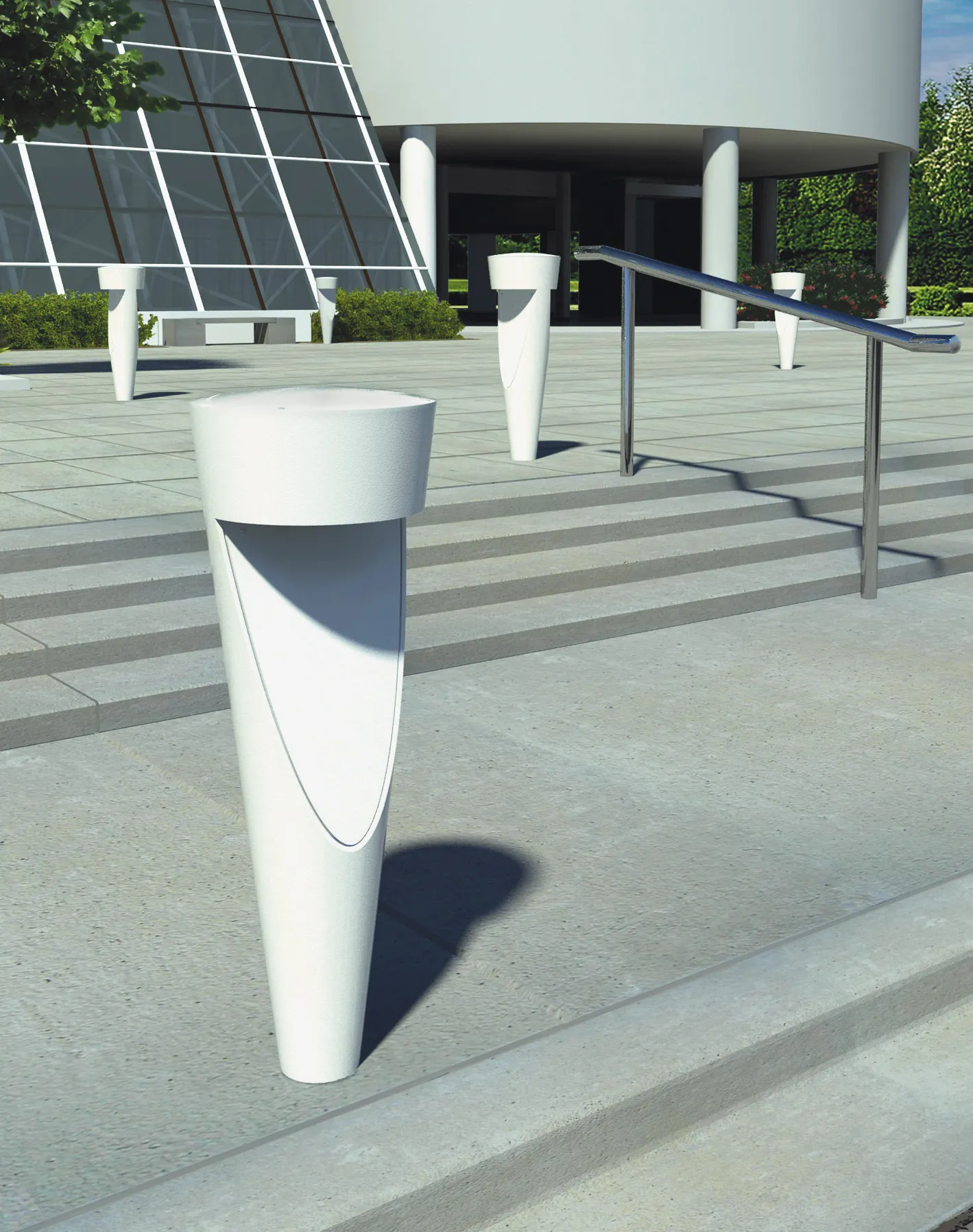

Prism signs use rotating planks of aluminium to display up to three messages, such as warning of diversion routes or road closures, semi-permanent pedestrian zones or where pre-set messages are needed to alternate.

The product range offers solutions with internally illuminated prisms of 100mm or 200mm sections. These are located within a closed enclosure behind a polycarbonate screen or open prisms and can be presented vertically or horizontally depending on the application. The corrosion-free aluminium sign enclosures are protected up to IP54 and can be co-ordinated to colour requirements.

Due to their extremely low power consumption, prism signs are suited for solar power supply. Energy is required almost only during message rotation.

SWARCO said that a special feature of the company’s prism signs is the sinusoidal drive which controls the message changes. It starts with a high momentum, increasing speed during the process and then slowing down at the end of the motion phase. This ensures exact prism alignment.

The drive then locks the prisms to protect them from external influences such as high winds. As well as optional temperature-controlled de-icing cycles the sinusoidal drive process considerably helps reduce mechanical wear and tear and maximises the sign’s life span.

The signs also feature a local override in the event of a power failure or for maintenance purposes.

Alternatively, for smaller variable surfaces, the signs can use linear drives, means of a wear-free worm gear, directly on the prism.