An innovative robot road construction concept is being unveiled.

By MJ Woof

October 26, 2020

Read time: 2 mins

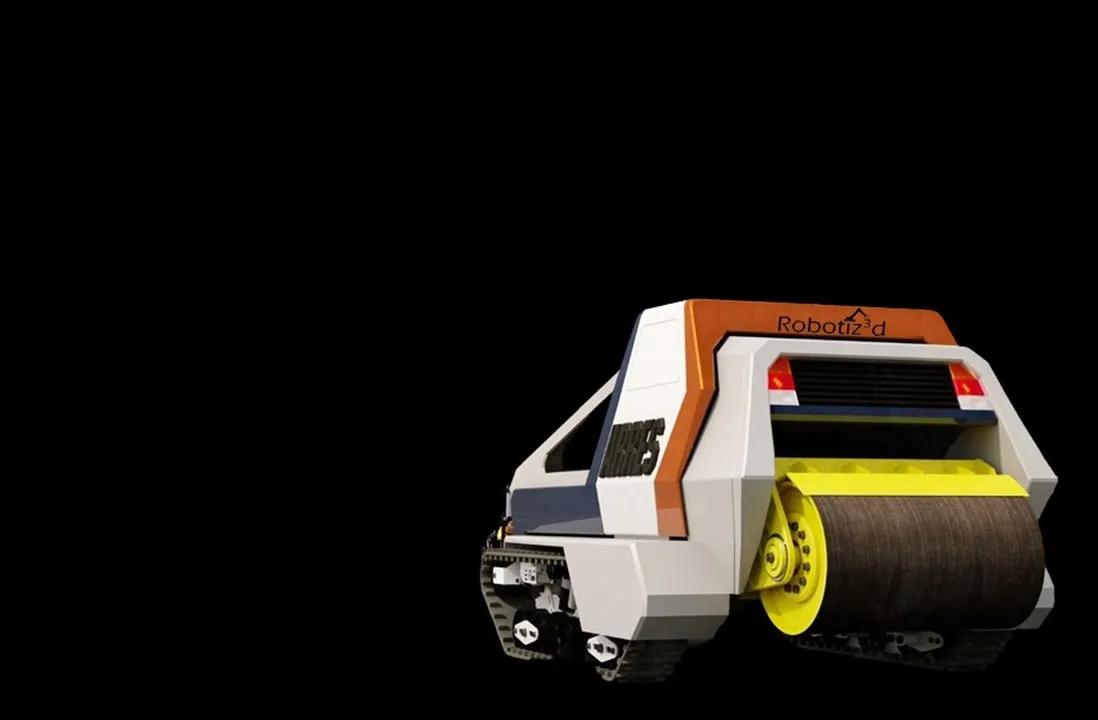

An innovative new concept for robot road construction technology is being unveiled by the University of Liverpool. The university has formed a new spin out company called Robotiz3d, which will develop this advanced technology for road maintenance.

Robotiz3d is a joint venture that has been established in partnership with A2e. The new firm is receiving investment from the University’s Enterprise Investment Fund, alongside private equity investment from a2e.

The company’s aim is to commercialise patented research from the University’s Engineering Robotics Lab. The technology uses Artificial Intelligence and robotics to significantly improve the way road defects, including pot holes and road cracks, are detected and repaired.

Currently, no autonomous technology solutions exist to tackle the pothole crisis which plagues many parts of the country and is estimated to have cost more than £1 billion to repair over the last decade.

Amongst the company founders are Dr Paolo Paoletti and Dr Sebastiano Fichera from the University’s School of Engineering who have an extensive track record of research in this area and have been developing and trialling the technology over the past four years.

Dr Paolo Paoletti, who will serve as chief technology officer for the company, said: “Robotiz3d Ltd will develop an Artificial Intelligence (AI)-driven robotic system to address the national and international potholes problems. The proposed system will be able to autonomously detect and characterize road defects such as cracks and potholes, assess and predict the severity of such defects and fix cracks so that they do not evolve into potholes.”

Dr Sebastiano Fichera, technical director of the company, added: “Current methods to detect and repair of potholes are labour intensive and as such are slow, unsafe, and costly to the economy and environment. The new technology we are developing will make road maintenance tasks faster, cheaper, and cleaner and ultimately make roads safer and more accessible.”

Lisa Layzell, an award winning senior executive and serial entrepreneur of high-tech companies, is a co-founder and CEO of Robotiz3d. She said: “This is an exciting new spin out to take forward. The team at Robotiz3d has the expertise and experience in robotics and AI to deliver the project and introduce world-leading innovation to the management of roads and highways. We have developed a robust business plan to take forward the portfolio of Robotiz3d envisaged products.”