Nearly eight years after Denmark and Germany agreed to construct a major undersea road and rail tunnel, the first contracts are about to be signed. David Arminas reports. Construction is due to start later this year on one of Europe’s most ambitious, as well as the world’s longest, road and rail tunnels, the 17.6km Fehmarnbelt Fixed Link between Germany and Denmark. Fehmarnbelt is expected to cost around US$7.5 billion and be five times the length of the Øresund tunnel between the Danish capital Copenhagen

March 13, 2015

Read time: 7 mins

Nearly eight years after Denmark and Germany agreed to construct a major undersea road and rail tunnel, the first contracts are about to be signed. David Arminas reports

Construction is due to start later this year on one of Europe’s most ambitious, as well as the world’s longest, road and rail tunnels, the 17.6km Fehmarnbelt Fixed Link between Germany and Denmark. Fehmarnbelt is expected to cost around US$7.5 billion and be five times the length of the Øresund tunnel between the Danish capital Copenhagen and the Swedish city of Malmö. When it is finished in 2021, the Fehmarnbelt tunnel will be three times the length of the Trans-Bay Tube Bart Tunnel in San Francisco, which is the world's longest immersed tunnel.

It was June 2007 when the Danish and German ministers for transport signed a declaration of intent to establish a fixed link across the Fehmarnbelt. The original idea was for a bridge, but on environmental grounds a tunnel became the preferred design.

It’s been several years in the planning and pre-qualification stages of contractors. Now, this winter, the first decisions on consortia for the project’s design and build contracts will be taken by4782 Femern, the project’s planning company and a subsidiary of Sund & Bælt Holding, which is wholly owned by the Danish Ministry of Transport. Contractors will handle detailed design, choice of methods and execution based on the concept developed and designed by Femern.

Four large contracts are on offer: dredging of the seabed and land reclamation; construction of the northern section of the tunnel; construction of the southern section; and finally, construction of portal structures, ramps and associated land facilities.

For now, dozens of engineers at Femern are pouring over technical and financial bids from nine pre-qualified consortia, says project director Kim Smedegaard Andersen. “We expect to sign the four major construction contracts when the Construction Act has passed the Danish parliament and German approval is given later this year,” he says. “None of the consortia has bid on the entire project. Some have bid on one contract while others have bid on several.”

The Fehmarnbelt Tunnel will be self-financing by tolls from car and railway traffic. ”A separate contract will be signed in 2016 for the tunnel’s electrical and mechanical installations,” says Andersen. “The winner of this contract will have to operate the tunnel for three years after completion as a maintenance contractor under Femern operation and maintenance management.”

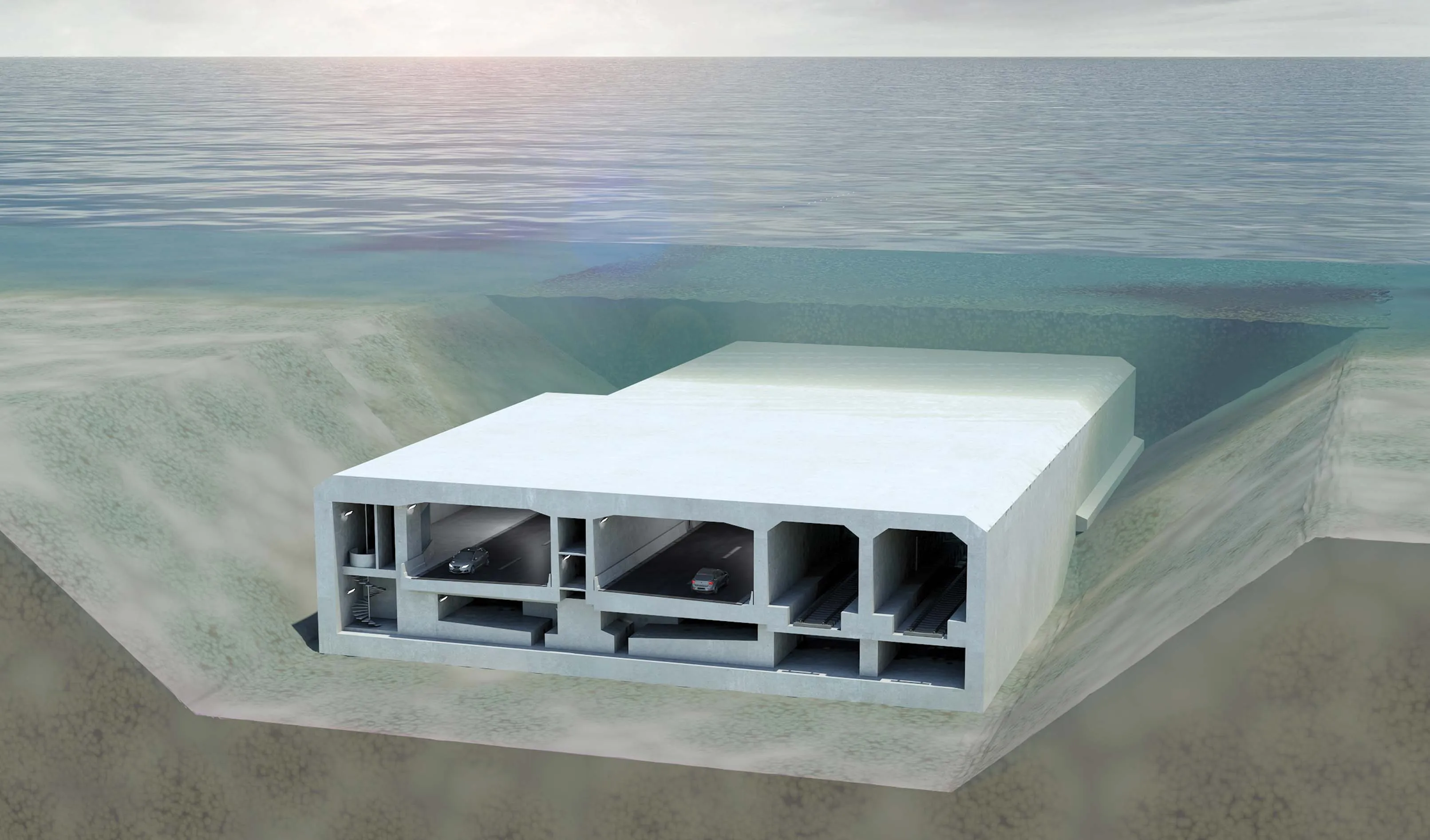

The tunnel will connect the German island of Fehmarn with the Danish island of Lolland, running under the 18km-wide Fehmarn Belt, or Fehmarn Strait, in the Baltic Sea. It will house two divided railway tunnels, two divided motorway tunnels and an emergency tunnel.

The existing ferry takes 45 minutes, not including any waiting time, to cross from Rødbyhavn on Lolland to Puttgarden on Fehmarn. Cars using the tunnel will take around 10 minutes, with no waiting time. Train crossings will take around seven minutes and the new route will cut the train journey between Hamburg and Copenhagen from about four and a half hours to three.

From a safety perspective, Femern claims the immersed tunnel will be safer than equivalent motorways or rail sections on land. There will be no oncoming traffic, no approaches and exits and no disruption as a result of bad weather or darkness.

In a European show of solidarity, last October in Copenhagen, Danish Transport Minister Magnus Heunicke and Anke Spoorendonk, the German Minister of Justice and European Affairs in the neighbouring state of Schleswig-Holstein met to assemble in public a 1:100 scale model of the 89 tunnel elements, or sections. The symbolic construction was part of Fehmarnbelt Days 2014, where hundreds of politicians, business representatives and academics from the region gathered to discuss the benefits of the project.

Construction is due to start later this year. Femern has been conducting extensive soil condition studies in the Fehmarnbelt and the upcoming construction site at Rødbyhavn since 2009. However, more soil studies are needed this summer, including borings between 3m and 10m deep around the coastline. More than 80 other borings, between 10m and 40m deep will be done on the seabed. The data will be used by the dredging contractor as soon as that contract is signed in late summer.

The tunnel itself will consist of 79 standard reinforced concrete sections, called elements, and 10 special elements. All of the 73,000tonne and 217m-long elements will be manufactured at a large seaside production facility likely to be the size of 420 football fields to be built near Rødbyhavn.

The basic element design and production method were developed for the Øresund link, excluding the idea of special elements. These special elements are deeper than the standard elements, around 13m instead of 9m, and wider at 45m instead of around 42m. The extra size is partly because they incorporate a lay-by for maintenance and rescue personnel.

But special elements also have another deck level under the road and rail level. This lower level will hold all the mechanical and electrical equipment. The extra deck also will allow access to all areas of the tunnel for maintenance work so that disruption to traffic is kept to a minimum.

Having special elements means that the standard elements can be technically simpler and virtually identical, making them more suitable for mass production. Eight production lines will be set up so that the elements are produced as if on an assembly line. One element will consist of nine segments, with one segment produced every seventh or eighth day. When a segment is cast, it will be moved along so that the next one can be cast.

Once completed, the element will be pushed into the facility’s coastal basin, towed into the strait and lowered into a pre-dug trench. GPS, echo sounding and ballast tanks along with cables and winches will guide the elements into place. A hydraulic arm will nudge a newly introduced element right up against an in-situ one. The arm is equipped with a hook that grabs hold of a large bracket on the new element and drags it to the previous one.

Each element has a huge rubber gasket at one end to aid in sealing the units in order to pump out water. Gravel and sand fill will cover the elements, as well as a protective layer of stone to be level with the seabed.

Standard elements will be interspersed with the larger cross-sectioned special elements every 2km. Special elements, essentially tunnels underneath the road and rail sections, will hold drainage sumps and plant rooms for electrical and mechanical installations.

Having 10 identical special elements allows the services to be configured in modules that serve half the distance between special elements. This will increase overall system availability and will provide a means of testing and commissioning the services in sequence from the portals to the first special element and to the subsequent special elements.

If this approach is adopted, the workload and risk associated with final testing and fine adjustment, when the final tunnel elements are in place, can be reduced. However, once manufactured, there is little that can be done to change the element structure.

A portal building almost entirely below ground at each end of the tunnel will contain power, water, drainage, radio and telecommunications. A separate Tunnel Power Supply tender covers construction of a turnkey power substation east of Rødbyhavn to supply the tunnel’s technical installations and deliver traction power for the trains.

A six-year construction period is long enough for residents on both islands to be concerned about travel disruptions. To that end, some local roads will be improved and cycle paths laid down. This should also ensure good access to the construction site for personnel and equipment and to ensure that local residents have at least the same opportunities to get around Rødbyhavn during and after the construction phase as they have now.

Construction is due to start later this year on one of Europe’s most ambitious, as well as the world’s longest, road and rail tunnels, the 17.6km Fehmarnbelt Fixed Link between Germany and Denmark. Fehmarnbelt is expected to cost around US$7.5 billion and be five times the length of the Øresund tunnel between the Danish capital Copenhagen and the Swedish city of Malmö. When it is finished in 2021, the Fehmarnbelt tunnel will be three times the length of the Trans-Bay Tube Bart Tunnel in San Francisco, which is the world's longest immersed tunnel.

It was June 2007 when the Danish and German ministers for transport signed a declaration of intent to establish a fixed link across the Fehmarnbelt. The original idea was for a bridge, but on environmental grounds a tunnel became the preferred design.

It’s been several years in the planning and pre-qualification stages of contractors. Now, this winter, the first decisions on consortia for the project’s design and build contracts will be taken by

Four large contracts are on offer: dredging of the seabed and land reclamation; construction of the northern section of the tunnel; construction of the southern section; and finally, construction of portal structures, ramps and associated land facilities.

For now, dozens of engineers at Femern are pouring over technical and financial bids from nine pre-qualified consortia, says project director Kim Smedegaard Andersen. “We expect to sign the four major construction contracts when the Construction Act has passed the Danish parliament and German approval is given later this year,” he says. “None of the consortia has bid on the entire project. Some have bid on one contract while others have bid on several.”

The Fehmarnbelt Tunnel will be self-financing by tolls from car and railway traffic. ”A separate contract will be signed in 2016 for the tunnel’s electrical and mechanical installations,” says Andersen. “The winner of this contract will have to operate the tunnel for three years after completion as a maintenance contractor under Femern operation and maintenance management.”

The tunnel will connect the German island of Fehmarn with the Danish island of Lolland, running under the 18km-wide Fehmarn Belt, or Fehmarn Strait, in the Baltic Sea. It will house two divided railway tunnels, two divided motorway tunnels and an emergency tunnel.

The existing ferry takes 45 minutes, not including any waiting time, to cross from Rødbyhavn on Lolland to Puttgarden on Fehmarn. Cars using the tunnel will take around 10 minutes, with no waiting time. Train crossings will take around seven minutes and the new route will cut the train journey between Hamburg and Copenhagen from about four and a half hours to three.

From a safety perspective, Femern claims the immersed tunnel will be safer than equivalent motorways or rail sections on land. There will be no oncoming traffic, no approaches and exits and no disruption as a result of bad weather or darkness.

In a European show of solidarity, last October in Copenhagen, Danish Transport Minister Magnus Heunicke and Anke Spoorendonk, the German Minister of Justice and European Affairs in the neighbouring state of Schleswig-Holstein met to assemble in public a 1:100 scale model of the 89 tunnel elements, or sections. The symbolic construction was part of Fehmarnbelt Days 2014, where hundreds of politicians, business representatives and academics from the region gathered to discuss the benefits of the project.

Construction is due to start later this year. Femern has been conducting extensive soil condition studies in the Fehmarnbelt and the upcoming construction site at Rødbyhavn since 2009. However, more soil studies are needed this summer, including borings between 3m and 10m deep around the coastline. More than 80 other borings, between 10m and 40m deep will be done on the seabed. The data will be used by the dredging contractor as soon as that contract is signed in late summer.

The tunnel itself will consist of 79 standard reinforced concrete sections, called elements, and 10 special elements. All of the 73,000tonne and 217m-long elements will be manufactured at a large seaside production facility likely to be the size of 420 football fields to be built near Rødbyhavn.

The basic element design and production method were developed for the Øresund link, excluding the idea of special elements. These special elements are deeper than the standard elements, around 13m instead of 9m, and wider at 45m instead of around 42m. The extra size is partly because they incorporate a lay-by for maintenance and rescue personnel.

But special elements also have another deck level under the road and rail level. This lower level will hold all the mechanical and electrical equipment. The extra deck also will allow access to all areas of the tunnel for maintenance work so that disruption to traffic is kept to a minimum.

Having special elements means that the standard elements can be technically simpler and virtually identical, making them more suitable for mass production. Eight production lines will be set up so that the elements are produced as if on an assembly line. One element will consist of nine segments, with one segment produced every seventh or eighth day. When a segment is cast, it will be moved along so that the next one can be cast.

Once completed, the element will be pushed into the facility’s coastal basin, towed into the strait and lowered into a pre-dug trench. GPS, echo sounding and ballast tanks along with cables and winches will guide the elements into place. A hydraulic arm will nudge a newly introduced element right up against an in-situ one. The arm is equipped with a hook that grabs hold of a large bracket on the new element and drags it to the previous one.

Each element has a huge rubber gasket at one end to aid in sealing the units in order to pump out water. Gravel and sand fill will cover the elements, as well as a protective layer of stone to be level with the seabed.

Standard elements will be interspersed with the larger cross-sectioned special elements every 2km. Special elements, essentially tunnels underneath the road and rail sections, will hold drainage sumps and plant rooms for electrical and mechanical installations.

Having 10 identical special elements allows the services to be configured in modules that serve half the distance between special elements. This will increase overall system availability and will provide a means of testing and commissioning the services in sequence from the portals to the first special element and to the subsequent special elements.

If this approach is adopted, the workload and risk associated with final testing and fine adjustment, when the final tunnel elements are in place, can be reduced. However, once manufactured, there is little that can be done to change the element structure.

A portal building almost entirely below ground at each end of the tunnel will contain power, water, drainage, radio and telecommunications. A separate Tunnel Power Supply tender covers construction of a turnkey power substation east of Rødbyhavn to supply the tunnel’s technical installations and deliver traction power for the trains.

A six-year construction period is long enough for residents on both islands to be concerned about travel disruptions. To that end, some local roads will be improved and cycle paths laid down. This should also ensure good access to the construction site for personnel and equipment and to ensure that local residents have at least the same opportunities to get around Rødbyhavn during and after the construction phase as they have now.