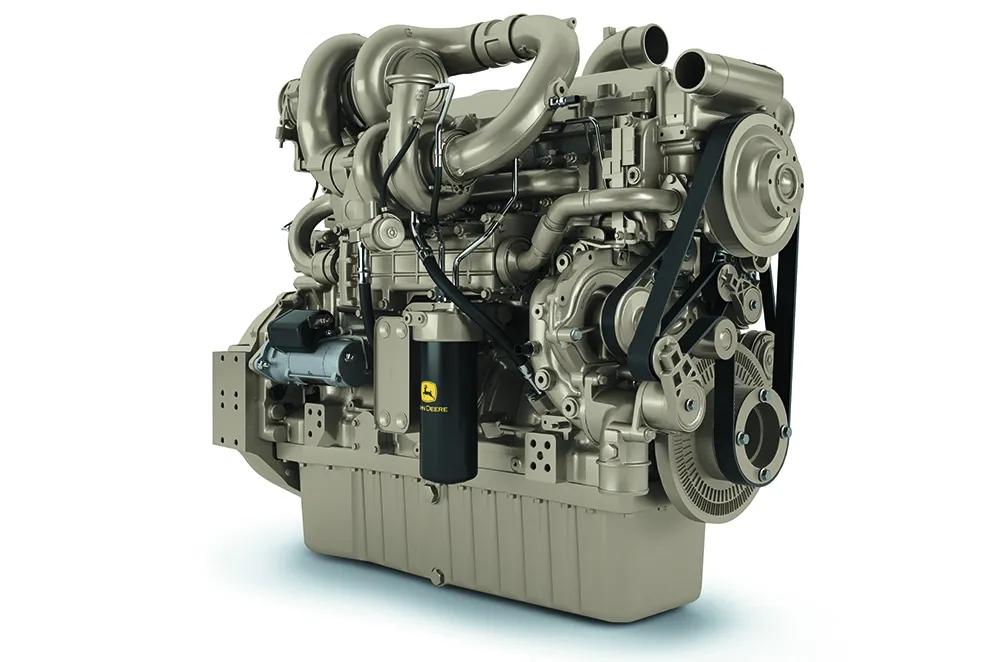

Atlas Copco is upgrading its mid-sized compressors for the construction industry with new features including the use of the latest Deutz engines. The new XAHS 237+ compressor delivers air at 12bars and a rate of 236litres/sec while the XAMS 287+ is rated at 8.6bars and delivers a flow rate of 285litres/sec. The engines are said to feature good fuel economy due to the use of the innovative and proven FuelXpert system, which regulates speed and air intake. Other features include centralised fluid drains, acce

February 6, 2012

Read time: 1 min