The

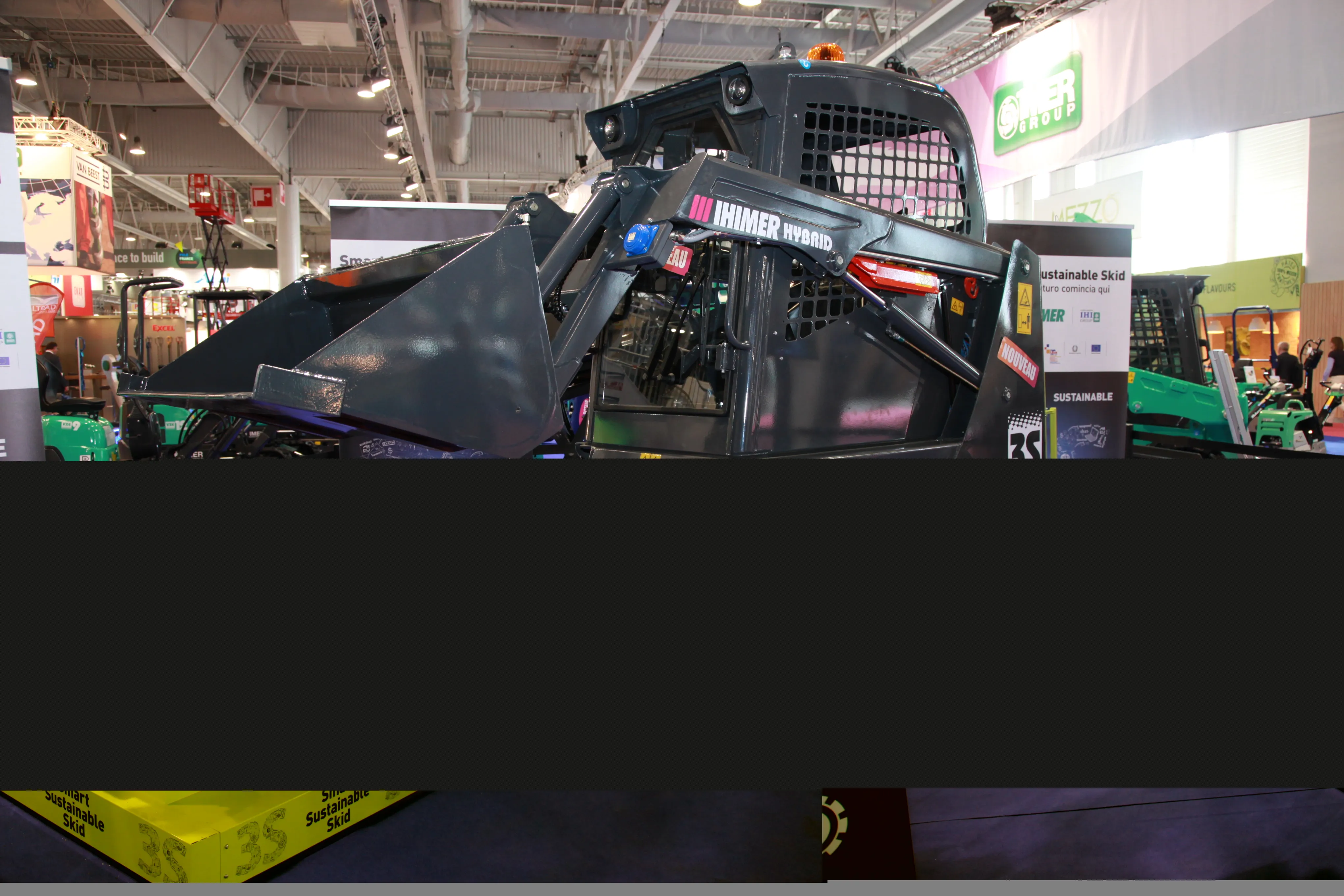

The prototype is the culmination of a development programme which has involved both Pisa and Florence Universities, said Paolo Pianigiani, director of the IMER Access business unit. Following on from the skid steers, access platforms will be the next IMER products to benefit from hybrid technology followed by mini excavators.

“The aim was to develop power units which then could be used on other products in our company,” explained Pianigiani. “There could be a wide spectrum of uses.” IMER has four divisions: earthmoving, access platforms, small equipment and concrete.

With an operating weight of 1,330kg, the 3S has an operating load of 330kg and delivers a breakout force of 750 kgf. Power is stored in a lithium ferro phosphate battery pack 90 Ah 86 V, which provides a range of two hours with a 7 kW Worms Expert 7510X on-board auxiliary power unit.

The drive control system, which was developed in the access business of the company, sees the four independent wheels controlled electronically, managing power delivery according to the actual demand. “The integration of the hybrid technology and the drive system allows you to have better control of the traction and consequently safer operation,” said Pianigiani.

The unit, which should be in production by the end of the year, will be useful in a wide range of applications, said Pianigiani from landscaping, maintenance and civil works to use by the army - as it can be operated remotely if required.