Caterpillar is setting up a regional training centre in Dubai. This new technical and sales training centre will be used to support more than 7,000 Cat dealer technicians in the Africa and Middle East (AME) Region. The company is investing over US$7 million in the facility, which will cover an area of about 1,700m2 and employ 40 personnel. Most of the team will be high-level technical staff who will primarily be recruited from the region.

The facility will help support the technicians at AME Cat dealer

July 28, 2015

Read time: 2 mins

This new technical and sales training centre will be used to support more than 7,000 Cat dealer technicians in the Africa and Middle East (AME) Region. The company is investing over US$7 million in the facility, which will cover an area of about 1,700m2 and employ 40 personnel. Most of the team will be high-level technical staff who will primarily be recruited from the region.

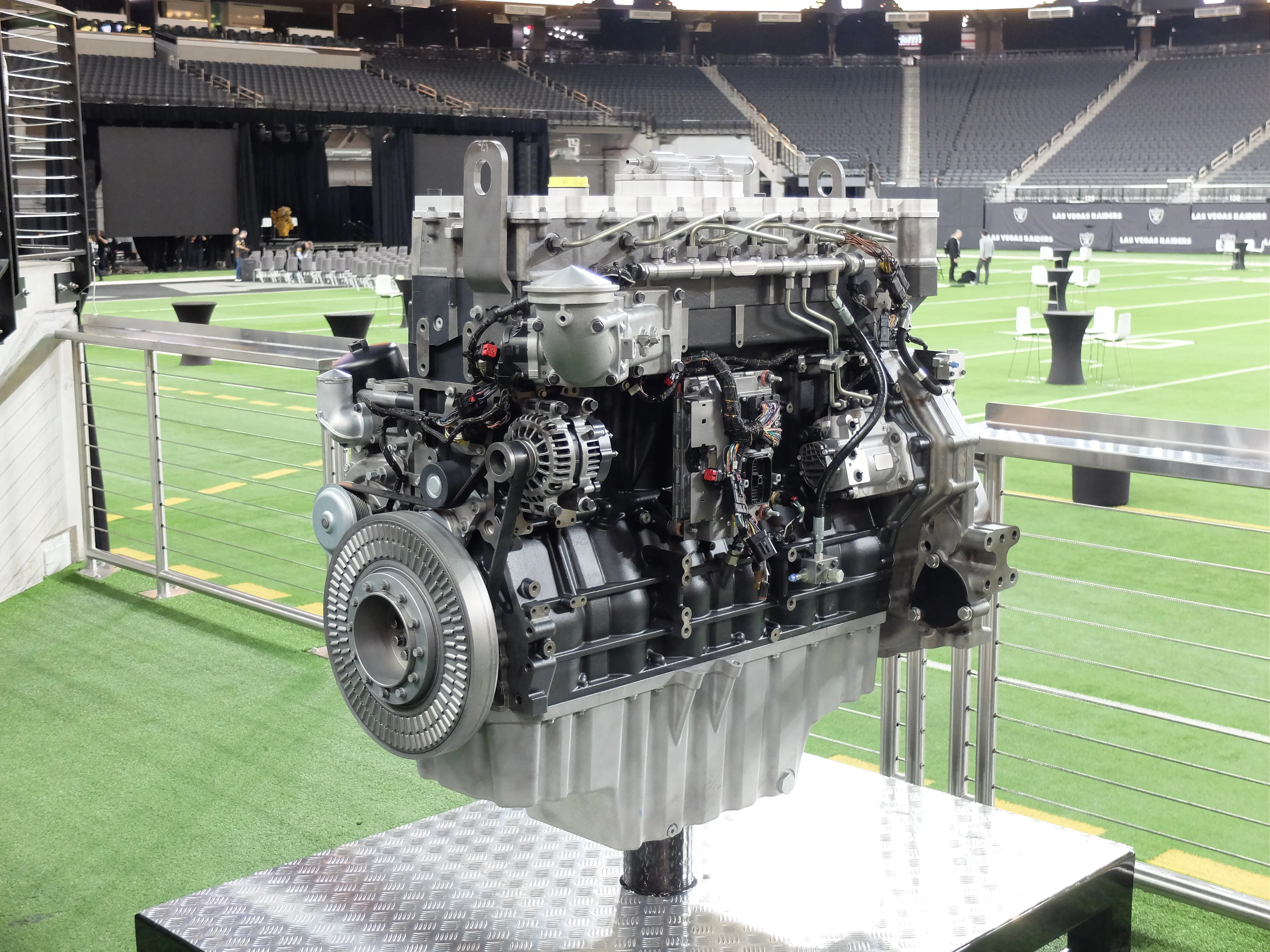

The facility will help support the technicians at AME Cat dealers. Caterpillar said that the training the technicians will receive at the new facility in Dubai will help to develop their skills and knowledge on both product and the latest product support technologies.

“Our training centre in Dubai is a key part of our plans for the Middle East and Africa and will ensure Caterpillar and our dealers can be relied upon for providing unsurpassed support to our customers. This is an important region for Caterpillar and we expect to see strong, continued growth for our customers, and we will grow to support that,” commented Nigel Lewis, vice president with responsibility for Caterpillar’s Europe, Africa and Middle East (EAME) Distribution Division.

The centre will also feature a lab for scheduled oil sampling analysis that will help meet critical customer-required turnaround time of emergency samples and reduce downtime of Caterpillar products in the region. The facility will be located at Caterpillar's Middle East parts distribution centre and regional sales and marketing office in Jebel Ali, Dubai.

The facility is expected to be operational in the last quarter of this year.