Astec Industries has unveiled “optimistic plans” for India where the government plans to spend US$600 billion on infrastructure in the coming years. Recently, four US-based companies of Astec Industries hosted two senior executives of Tractors India Limited (TIL) to further cooperation initiatives and strengthen Astec’s market position in India. Utilising its newly-opened state-of-the-art 20,000m² production facility in Kharagpur, West Bengal, TIL will manufacture a range of Astec Aggregate and Mining crush

December 4, 2012

Read time: 2 mins

Astec Industries has unveiled “optimistic plans” for India where the government plans to spend US$600 billion on infrastructure in the coming years.

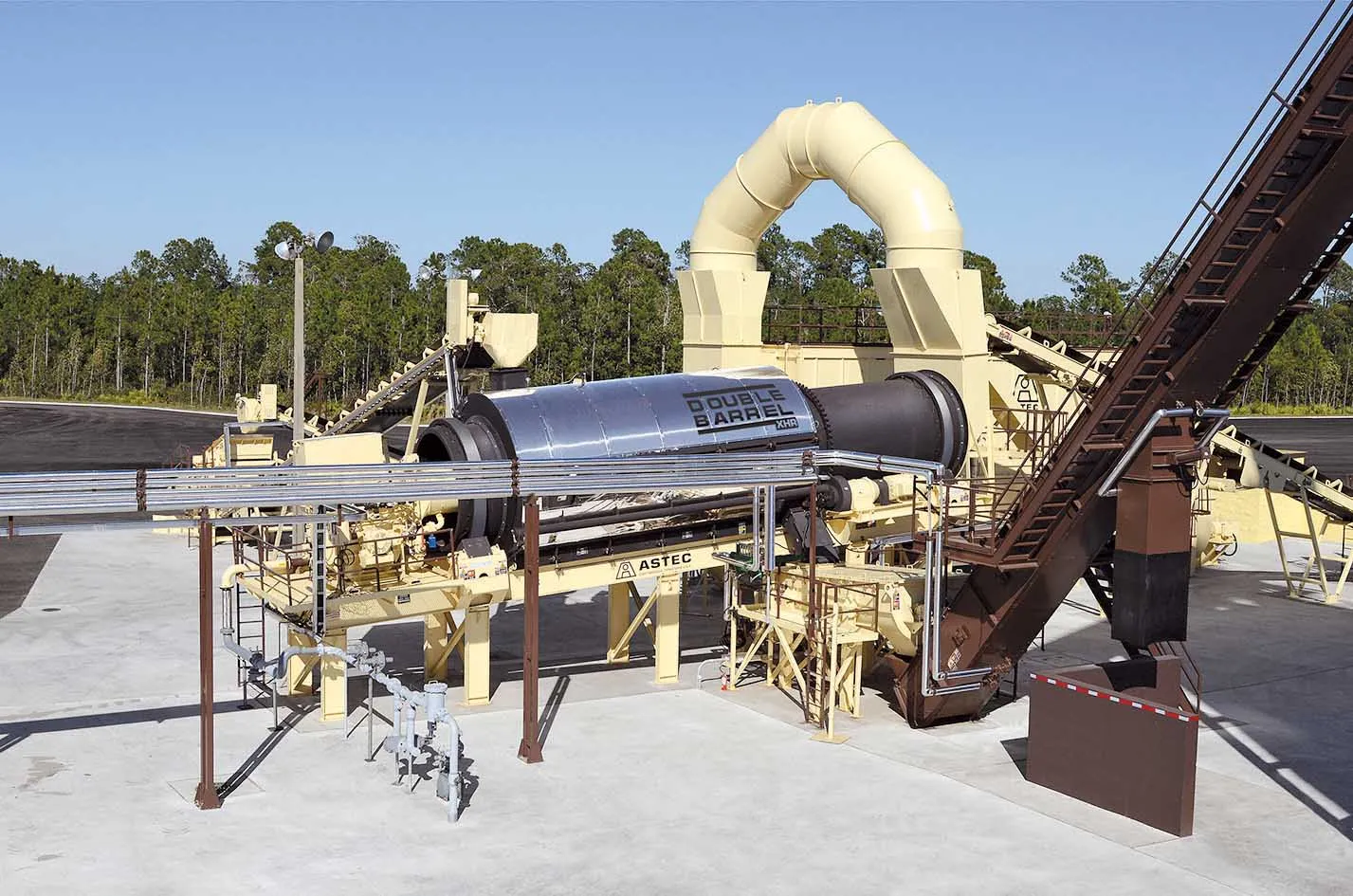

Recently, four US-based companies ofUtilising its newly-opened state-of-the-art 20,000m² production facility in Kharagpur, West Bengal, TIL will manufacture a range of Astec Aggregate and Mining crushing and screening equipment and Astec asphalt hot mix plants, including track, portable and static plants and Double Barrel track plants.

Visitors to the Astec facilities included Sumit Mazumder, vice chairman and managing director TIL and Somnath Bhattacharjee, president of material handling solutions equipment and project solutions business at TIL.

Strategic discussions included new product review, expanded training, cooperative manufacturing, and key marketing initiatives in India.

TIL is an authorised licensee for manufacturing, sales and distribution of

“We have very optimistic plans for Astec group of crushing and screening and hot mix plants in India. This visit is an important step in strengthening our partnership as it allows us to review our business strategy for India and capture best practices used by the Astec group which can be localised and implemented for the benefit of customers in India,” said Mazumder.

Rick Patek, group vice president of the Astec Aggregate and Mining, said: “With a continued growth of an Indian economy projected at 7% in 2013 and its booming crushing and screening market, we see India as an important component of our overall global expansion strategy. The Indian government’s 12th Five-Year Plan’s objective to invest $600 billion in the infrastructure segment highlights the growing construction and aggregate needs in India. We look forward to responding to these ongoing needs by providing localised application solutions to end-users in the market.”