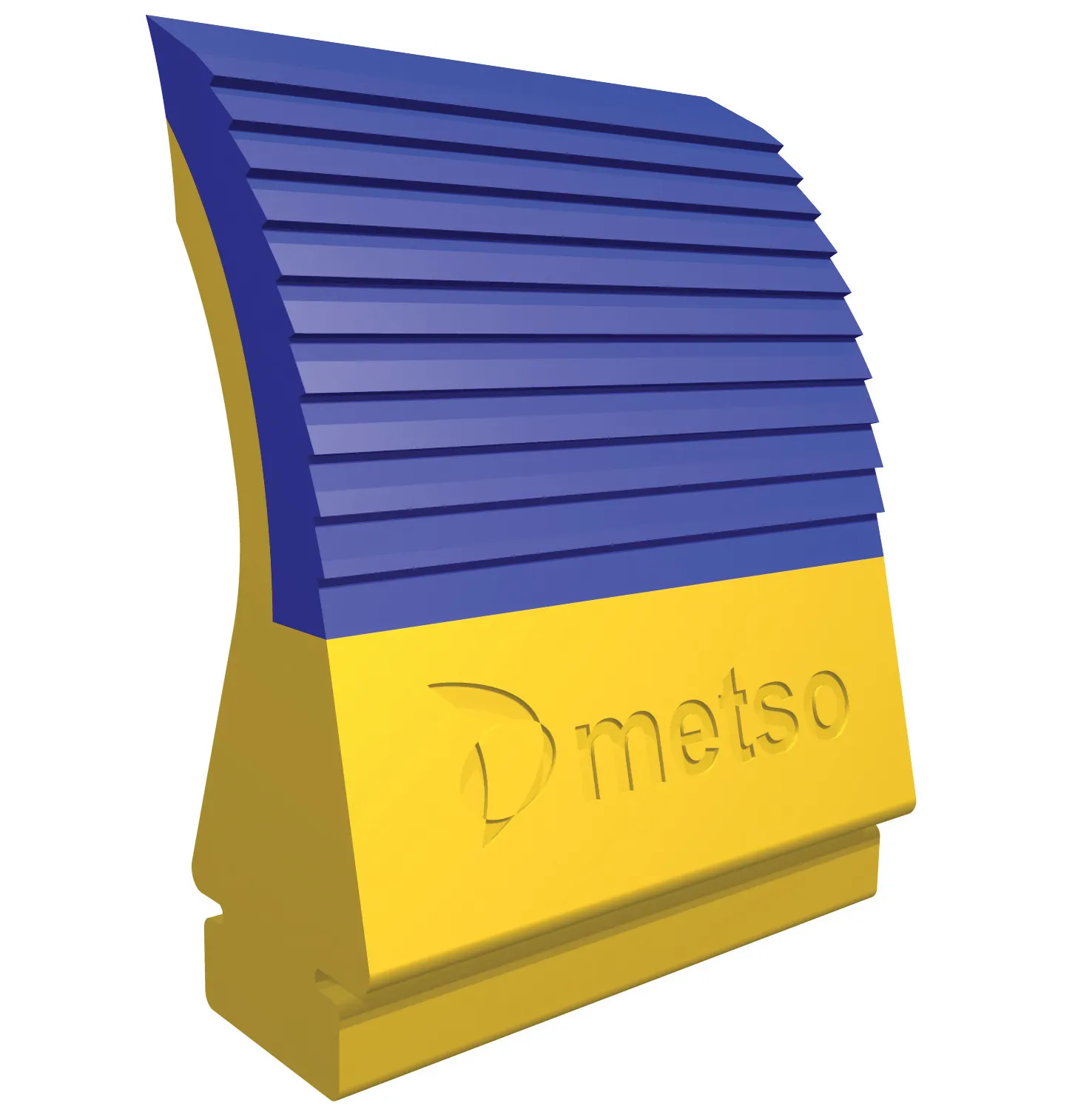

Metso has launched its redesigned Trellex ABC 70 belt scraper – said to have 25% more wear life and improved stability and performance. The Trellex ABC 70 is also said by Metso to be more easily available to “hard working quarries worldwide”. Fully compatible with other Trellex Pre-Cleaner such as ABC 90 and ABC 95, the ABC 70 ensures that no mechanical alterations are necessary if changing to a di fferent blade type.

June 20, 2012

Read time: 1 min

The Trellex ABC 70 is also said by Metso to be more easily available to “hard working quarries worldwide”. Fully compatible with other Trellex Pre-Cleaner such as ABC 90 and ABC 95, the ABC 70 ensures that no mechanical alterations are necessary if changing to a di fferent blade type.