These latest variants are suited for use in machines such as cranes, crushers and screening equipment.

These engines are offered with outputs from 75–503kW and can be delivered as a complete and ready-made package. This comprises an engine, exhaust aftertreatment system, radiator and cooling system, plus auxiliaries such as mountings, hoses and an air cleaner. More than 60% of the content is pre-approved, making the machine integration process simpler and quicker.

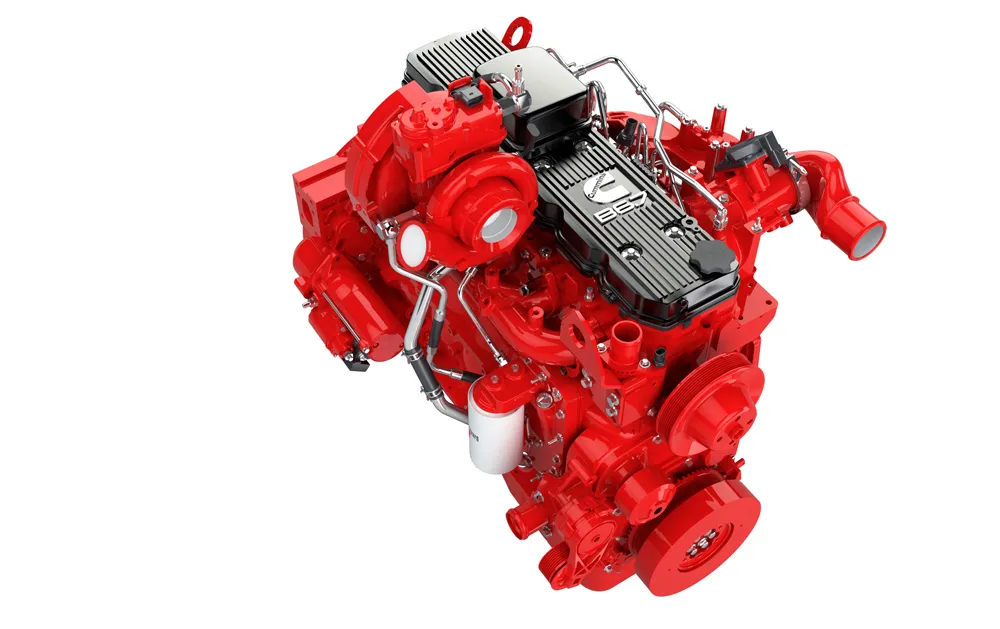

The Performance Series power units offer an ultra-clean, flexible drop-in solution for manufacturers. The engines offer high-power densities for tough applications such as crushing, screening and pumping. To increase the flexibility and capability of the power units, new single and dual rear-engine power take-offs (REPTO) are being added. These complement the standard PTO capability used for items such as hydraulic pumps and will be available on Cummins base engines as well as power units.

As an example, fitted with the dual REPTO, the L9 will have a total drive capability of 560Nm. This will make the engine capable of driving additional pumping capability through SAE B 2 and 4 bolt mounts. Integrated into the flywheel housing the dual REPTO is compact and has a minimal impact on engine packaging. Added weight is approximately 100kg. Equipment manufacturers will have the ability to efficiently drive more from the engine without the need for additional aftermarket systems. This supports driving of hydraulic pumps for many machine functions from steering systems to fans. It also reduces installation costs and complexity, for a more integrated solution.