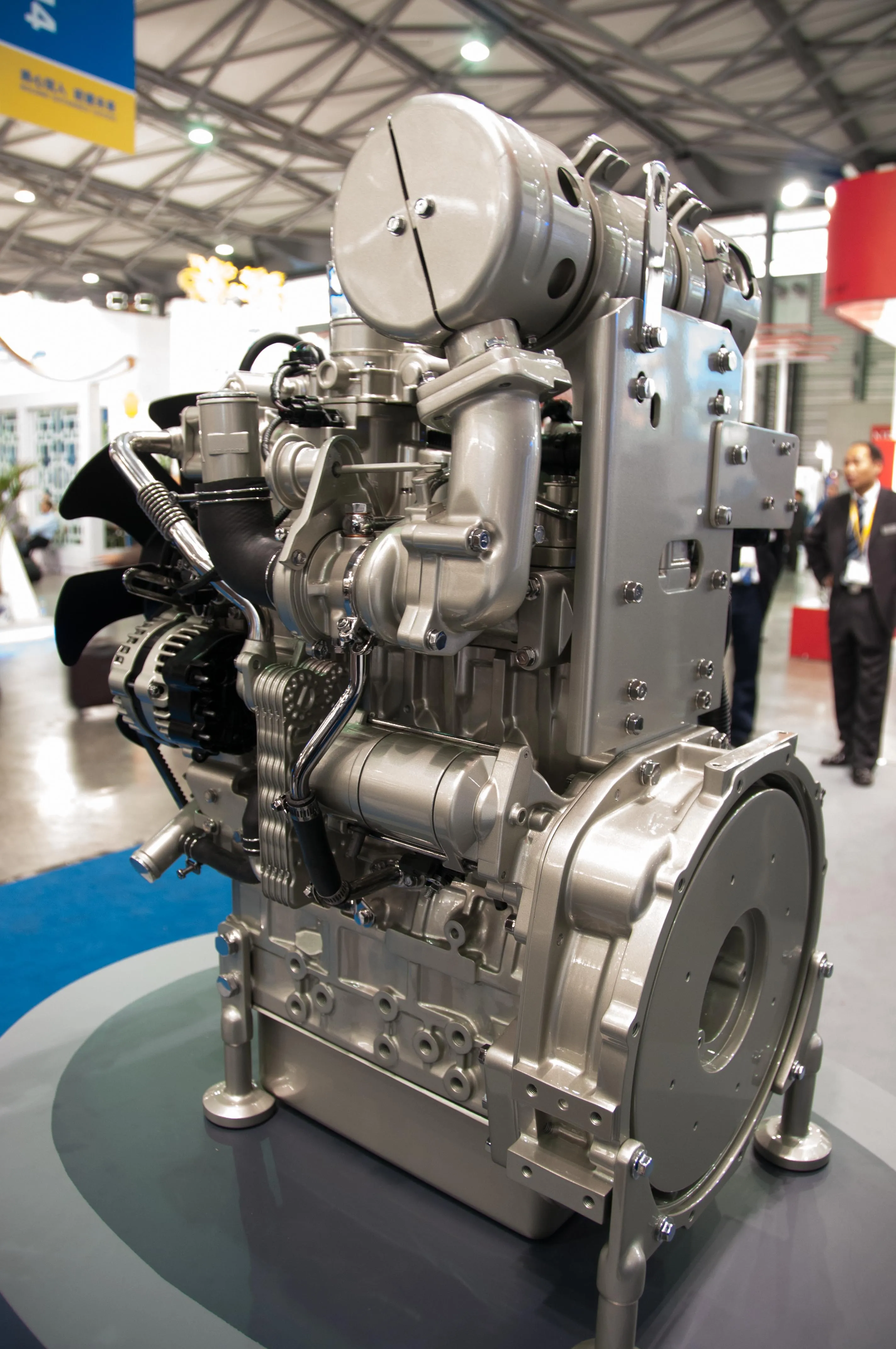

“In western markets buyers are looking for smaller machines for tighter turning circles and better safety on site,” explained Oliver Lythgoe, marketing manager at Perkins. The smaller engine helps OEMs achieve this objective.

The engine has a 7% reduction in fuel usage over the previous model. Perkins however is keen to work closely with OEMs to ensure good integration. With good integration of hydraulics and electrics greater fuel economy and productivity can be achieved. Thousands of hours were clocked up validating the engine in real life conditions and climate extremes. With one integration 20% fuel savings were achieved. Another customer commented it was “the best tier 4 installation they had ever had.”

Primary markets are seen as small excavators of up to 8 tonnes, small wheel loaders and other compact construction equipment. Typically in this sector around half the sales are to rental companies and the rest to small businesses. Rental companies are after no hassle machines with long servicing intervals and no diesel particle filters.