Better damage resistance, increased wear life and more distance in an hour are just three claims Jock Aitken,

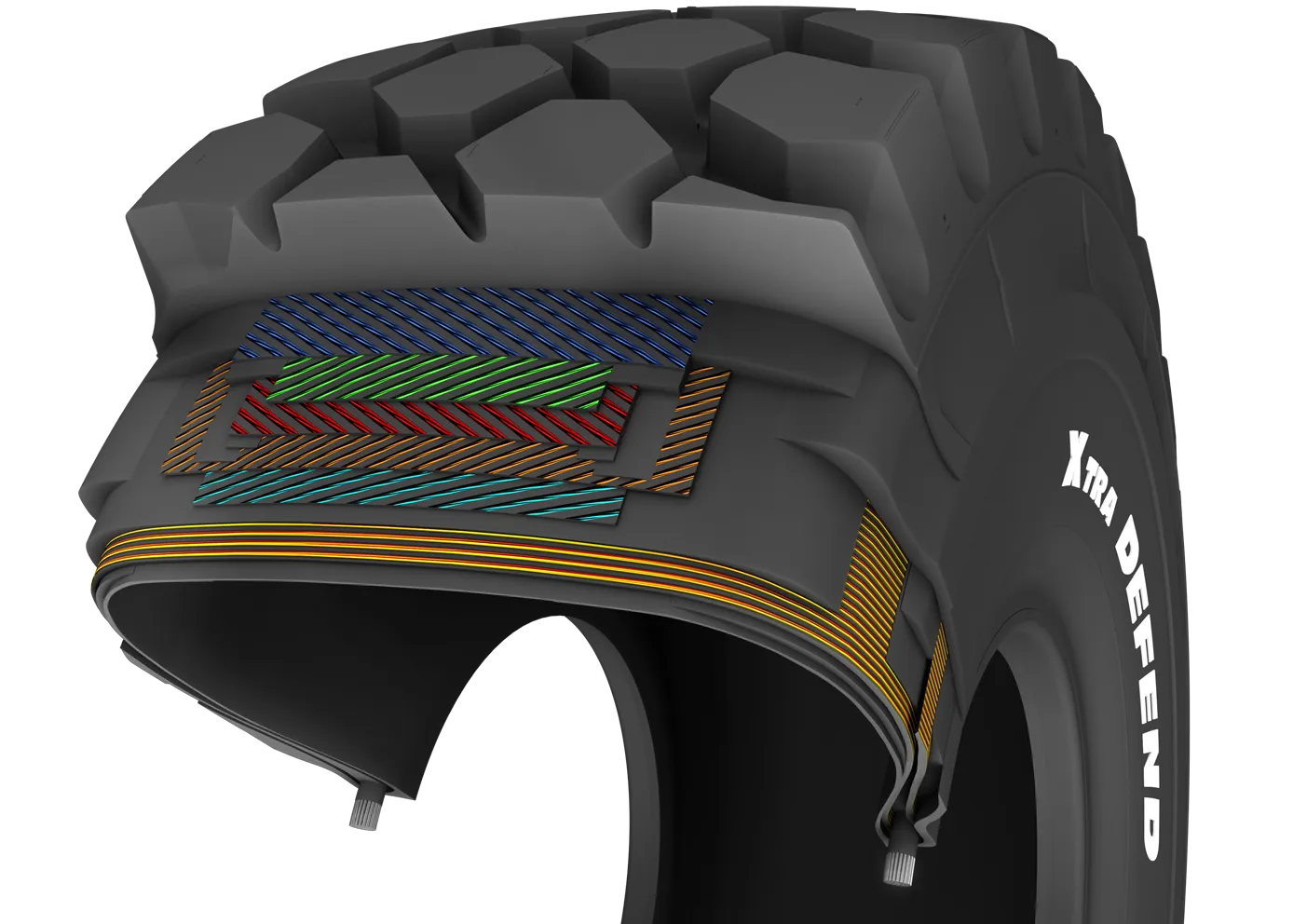

Referring to the cables used on the ADT Xtra Defend tyre (XDT) there is a 15% wear life and increased damage resistance. The XDT has 25% more steel in each cable, making it a much more damage resistant casing. The mass and the sidewall are 15% thicker than the previous one”, he explained.

He added that it is not just the tread that matters, but the amount of rubber available to be used as tread. When compared to their previous offer, the X Super Trade Plus, there is now 17% more available rubber to be used. The XDT also runs cool which means it lasts longer.

The puncture resistance is at 172mm, a 16mm difference with competitor

“It's heavier so you’d think automatically it must be generating more heat, but we can dissipate that quickly, so it’s a cool running tyre," Aitken concluded.

Speaking about Michelin's new RDT traction offer and the first three-star tyre on the market: the Grip, and its rock offer: the Protect, Aitken explained their availability in the UK and Ireland as an A4 compound for aggressive weather conditions and how the Nordic countries use the B compound for covering longer distances.

The same casing is on both with an increase of carrying capacity and an increase in distance in an hour. "You shouldn’t be able to do that; the two should be mutually exclusive. This is a huge breakthrough for us".

Highlighting the need for excellent grip in loose conditions, Aitken said the design gives 30% greater leading edges, enabling them to dig their heels in, making it a better-suited tyre to move forward and perform as a mud plugger.

"With the previous offer, the A4 XPT, we said it could go to 18km/h. With the new tyre's three-star casing: 22km/h - an increase of a fifth. In the B compound the traction and extraction which was a B compound to 22km/h, the extra-low grip takes it to 34km/h - a 54% increase - and you can take a higher load, it's more damage resistant, and the tread will last longer."

The Xtra load grip traction offer has 17% more rubber available to be used than the previously offerred XDT. In addition, the stable contact patch leaves little movement in the contact area which means it’s going to run cool and last for a long time.

"However, this is the star of the show: the Perrota proof cables," he added. Through surrounding cables in rubber and twisting them together, you reduce damage caused by rain that causes rust and prevents the capillary action of high filaments drawing moisture, making it extremely resistant to fatal damage, and the casing more acceptable for retreading. This allows 8% more wear life and more distance in an hour."

Meanwhile, Michelin's new rock offer has 9% more available rubber to use than the previous X Quarry S and a greater 60% distance in an hour allied to a greater carrying capacity. Aitken states this means an improved TKPH because as you increase the load and you can increase the speed.

Referring to the tread pattern, the tyre is also braced underneath to form an almost continuous single block. "Because we’ve braced it so well we have a large footprint with little movement in the tread. To have that with a deeper tread and more tread rubber available and tread rubber is relatively dense and a good heat sync; that’s sort of witchcraft."

Aitken summarises that having all this and a reduction in heat leads to better damage resistance, more wear, distance, speed, and load which means increased productivity.