Both Atlas Copco and Hitachi have selected new low emission engines for some of their latest machines being made available in Europe and North America. For Atlas Copco, this has seen the firm installing diesels from John Deere Power Systems to drive a number of its new air compressors. Meanwhile Hitachi is now installing Deutz diesels in a number of its new wheeled loaders.

The John Deere PowerTech Tier 4 Final /Stage IV engines will power three new air compressors from Atlas Copco. The Atlas Copco XAS 7

December 17, 2014

Read time: 3 mins

Both Atlas Copco and Hitachi have selected new low emission engines for some of their latest machines being made available in Europe and North America. For Atlas Copco, this has seen the firm installing diesels from John Deere Power Systems to drive a number of its new air compressors. Meanwhile Hitachi is now installing Deutz diesels in a number of its new wheeled loaders.

The257 John Deere PowerTech Tier 4 Final /Stage IV engines will power three new air compressors from 161 Atlas Copco. The Atlas Copco XAS 750, XAS 1800 and XATS 1050 JD compressors are designed to deliver high productivity in demanding applications and production of the units is commencing in 2015.

The Final Tier 4/Stage IV XAS 750 air compressor will feature the PowerTech PVS 6.8L engine, rated at 187kW, while the Final Tier 4/Stage IV XAS 1800 will be driven by the PowerTech PSS 13.5L engine, rated at 393kW. The all new XATS 1050 JD will include the PowerTech PSS 9.0L engine, rated at 242kW.

The new Final Tier 4/Stage IV compressors will join a range of Atlas Copco compressors powered by John Deere engines. Atlas Copco and John Deere have partnered on air compressor solutions since the 1990s. Throughout the transitions between tiers, John Deere has worked closely with Atlas Copco on developing engines optimised for the application.

To meet increasingly stringent regulations, John Deere has systematically adopted technologies for each regulatory tier. To conform with Final Tier 4/ Stage IV requirements in the 93kW and above power range, John Deere configured an Integrated Emissions Control system with cooled exhaust gas recirculation (EGR), a diesel oxidation catalyst (DOC)/ diesel particulate filter (DPF) and selective catalytic reduction (SCR).

In addition to emissions compliance, the John Deere Final Tier 4/Stage IV solutions are said to offer Atlas Copco improved transient response time, proven reliability and low diesel exhaust fluid (DEF) consumption (1-3%) compared to diesel fuel consumption. Also, John Deere variable-speed fan technology contributes to less noise, lower fuel consumption and improved durability of belts and pulleys.

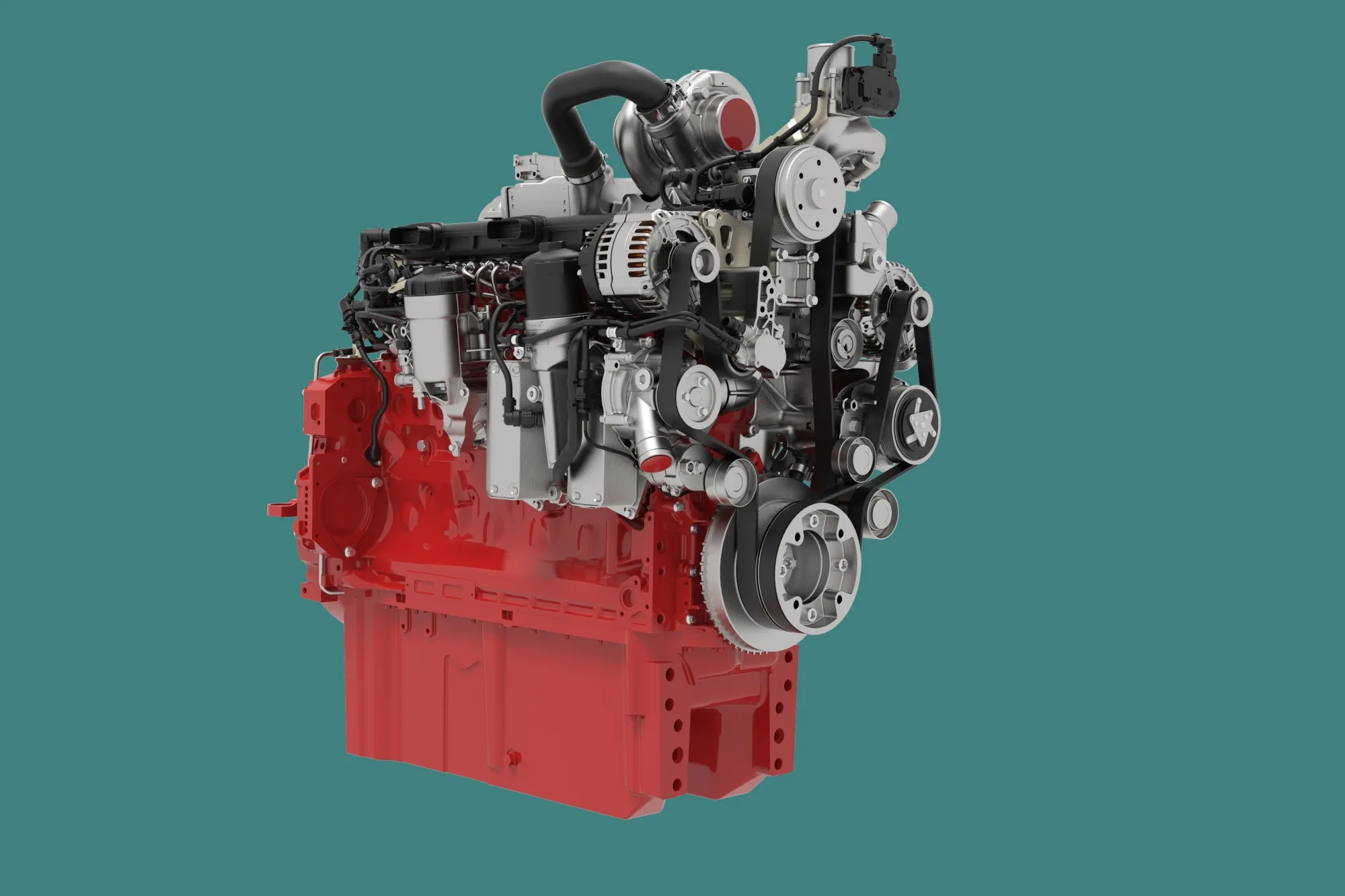

Meanwhile233 Hitachi Construction Machinery (HCM) is now fitting 201 Deutz TCD 3.6 engines to its ZW100 and ZW120 wheeled loaders. The partnership with HCM is of significant benefit to Deutz as it will boost the engine firm’s international presence, particularly in the Japanese market.

The TCD 3.6 engine now fitted in the ZW100 and ZW120 wheeled loaders can be rated at outputs of 55.4-90kW at 2,300 rpm,. The engine was selected by HCM as it is compact and has a modular exhaust after-treatment system (DOC), which can be mounted on the engine as an optional extra, simplifying equipment integration. The TCD 3.6 is fitted with a charge air cooler and meets the EU Stage III B and US EPA Tier 4 Interim emissions standards just with an oxidising catalytic converter.

The

The Final Tier 4/Stage IV XAS 750 air compressor will feature the PowerTech PVS 6.8L engine, rated at 187kW, while the Final Tier 4/Stage IV XAS 1800 will be driven by the PowerTech PSS 13.5L engine, rated at 393kW. The all new XATS 1050 JD will include the PowerTech PSS 9.0L engine, rated at 242kW.

The new Final Tier 4/Stage IV compressors will join a range of Atlas Copco compressors powered by John Deere engines. Atlas Copco and John Deere have partnered on air compressor solutions since the 1990s. Throughout the transitions between tiers, John Deere has worked closely with Atlas Copco on developing engines optimised for the application.

To meet increasingly stringent regulations, John Deere has systematically adopted technologies for each regulatory tier. To conform with Final Tier 4/ Stage IV requirements in the 93kW and above power range, John Deere configured an Integrated Emissions Control system with cooled exhaust gas recirculation (EGR), a diesel oxidation catalyst (DOC)/ diesel particulate filter (DPF) and selective catalytic reduction (SCR).

In addition to emissions compliance, the John Deere Final Tier 4/Stage IV solutions are said to offer Atlas Copco improved transient response time, proven reliability and low diesel exhaust fluid (DEF) consumption (1-3%) compared to diesel fuel consumption. Also, John Deere variable-speed fan technology contributes to less noise, lower fuel consumption and improved durability of belts and pulleys.

Meanwhile

The TCD 3.6 engine now fitted in the ZW100 and ZW120 wheeled loaders can be rated at outputs of 55.4-90kW at 2,300 rpm,. The engine was selected by HCM as it is compact and has a modular exhaust after-treatment system (DOC), which can be mounted on the engine as an optional extra, simplifying equipment integration. The TCD 3.6 is fitted with a charge air cooler and meets the EU Stage III B and US EPA Tier 4 Interim emissions standards just with an oxidising catalytic converter.