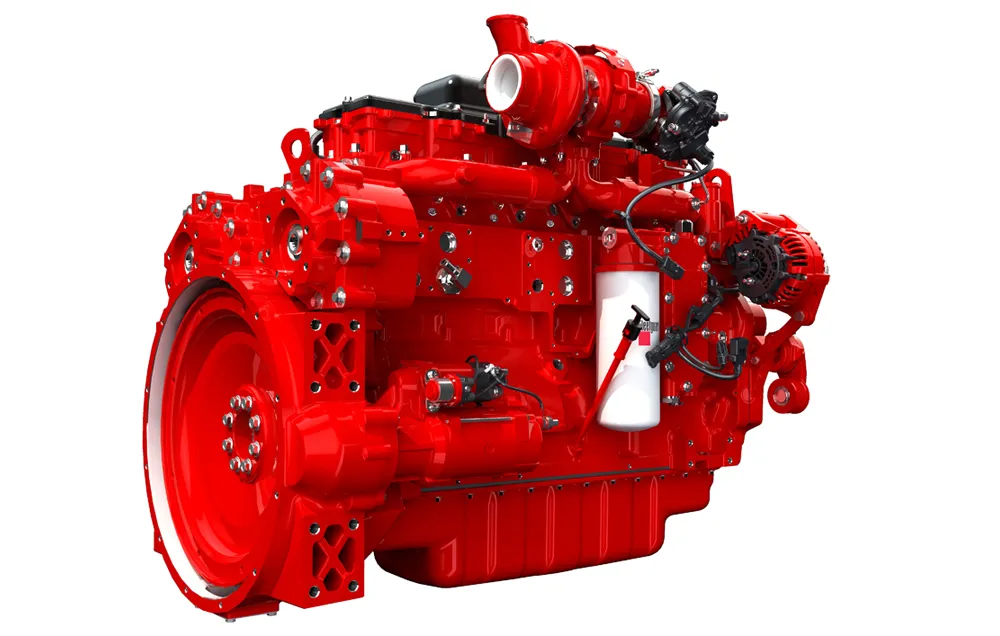

These power units are available with output ratings from 75–503kW, delivered as a complete and ready-made package. This comprises an engine, exhaust aftertreatment system, radiator and cooling system, plus auxiliaries such as mounting feet, hoses and an air cleaner. More than 60% of the content is pre-approved, which is said to make the machine integration process simpler and quicker.

These engines have higher power densities than previous units, suiting them to hard- working applications such as crushing, screening and pumping.

To increase the flexibility and capability of the power units, the firm has integrated the new single and dual rear-engine power take-offs (REPTO). These complement their standard PTO capability used for items such as hydraulic pumps.

As an example, fitted with the dual REPTO, the L9 will have a total drive capability of 560Nm. Integrated into the flywheel housing the dual REPTO is compact and has a minimal impact on engine packaging, while added weight is approximately 100kg.