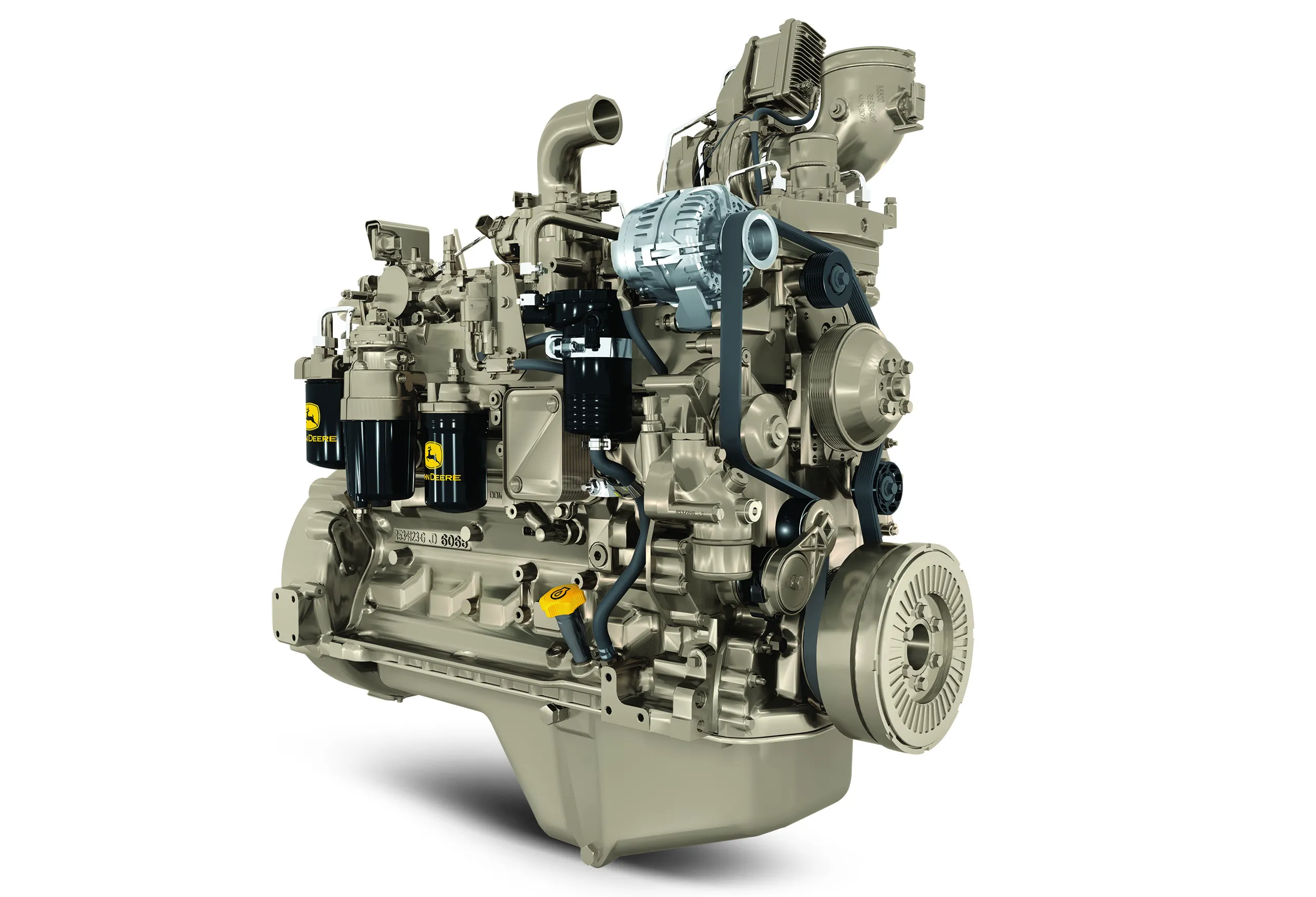

Deutz has unveiled its latest range of 2.9-16litre EU emission standard diesel engines. The TCD 2.9 L4 is available in either naturally aspirated or turbocharged versions, each with the optional extra of an intercooler. It features cooled external exhaust-gas recirculation and common-rail high-pressure fuel injection. Generating up to 55.4KW, the TCD 2.9 L4's maximum torque of 255Nm is up to 15% higher than comparable Tier 3 engines.

April 20, 2012

Read time: 2 mins

The TCD 2.9 L4 is available in either naturally aspirated or turbocharged versions, each with the optional extra of an intercooler. It features cooled external exhaust-gas recirculation and common-rail high-pressure fuel injection. Generating up to 55.4KW, the TCD 2.9 L4's maximum torque of 255Nm is up to 15% higher than comparable Tier 3 engines.

Meanwhile, the TCD 3.6 L4, a water-cooled four-cylinder engine, comes with a turbocharger and common-rail system, generating 90KW and torque of up to 480Nm. Also available with optional intercooler, it clocks up 500 operating hours between oil changes, with its maintenancefree valve train and compact EAT system reducing, according to Deutz, maintenance costs.

The water-cooled TCD 6.1 L6 is a six-cylinder turbocharged engine with intercooler and peak torque of 1.171Nm. Although featuring the same peak torque as the TCD 6.1 L6, the water-cooled TTCD 6.1 L6 comes with a straight six, twin turbo engine with a peak output of up to 203KW.

Another new engine model is the water-cooled six-cylinder TTCD 7.8 L6. This twin turbo engine comes equipped with intercooler, cooled external exhaust-gas recycling, plus Deutz Common- Rail high-pressure fuel injection.

Finally, generating up to 390KW and a torque of 520Nm, Deutz has produced the compact yet powerful TCD 12.0 V6. The watercooled engine is turbocharged and features an intercooler.