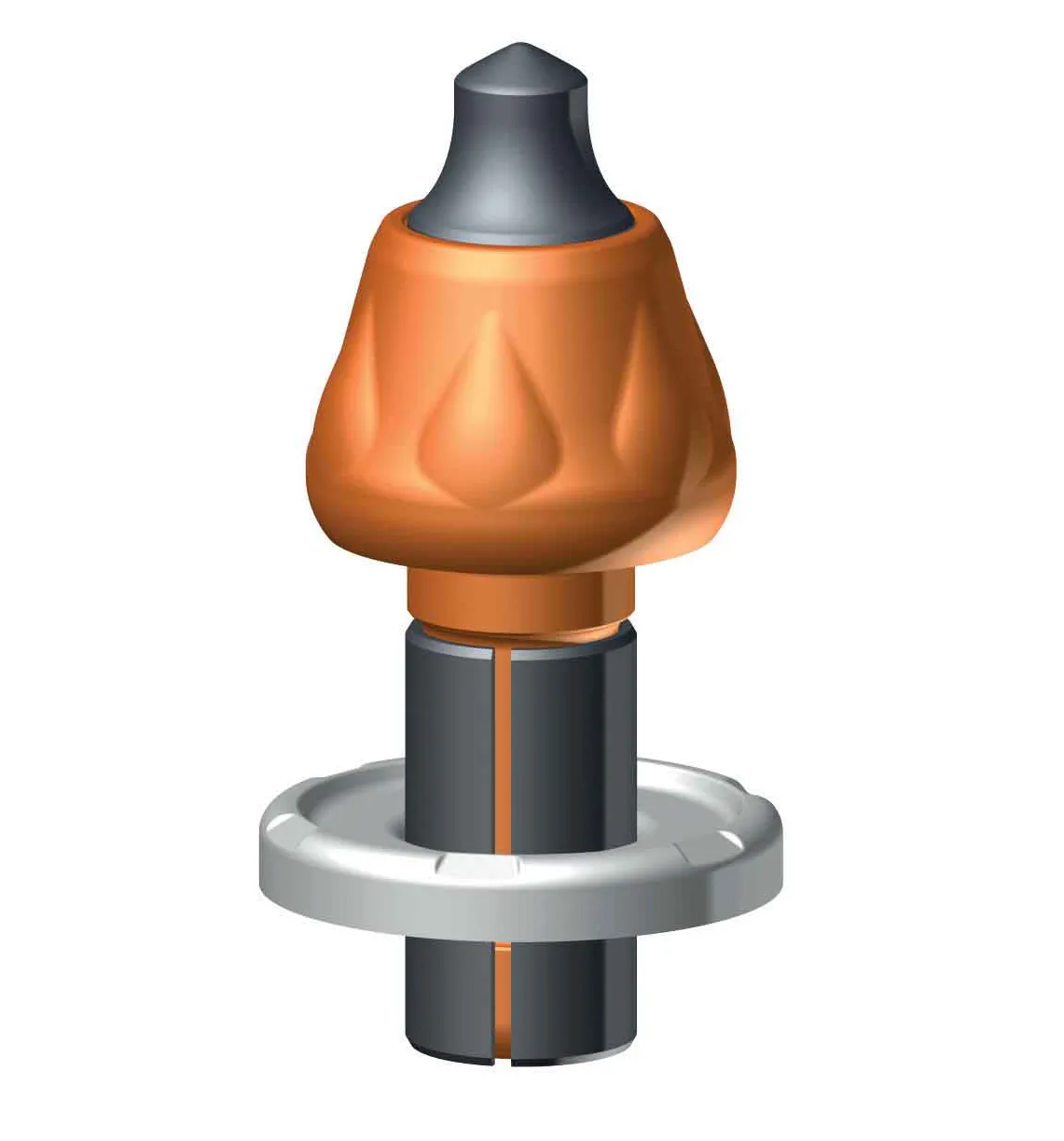

Kennametal has introduced new retainers for its line of TSC step-shank tools used on large-track trenchers. The new retainers, designated TR3, have a patented design that enables them to be installed and removed easily and quickly. The flush style of the TR3 also employs three tabs, or 'ears' that are twice as thick as previous designs, ensuring a more secure fit into the block and contributing to the speedy installation and removal. Steve Lantz, Kennametal's trenching accounts manager, said: "These retaine

July 16, 2012

Read time: 2 mins

The flush style of the TR3 also employs three tabs, or 'ears' that are twice as thick as previous designs, ensuring a more secure fit into the block and contributing to the speedy installation and removal.

Steve Lantz, Kennametal's trenching accounts manager, said: "These retainers are for the massive track trenching machines doing big projects. The operators of these machines want their tools to stay in place for as long as possible, and when they do need to be changed, they want to do it quickly to minimise downtime. The TR3 retainers address those requests from the field."

Applications for the TSC step shank tools, for which the TR3 retainers are designed, range from soft cutting to heavy-duty

rock cutting.