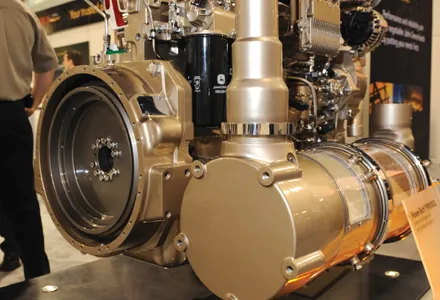

John Deere Power Systems says that its new PowerTech 13.5litre engine meets the Tier 4 Interim/Stage IIIB emissions legislation, along with the firm's latest 6.8litre and 9litre variants launched earlier.

February 21, 2012

Read time: 1 min

Meanwhile the company has also developed a new JDLink telematics system available with the latest electronically controlled Tier 4 Interim/Stage IIIB off-highway diesel engines. The system features the latest generation of JDLink equipment monitoring and the new Service ADVISOR Remote program. These tools allow customers to monitor conditions and status of engines remotely, while also allowing technicians to perform engine diagnostics and some repairs.