Specialist materials company, Element Six, hopes to boost worldwide sales for its high performance tungsten carbide tools. The firm has been manufacturing road planing picks for over 20 years and has proven its products in Europe but is looking to develop its worldwide profile. Well-proven in the European market, the company’s MasterGrade range is increasingly used by road contractors globally. The MasterGrade product is said to feature a high quality tungsten carbide grade, which the firm claims can delive

April 5, 2012

Read time: 2 mins

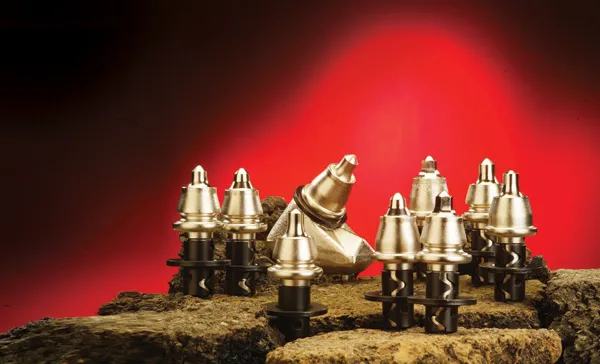

RSSSpecialist materials company, 704 Element Six, hopes to boost worldwide sales for its high performance tungsten carbide tools. The firm has been manufacturing road planing picks for over 20 years and has proven its products in Europe but is looking to develop its worldwide profile. Well-proven in the European market, the company’s MasterGrade range is increasingly used by road contractors globally. The MasterGrade product is said to feature a high quality tungsten carbide grade, which the firm claims can deliver tool life gains of up to 50% over some competing products.

Element Six applies proprietary nano technology to improve the Cobalt binder matrix of the Tungsten Carbide inserts used on its road picks. The firm says that by doing so, greater wear resistance and a better fracture toughness is achieved. In addition to the extended tool life of up to 50%, the firm says its picks can reduce operating costs, improve productivity and cut downtime. Because the tools last longer the change-out periods are extended so contractors are able to keep a mill running for an increased number of operating hours. The high quality picks are also said to allow high performance milling, resulting in a smooth finished surface.

Element Six applies proprietary nano technology to improve the Cobalt binder matrix of the Tungsten Carbide inserts used on its road picks. The firm says that by doing so, greater wear resistance and a better fracture toughness is achieved. In addition to the extended tool life of up to 50%, the firm says its picks can reduce operating costs, improve productivity and cut downtime. Because the tools last longer the change-out periods are extended so contractors are able to keep a mill running for an increased number of operating hours. The high quality picks are also said to allow high performance milling, resulting in a smooth finished surface.