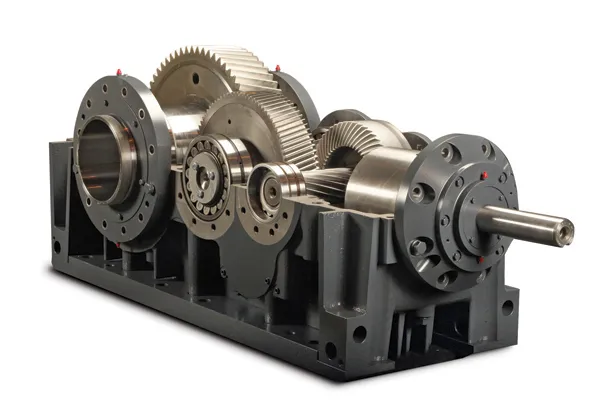

Rexnord Industries claims that its new Falk V-Class gear drives are designed for maximum uptime and durable performance. The Falk V-Class features advances in materials technology, engineering design, and manufacturing processes to produce a tough, reliable gearbox. Other features include innovative mounting and cooling accessories, delivering maximum uptime in a smaller drive at a lower total cost of ownership.

February 29, 2012

Read time: 1 min

The Falk V-Class features advances in materials technology, engineering design, and manufacturing processes to produce a tough, reliable gearbox. Other features include innovative mounting and cooling accessories, delivering maximum uptime in a smaller drive at a lower total cost of ownership. These novel drives suit duties in conveyor applications, have a good thermal performance and can withstand tough environments. The heavyduty, horizontally split housing design incorporates advanced gearing for high performance under load. Additional features increase productivity and profitability such as no-leak seals with oil drain backs and purgeable grease chambers to eliminate oil leaks. An optional, cooling system requires no water or electricity to operate.