The innovative F5, NEF and Cursor Series engines all feature the latest technologies such as common rail fuel delivery, electronic unit injectors and variable geometric turbochargers.

The F5 Series is based around a four-cylinder, 3.2litre architecture and can be tailored to specific requirements, while offering low fuel consumption and reduced maintenance needs. This compact design suits installations in machines such as skid steer loaders and small backhoe loaders.

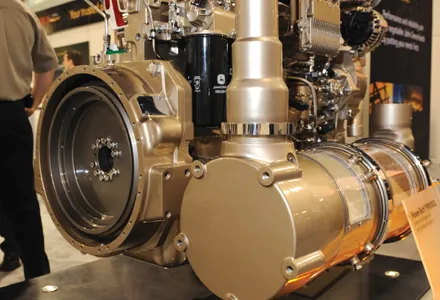

Moving up in scale, the NEF Series is offered in four or six-cylinder variants of 3.9, 4.5, 6 and 6.7litre capacity. This series is available in both mechanical versions and with electronic common rail fuel systems. The wide range of options is said to allow the engines to be installed in differing applications such as small excavators, wheeled loaders and generators.

FPT Industrial is promoting its new N67 Tier 3 engine, which is designed to meet the needs of the Chinese market. Delivering power outputs of 74-200 kW, this 6.7litre engine is based on FPT Industrial’s sophisticated Tier 4 Final technology.

The firm’s Cursor Series is for six-cylinder engines of 9 or 13litres, with features including high power and torque outputs and fast throttle response, as well as low fuel consumption and operating costs.