Element Six claims construction tool life is increased by 34% through use of its new HardZone synthetic diamond encapsulation technology. According to the company, the HardZone process can be used by tool manufacturers to either extend tool life or increase productivity, and is said to have been designed for easy adoption by tool manufacturers.

June 20, 2012

Read time: 2 mins

According to the company, the HardZone process can be used by tool manufacturers to either extend tool life or increase productivity, and is said to have been designed for easy adoption by tool manufacturers.

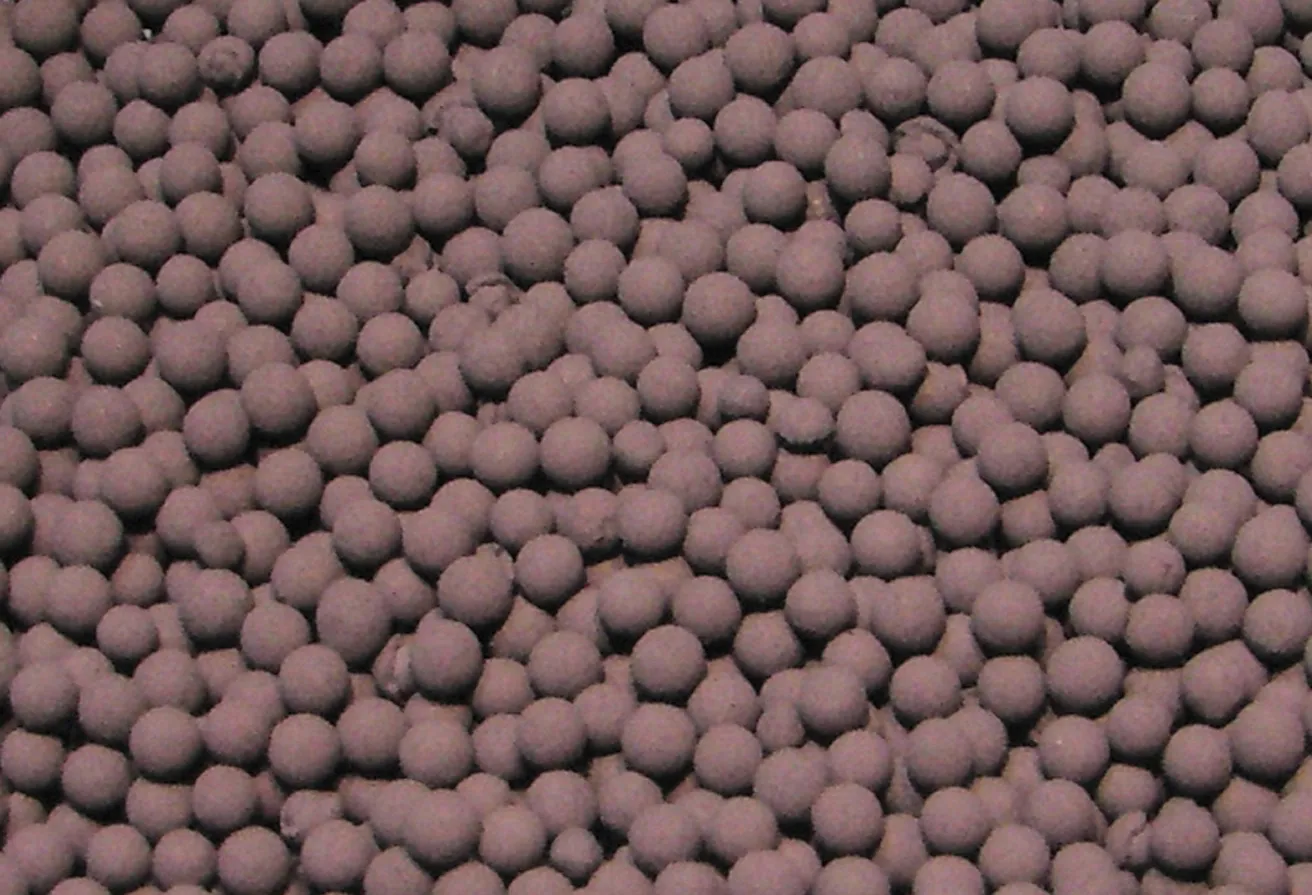

Encapsulation of synthetic diamond is said by Element Six to be the process of building up metal bond material around the synthetic diamond particle to the extent that the particle is completely enveloped by a sufficient quantity of bond powder to produce a sintered cutting segment.

"We have taken encapsulation to a new level with the addition of HardZone technology. It incorporates a bond material with a better wear resistance as a first layer directly surrounding the synthetic diamond, with a subsequently applied outer layer of standard metal bond material," explains Dr David Egan, senior metallurgist at Element Six. "The purpose of this is to improve the tool’s wear resistance and enable higher synthetic diamond protrusion, as well as providing the expected uniform synthetic diamond distribution," added Egan. The claimed 34% rise in construction tool longevity is said to be based on concrete cutting tests compared to standard mixed particle blades.