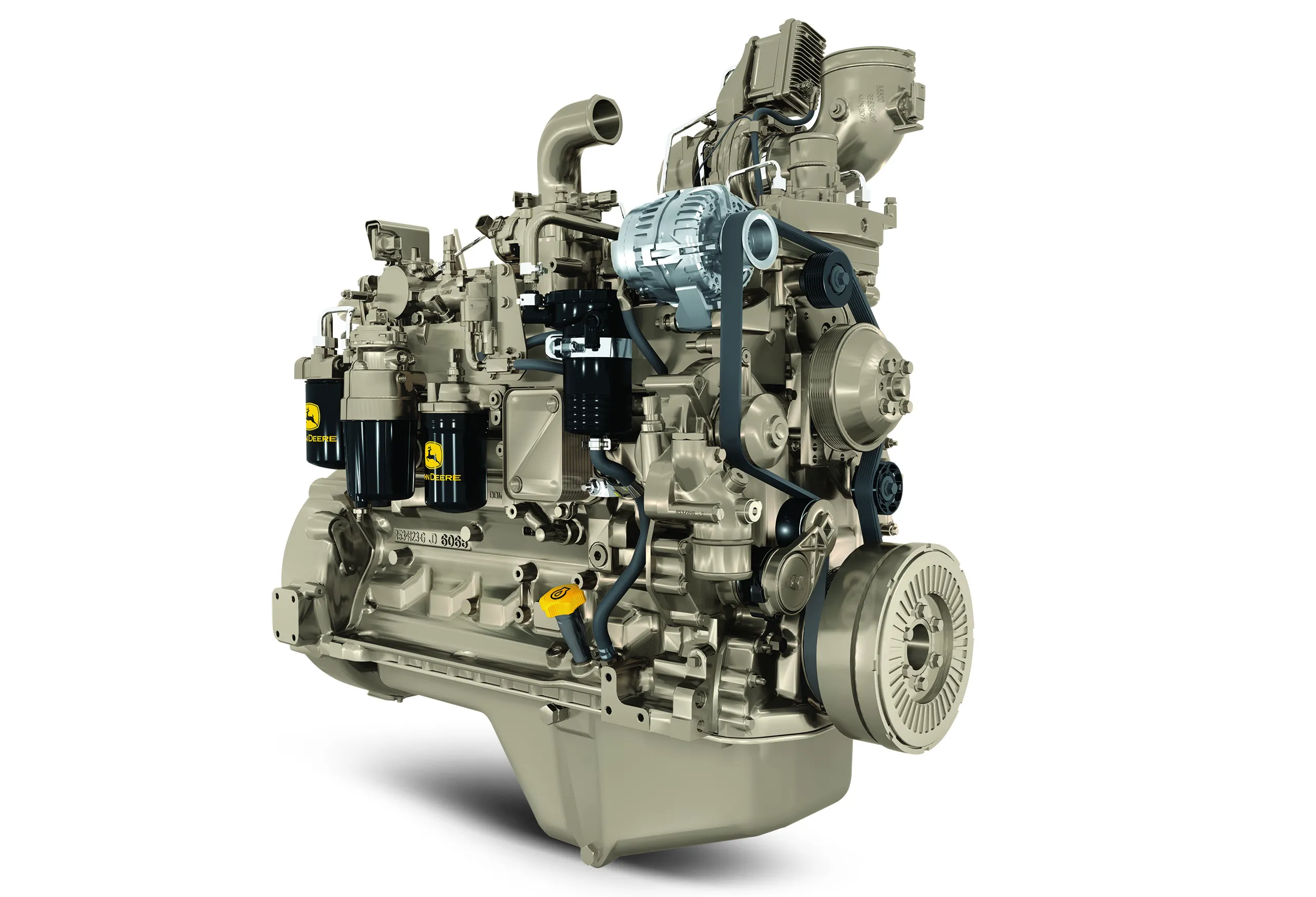

TCD 5.0 is the name given to the latest engine from

Key engine developments for the TCD 5.0 include an overhead camshaft design with maintenance-free hydraulic tappets. Deutz said that this development offers scope for variable valve timing in the future, along with improved thermodynamics and better heat management for exhaust after-treatment packages.

The company said the TCD 5.0 is an option for those seeking to substitute a larger engine without a sacrifice in power - or it can offer a performance increase for existing engines of the same physical size.

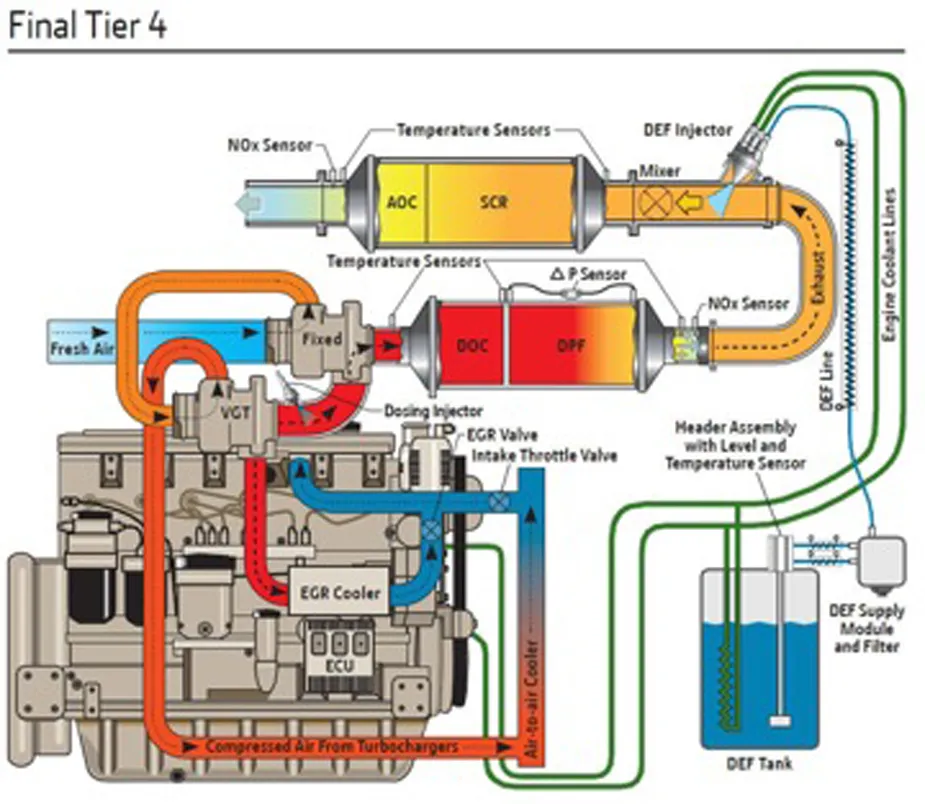

Using a single turbocharger and charge-air cooling, this latest addition to the TCD engine portfolio uses cooled EGR along with DOC, DPF and SCR to meet Stage V emissions regulations. However, integration of the EGR mechanism as part of the engine block makes the engine easily adapted – using blanking plates and software upgrades - to less stringent markets.

Deutz said a higher power version of the TCD 5.0 will follow.