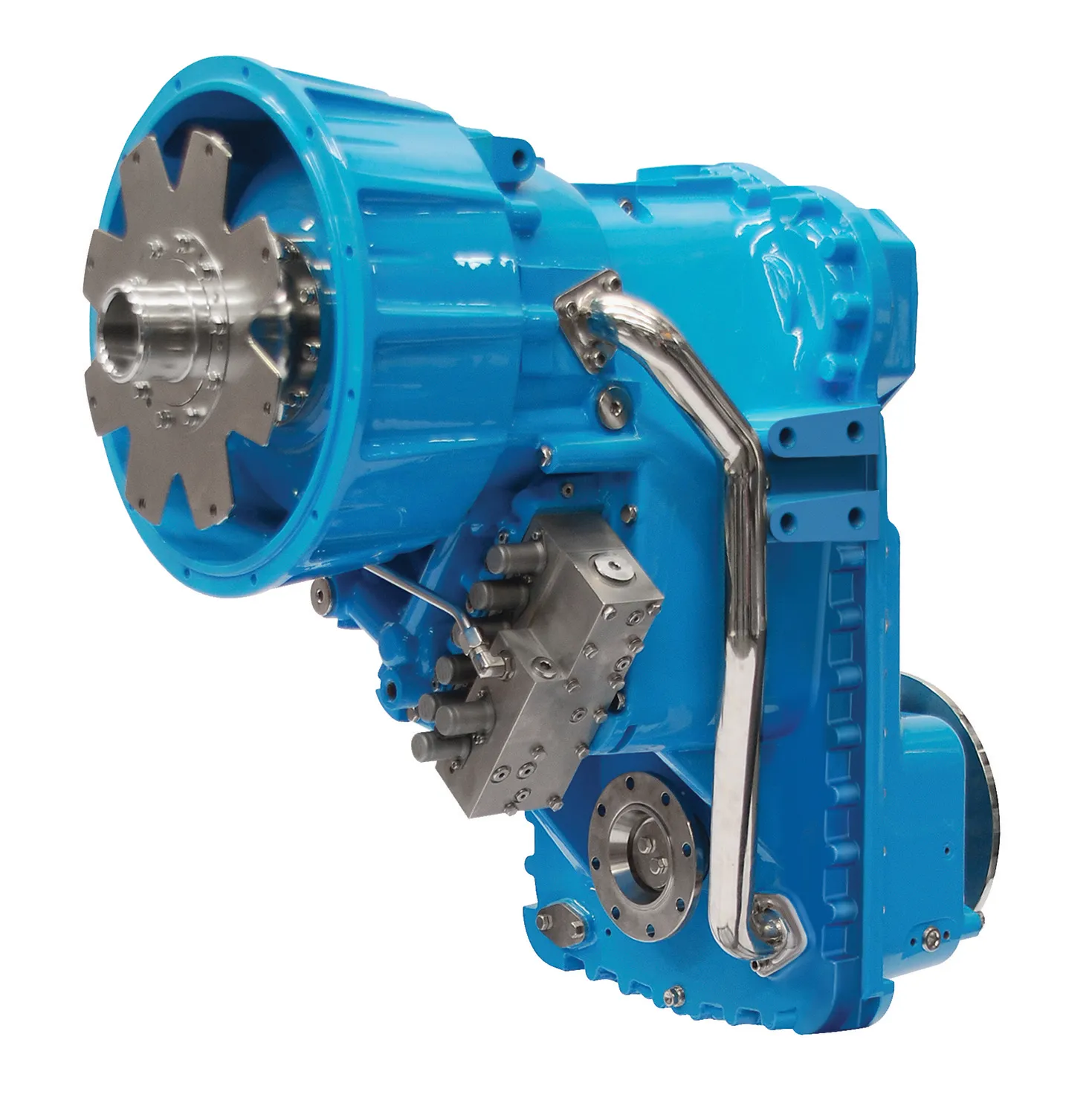

Dana Holding Corporation has started production of its Spicer TZL Series, a new line of powershift transmissions for premium front-end loaders manufactured in China. The Spicer TZL16 transmission has been engineered for 17tonne ZL50 front-end loaders, which account for about two-thirds of the front-end loaders manufactured in China.

June 15, 2012

Read time: 2 mins

The Spicer TZL16 transmission has been engineered for 17tonne ZL50 front-end loaders, which account for about two-thirds of the front-end loaders manufactured in China.

"The Chinese construction market is growing steadily, and there is an increasing number of Chinese manufacturers pursuing global expansion. Dana can best support this growth opportunity with an increased product range and in-region operational capability,” says Aziz Aghili, president of Dana Off-Highway Driveline Technologies.

First unveiled at

Dana has begun development on the next products in the TZL Series, including the Spicer TZL18 transmission for 21tonne front-end loaders and the Spicer TMG14 transmission targeted for 110-160kW (150-215 horsepower) motor graders. Production of these products is due to begin this spring.