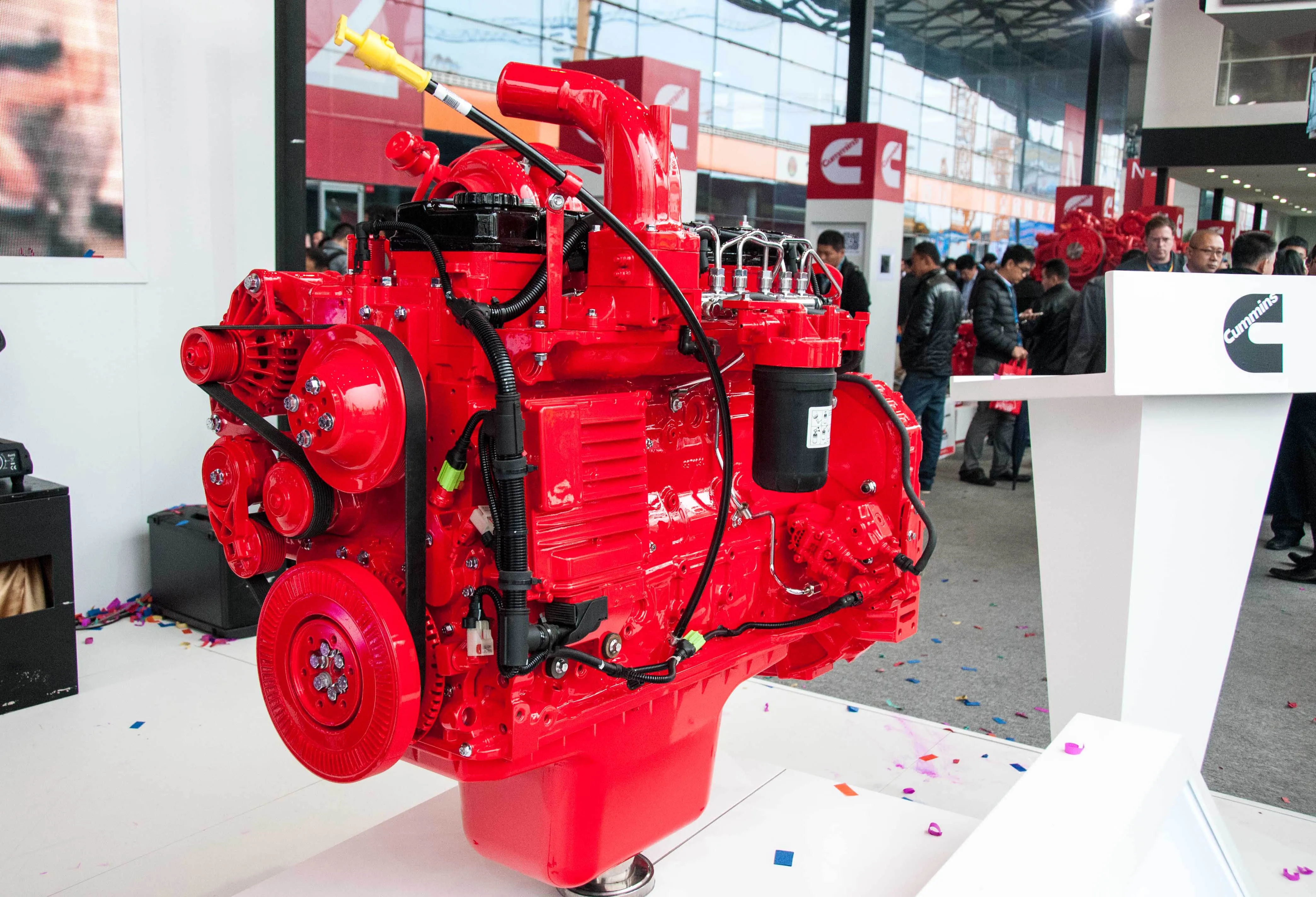

The QSF3.8 is a 3.8litre 4 cylinder diesel unit delivering 74-104kW of power with peak torque of 540Nm. Manufactured by Cummins Beijing plant it utilises a common rail high pressure fuel system. It is designed to power 10-17 tonne class excavators, 4-10 tonne forklifts, compactors, backhoe loaders and other applications.

The QSB7 is a six cylinder 7litre diesel unit with a power output of 120-160kW. Peak torque is 895Nm. It utilises a rear gear train for lower noise and has a common rail high pressure fuel system. The engines are manufactured at the Guangxi Cummins Industrial Power facility.