Cummins has signed an agreement with Terex Advance Mixer, a subsidiary of Terex Corporation, Edge Materials and PCC Hydrogen, to develop hydrogen-fuelled internal combustion engines for use in concrete mixer trucks.

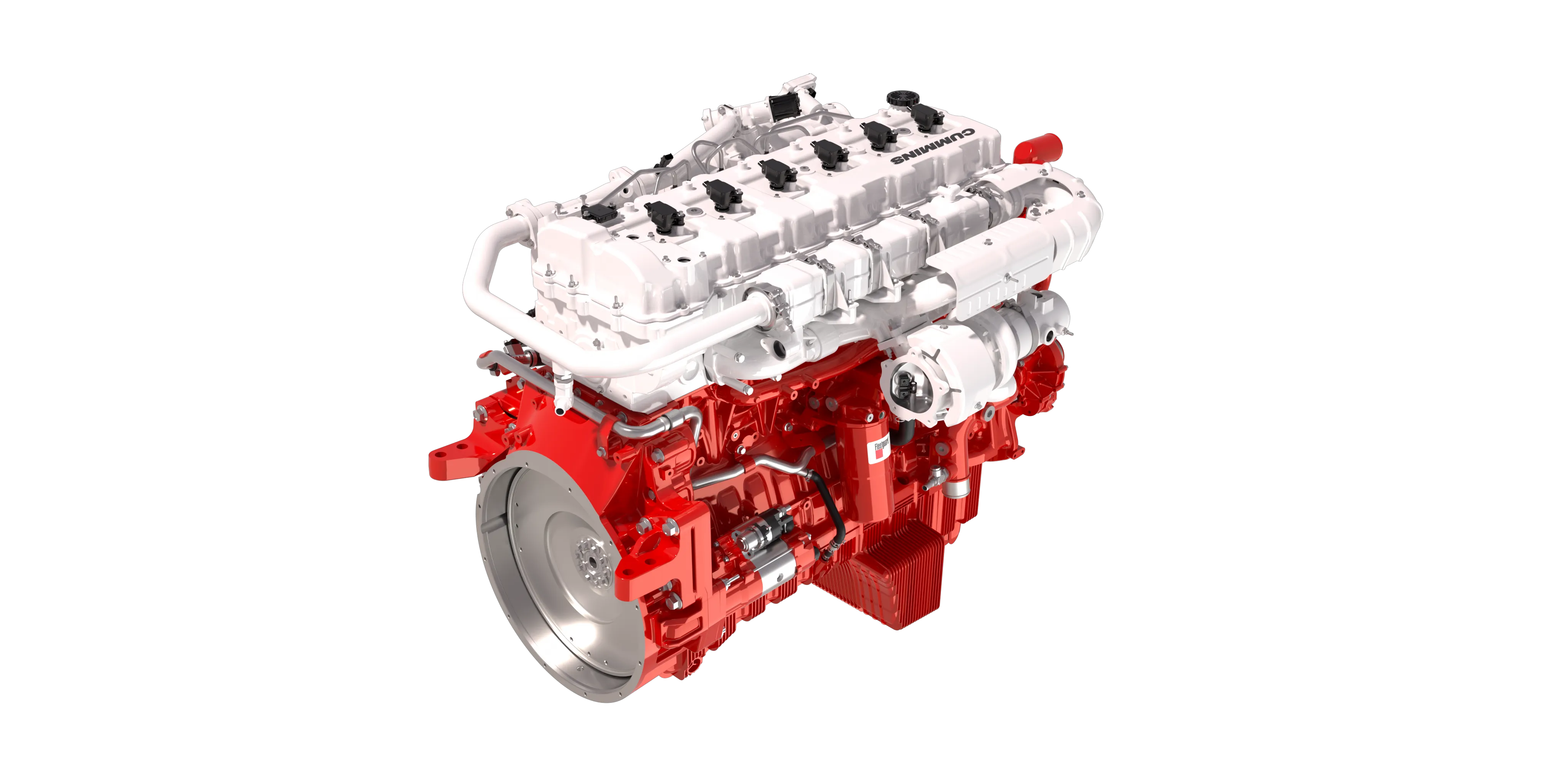

The project aims to develop a full hydrogen ecosystem with a hydrogen producer, vehicle manufacturer and end user. It is the first agreement of its kind signed by Cummins. The four companies will unite their efforts to see Cummins' X15H hydrogen internal combustion engines integrated into the Terex Advance Commander Series of front-discharge concrete mixer trucks.

Edge Materials, a ready-mix concrete provider and Terex Advance customer, will operate the hydrogen-powered trucks at operations including construction sites and infrastructure projects. PCC Hydrogen, a low carbon intensity hydrogen producer in Kentucky, will supply the hydrogen fuel, stationary storage and dispensing services.

"While Cummins is investing in a range of power options to support decarbonisation, hydrogen internal combustion engines are emerging as a key technology to eliminate carbon emissions from heavy-duty sectors while retaining the power density and operational range typical of diesel engines," said Jim Nebergall, general manager - Hydrogen Engines at Cummins.

Aligned with Destination Zero - Cummins' strategy to reduce its products' greenhouse gas and air quality impacts - the collaboration will spearhead decarbonising mixer trucks without impacting vehicle performance.

David Grabner, general manager at Terex Advance Mixer, added: "Customers expect Terex Advance concrete mixer trucks to deliver consistent and high-quality concrete efficiently and reliably while minimising environmental impact through reduced emissions and fuel consumption. Decarbonising concrete mixer trucks, however, can be difficult due to the energy demands and long operational hours. This project marks a significant milestone in our decarbonisation journey, as Cummins' X15H engines introduce an alternative, zero-carbon emissions option for our customers while providing the performance our trucks need to get the job done."

Cummins' hydrogen engines use proven internal combustion engine technology to use zero-carbon hydrogen fuel rather than traditional diesel. They are similar in architecture to today's diesel and natural gas-powered engines, offering heavier-duty, longer-range applications a route to decarbonise without major changes to vehicle designs and at a lower upfront cost than current zero-carbon alternatives.

Cummins

www.cummins.com

PCC Hydrogen

www.pcchydrogen.com

Terex

www.terex.com