Starting in the first quarter of 2024, Caterpillar will develop a transient-capable system for off-highway applications. The project will demonstrate how state-of-the-art control systems and electric-hybrid components can help hydrogen-fueled engines meet or exceed traditional diesel engines' power density and transient performance.

Caterpillar will serve as the prime contractor on the project, providing engine research and development and system integration. As the project progresses, other industry and academic collaborators will be brought into the project to provide additional expertise. The initiative will be delivered at Caterpillar facilities in Chillicothe, Ill. and San Antonio, Texas.

With research commencing in 2024, the project is supported and partially funded by the US Department of Energy’s (DOE) Vehicle Technologies Office (VTO) through the Office of Energy Efficiency and Renewable Energy (EERE). It is included among 45 projects across 18 states and Washington, DC, receiving funding to advance research, development, demonstration, and deployment in several areas critical to reducing greenhouse gas (GHG) emissions in the transportation sector.

The hydrogen-hybrid power demonstration project is the latest in a series of initiatives built upon Caterpillar’s 35 years of enterprise experience in hydrogen fuels.

“Every off-highway application has its own unique duty cycles, lifecycle demands and performance expectations, and this complexity is driving the development of a wide range of power solutions for the energy transition,” said Steve Ferguson, senior vice president of Caterpillar Industrial Power Systems. “One size does not fit all, which is why we’ve engineered flexibility into the C13D engine to serve as our platform of the future.

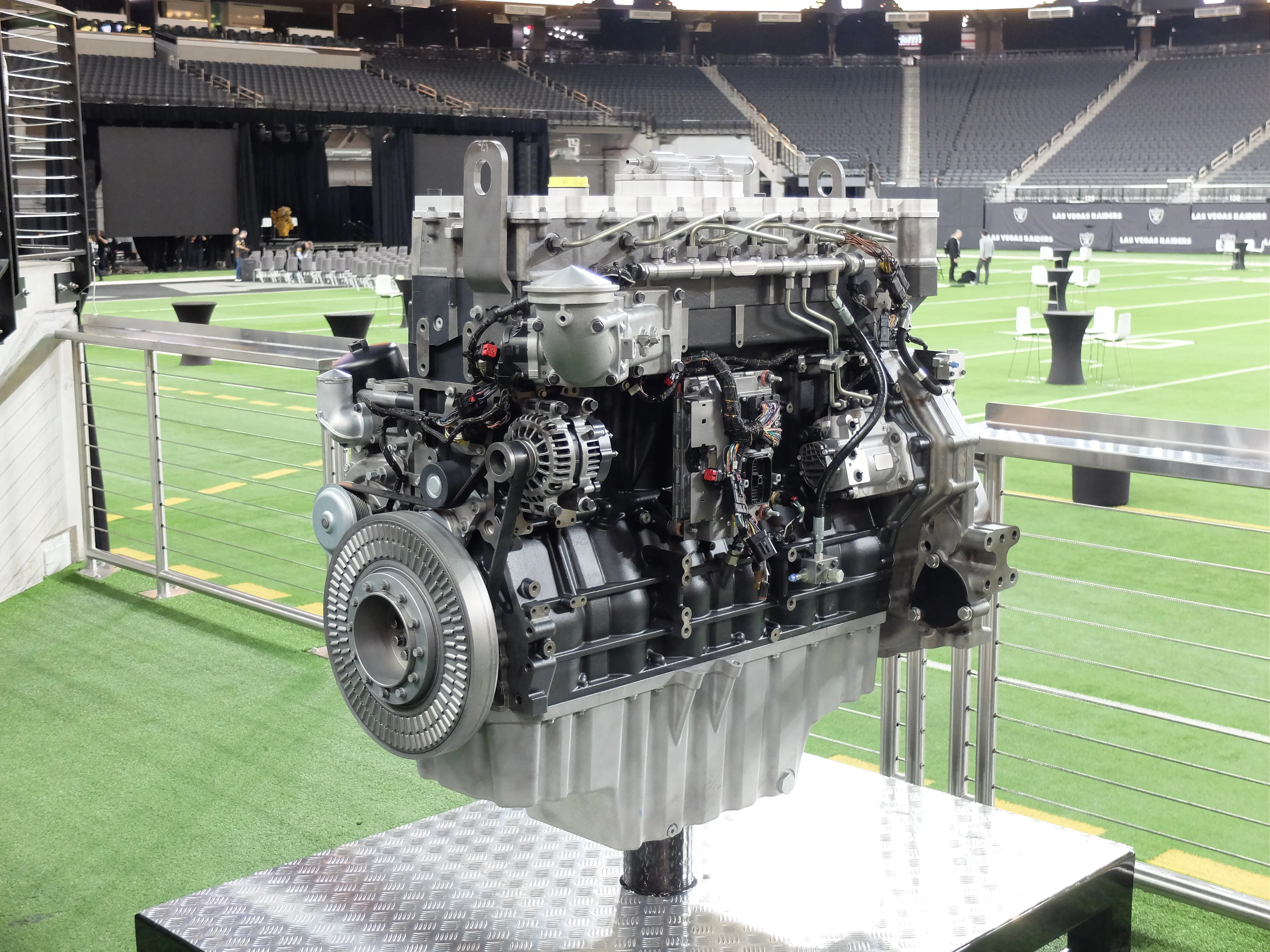

Caterpillar’s hydrogen-hybrid demonstration project leverages the performance, packaging, and fuel flexibility engineered into the new 13litre Cat C13D engine platform.

Diesel-powered versions of the Cat C13D engine offer eight power ratings from 340-515kW with up to 3,200Nm of peak torque. It provides up to a 20% increase in power and up to 25% more low-speed torque than the previous generation of Cat diesel engines in its power class.

The inline, six-cylinder Cat C13D enables the use of renewable liquid fuels such as 100% HVO, B100 Distilled Biodiesel, and even up to B100 Standard Biodiesel by working with the local Cat dealer. In addition to using hydrogen, its core architecture is designed for the future development of spark-ignited natural gas capabilities.

Available for early OEM pilots in 2025 and scheduled for production in 2026, the Cat C13D engine is targeted for a wide range of off-highway equipment, including rock crushers, screeners, and grinders; and large industrial pumps.