Diesel engine producer Perkins has now opened its research facility, an operation in which the firm has invested some €21.2 million (£19 million).

March 1, 2012

Read time: 1 min

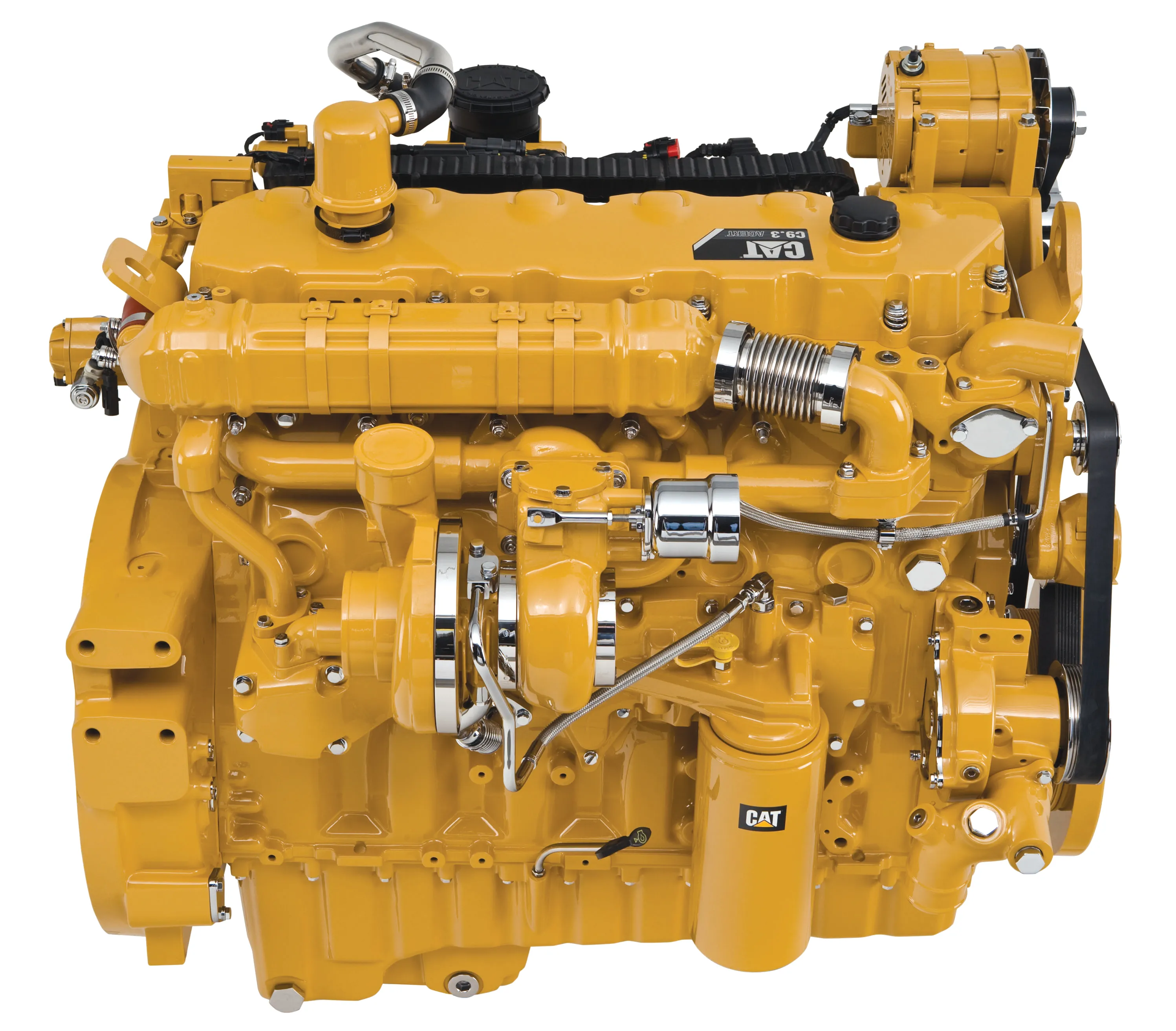

Diesel engine producer 299 Perkins has now opened its research facility, an operation in which the firm has invested some €21.2 million (£19 million). In the last three years Perkins has installed 12 new validation cells, a tilt cell and upgraded a further five cells at its Global Engine Development centre (GED). The facility allows Perkins to put its latest Tier 4 engines through stringent validation tests. This develpment follows on from the company's investment in a crankshaft machining centre at Peterborough, which opened in November 2009. As a result of the investment, GED has approximately 50 test cells and additional specialist cells undertaking a variety of complex validation tests, including performance and emissions, mechanical development, endurance and transient development.