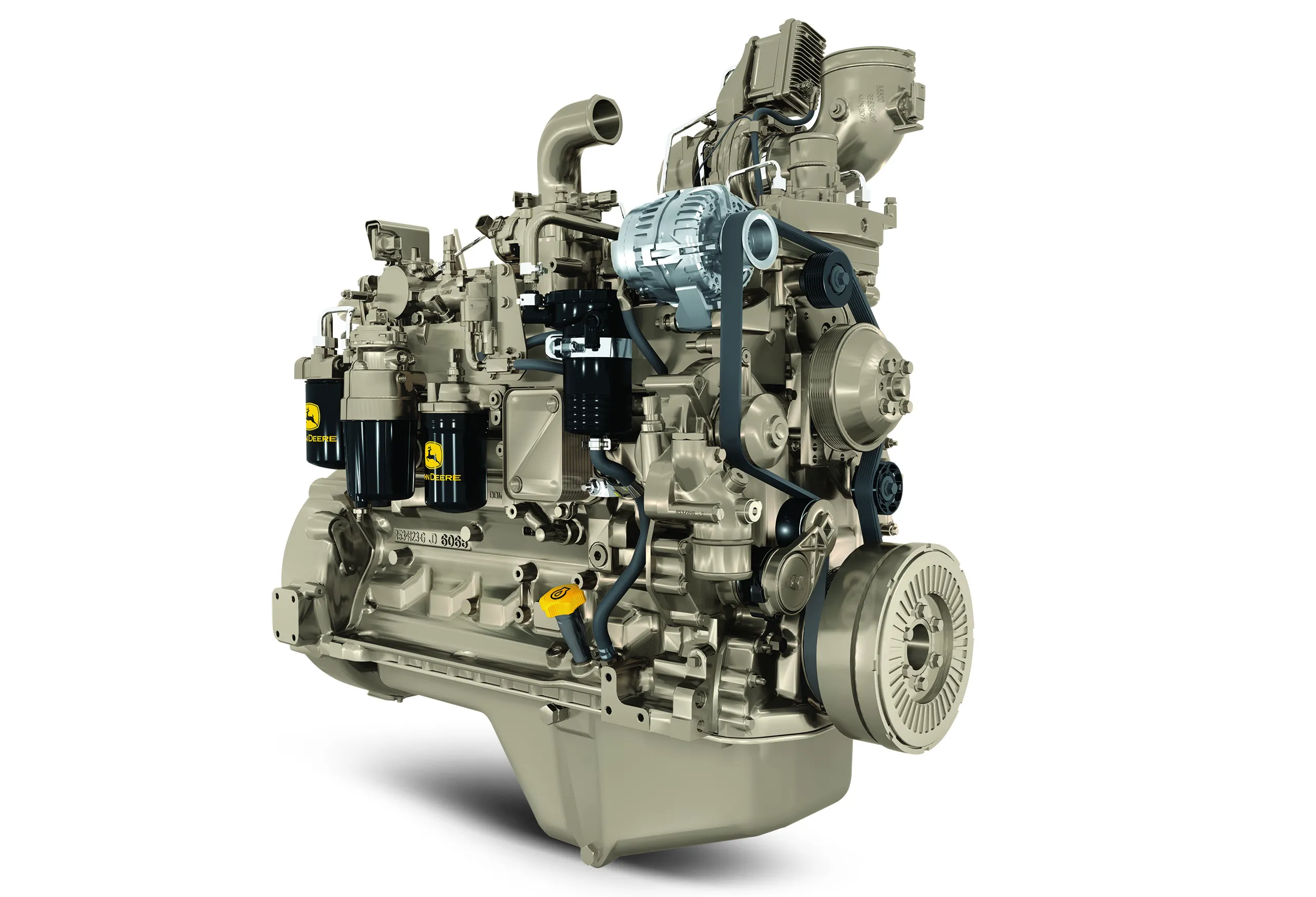

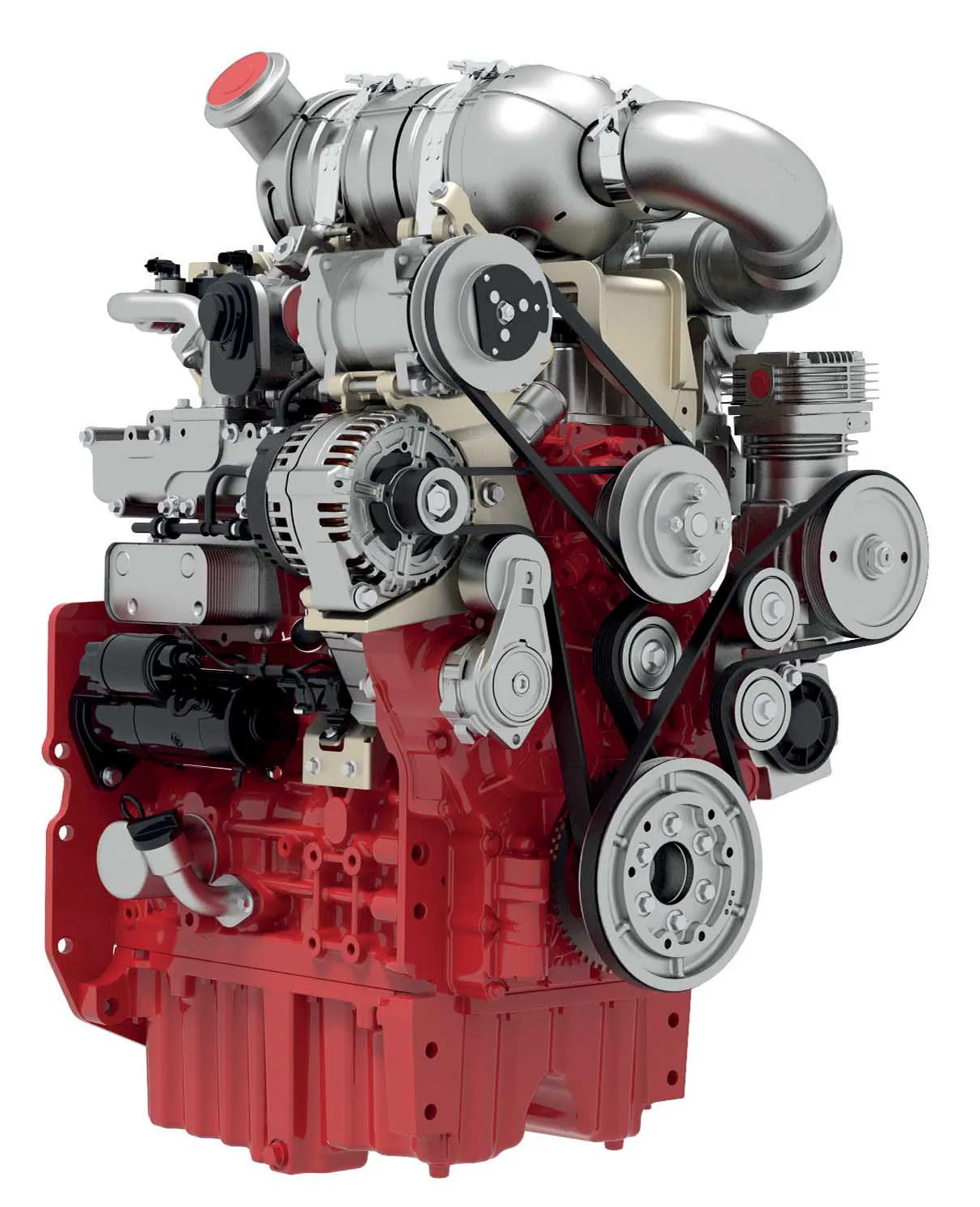

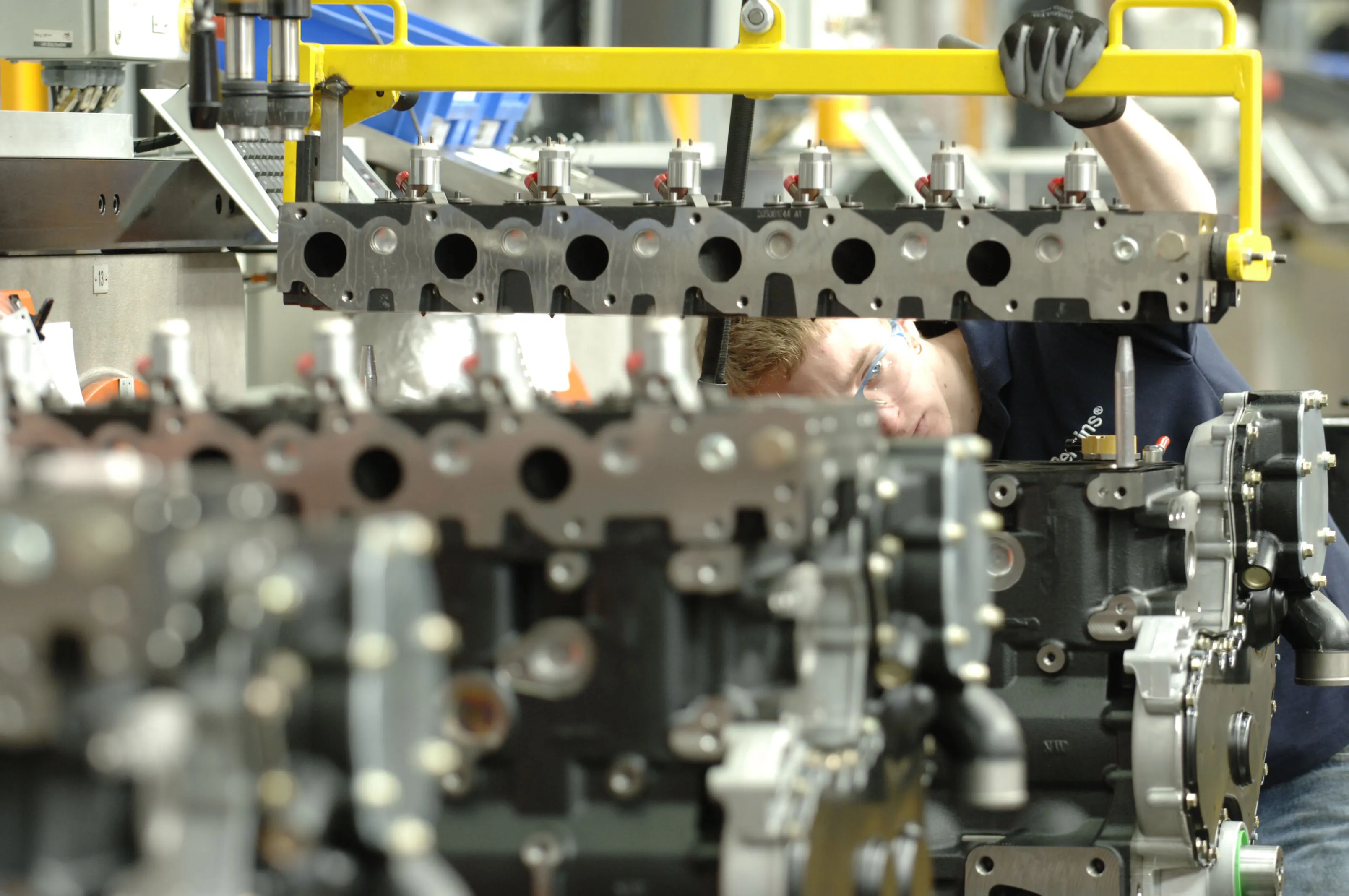

There are 15 basic engine models in the line-up, with a huge range of variants to suit a massive array of different applications and installation requirements. Power outputs range from 8.8-10.2kW for the diminutive, two cylinder 402J-05 with its 0.5litre capacity right up to the six cylinder 28063-18, with a capacity of 18.1litres and power outputs from 423-470kW.

Perkins is using technologies that include common rail fuel systems, diesel exhaust fluid (DEF), selective catalytic reduction (SCR), diesel oxidation catalysts (DOC) and diesel particulate filters (DPF). The systems used in these engines to deliver the ultra-low emissions performance varies, depending on the size. The two smallest units in the 400 Series are only offered in naturally aspirated versions so are much simpler, while the largest engines have turbochargers and after-cooling and are more complex. Those engines with power outputs of 56kW and over feature DOC and DPF, as well as DEF and SCR after-treatment systems.

The Stage V regulations come into force from January 2020 for engines with power outputs in the 56-560kW range and from January 2019 in Europe for all other power classes. The reduction in emissions is substantial. For a Stage V engine with a power output of 75kW, it will produce just 0.015 g/kW.hr of particulates, a 120th of the quantity generated by a non-regulated engine.

The company’s low cost engine monitoring system is called the SmartCap meanwhile and offers a simple and straightforward solution aimed at use with small items of rental equipment. This novel connectivity device can be used with both mechanical and electronic engines and is an oil filler cap that features a small circuit and battery located inside. The electronic circuit in the SmartCap can be used to monitor engine hours and can be linked to a smartphone through