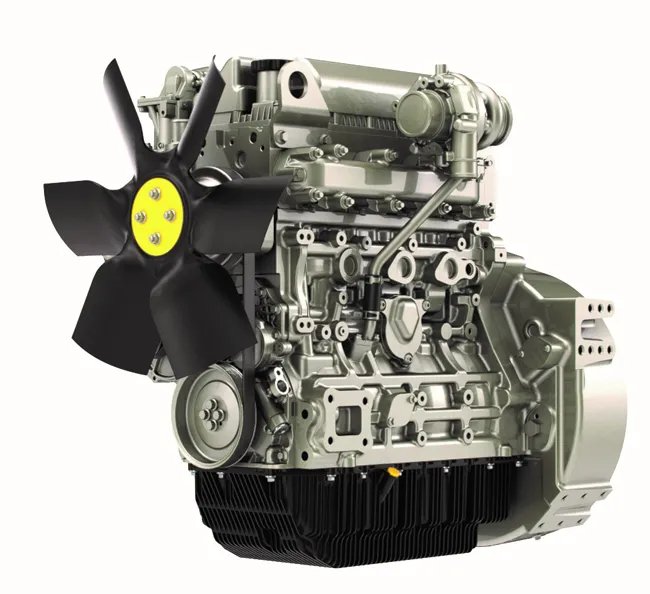

Perkins is introducing its new 3.6litre Syncro diesel to the Chinese market. The engine is a fou-cylinder unit, with a 3.6litre capacity and is the newest addition to the model range. This engine produces 100kW and up to 500Nm of torque. Key features include a combination of low operating noise levels with a fast responding smart turbocharger. This allows the new diesel to achieve the high power density needed to allow it to take the place of larger engines in many compact and mid-size equipment application

November 21, 2018

Read time: 2 mins

“Perkins is globally prepared with the Perkins Syncro 3.6litre engine,” said David Nicoll, director of Marketing & Dealer Operations. “Our engine is modular, which enables original equipment manufacturers (OEMs) to meet all global emissions standards from one core platform, including US Tier 4 Final, EU Stage V, Tier 3 for lesser regulated areas, and beyond. This enables OEMs to design their machine once, for multiple territories, saving valuable development expense.”

He added, “It’s also designed for OEMs with tough applications in mind – and it allows them to downsize their machine’s engine space at the same time, adding efficiency. Taking advantage of electronic turbocharging ensures the Perkins Syncro 3.6litre responds faster when the operator requires extra power and torque on the job site.”