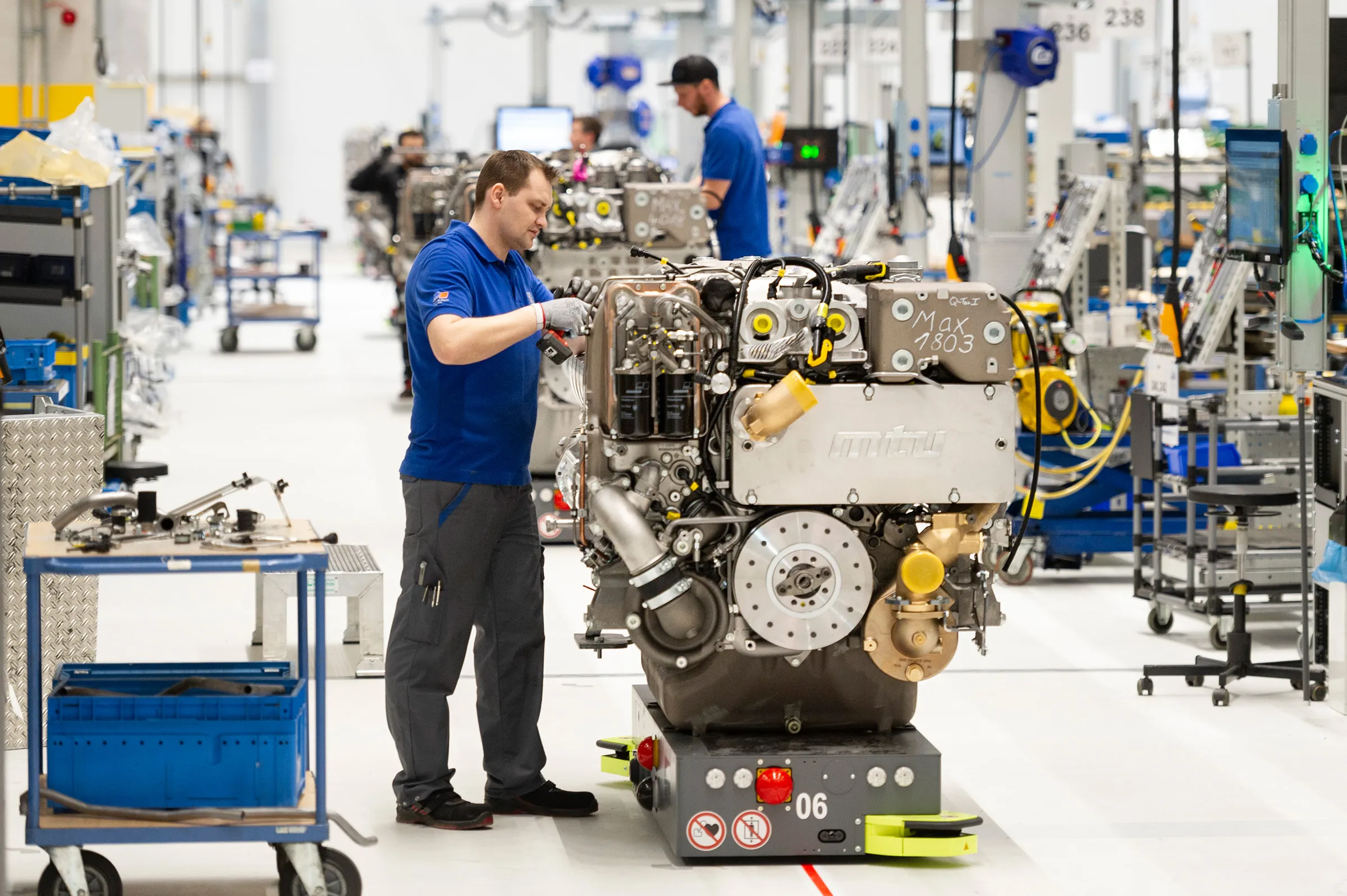

Rolls-Royce is opening its new €30 million facility in Germany making mtu engines. The new combustion engine assembly plant is a production facility for the mtu 2000 series engines. It is located in Kluftern on Lake Constance, Germany.

This investment highlights future prospects for internal combustion engines in the energy transition through the use of sustainable fuels. The new production facility, which was announced in 2021 provides space for assembly and shipping. The assembly of mtu Series 2000 engines will be relocated to Kluftern, enabling the modernisation of the existing assembly halls in RollsRoyce’s Plant 2 in Friedrichshafen, which will provide long-term production space for the Series 4000 engine. The Kluftern plant currently employs 110 people.

The new production building has been designed to be highly energy-efficient and climate-friendly. For example, a 1.2 MW-peak photovoltaic system provides green electricity, e-charging columns ensure clean mobility solutions, and an intelligent building control system alongside other equipment measures will ensure energyefficient operation.

Dr Jörg Stratmann, CEO, Rolls-Royce Power Systems, said: “Our investments are a clear commitment to the region and to our products and solutions, which are important building blocks of the energy transition in various application areas. We are convinced that, in conjunction with sustainable fuels and new technologies, the internal combustion engine will play a central role in the future. Because it's the fuel that matters, not the engine.”

Rolls-Royce is developing engines that can run on a wide range of sustainable fuels, replacing fossil fuels and significantly reducing carbon dioxide emissions. This will enable the firm to provide climate-friendly propulsion technologies in the future for applications to energy systems where complete electrification is not an optimal solution in the long-term.

Renewable diesel (HVO/hydrogenated vegetable oil) is an important step on the road to decarbonisation. Many mtu engines from Rolls-Royce have already been released for use with this sustainable fuel. HVO enables up to 90% CO2 reduction as well as reducing particulate and nitrogen oxide emissions. It can be produced on an industrial scale from hydrogenated vegetable oil and waste materials from the catering and food industries.

Dr Stratmann explained: "We are doing everything we can to make the internal combustion engine climate-neutral with sustainable fuels and in combination with new technologies. But this can only be achieved if the political framework conditions are set so that alternative fuels can be successfully ramped up."