The Marangoni Group has announced it will invest €8 million to modernise its plant in the northern Italian city of Rovereto, near Trentino.

The upgrade includes the latest generation of Banbury mixer capable of meeting demand for increasingly sophisticated and high-performance compounds. The mixer, to be in operation by the end of the year, will improve the quality of earthmoving tread compounds, making them more competitive for heavy-duty applications.

Another important investment made in recent mont

April 10, 2015

Read time: 2 mins

The 7933 Marangoni Group has announced it will invest €8 million to modernise its plant in the northern Italian city of Rovereto, near Trentino.

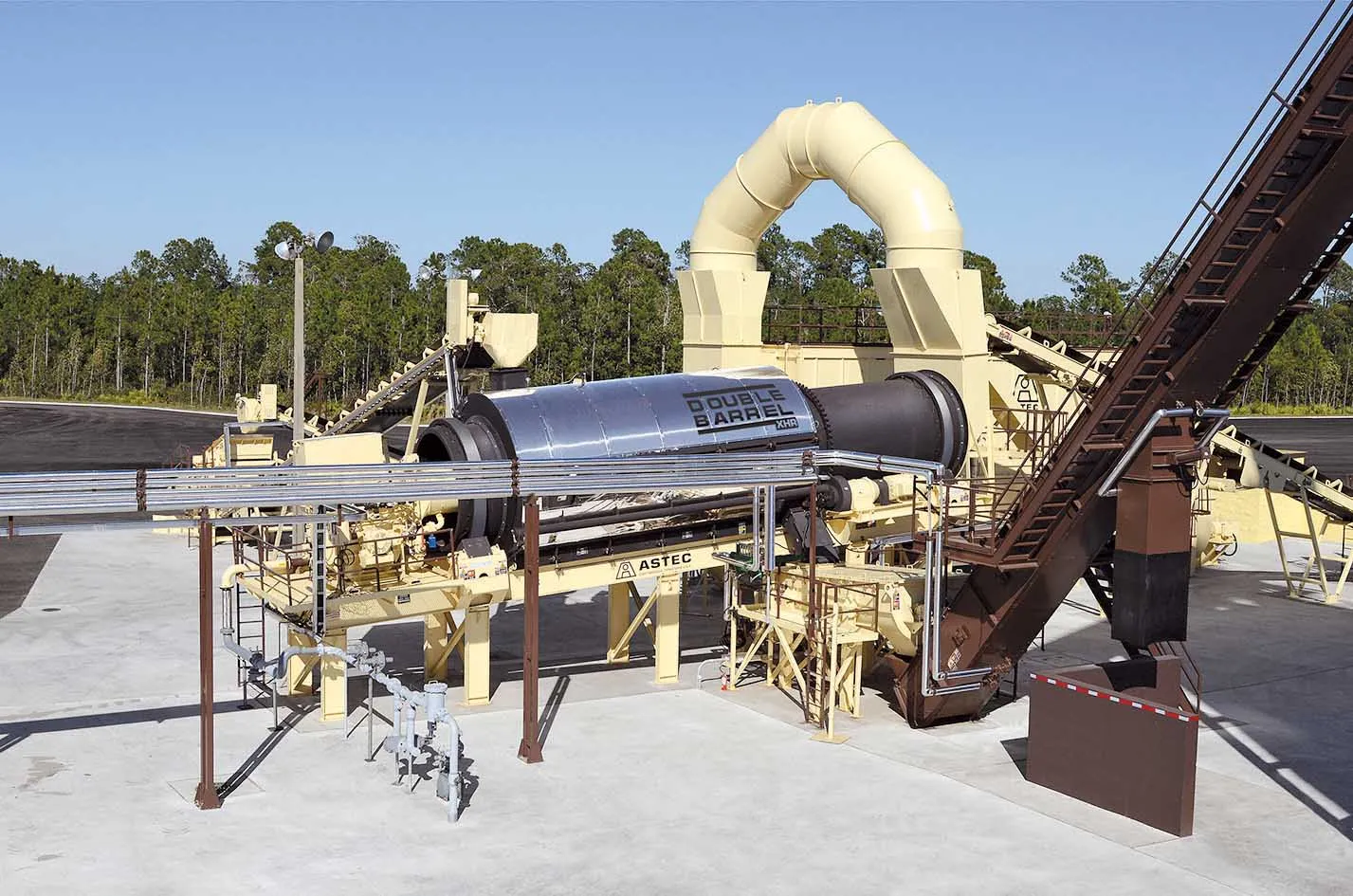

The upgrade includes the latest generation of Banbury mixer capable of meeting demand for increasingly sophisticated and high-performance compounds. The mixer, to be in operation by the end of the year, will improve the quality of earthmoving tread compounds, making them more competitive for heavy-duty applications.

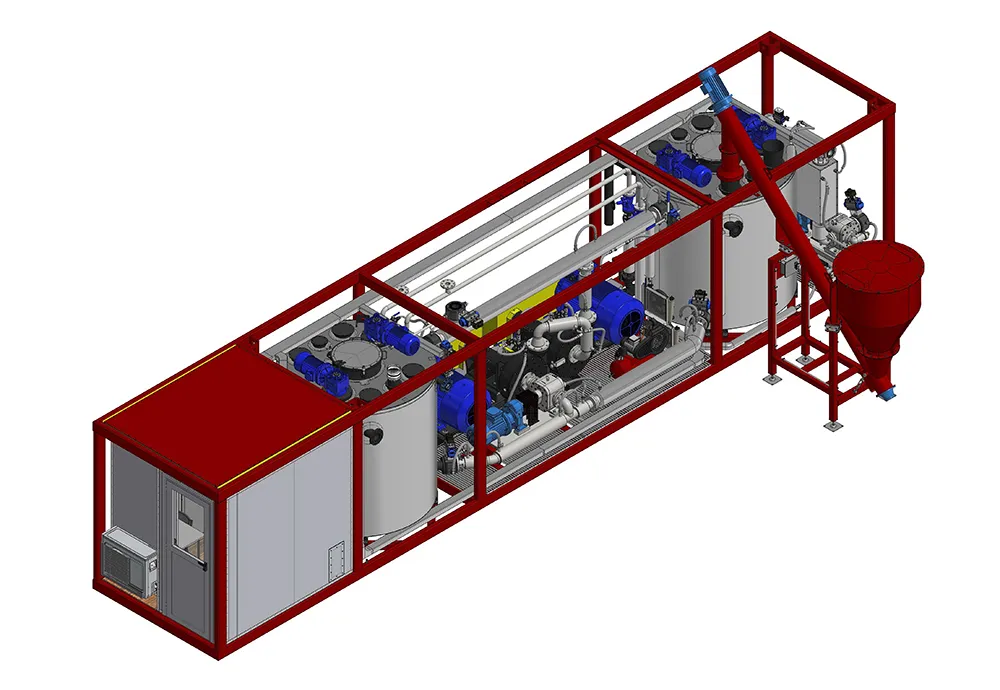

Another important investment made in recent months concerns the building of hot-cure retreads in a production ‘island’. The manages the entire tyre retreading process, fully automatically and flexibly.

Other upgrades are being made to the vulcanisation department, with the purchase of presses that can house 12 sector cylindrical moulds. These will further improve product uniformity by reducing the relatively frequent phenomena of ovalisation and unbalance when retreading a used tyre.

“I’m more and more convinced that there will be many opportunities for quality retreads in the future, and this is the focus of the efforts we are making to improve processes and increase efficiency at the Rovereto plant,” said Massimo De Alessandri, chief executive of Marangoni.

The upgrade includes the latest generation of Banbury mixer capable of meeting demand for increasingly sophisticated and high-performance compounds. The mixer, to be in operation by the end of the year, will improve the quality of earthmoving tread compounds, making them more competitive for heavy-duty applications.

Another important investment made in recent months concerns the building of hot-cure retreads in a production ‘island’. The manages the entire tyre retreading process, fully automatically and flexibly.

Other upgrades are being made to the vulcanisation department, with the purchase of presses that can house 12 sector cylindrical moulds. These will further improve product uniformity by reducing the relatively frequent phenomena of ovalisation and unbalance when retreading a used tyre.

“I’m more and more convinced that there will be many opportunities for quality retreads in the future, and this is the focus of the efforts we are making to improve processes and increase efficiency at the Rovereto plant,” said Massimo De Alessandri, chief executive of Marangoni.