Cummins says it is investing in the development of low emission fuels.

By MJ Woof

February 25, 2022

Read time: 3 mins

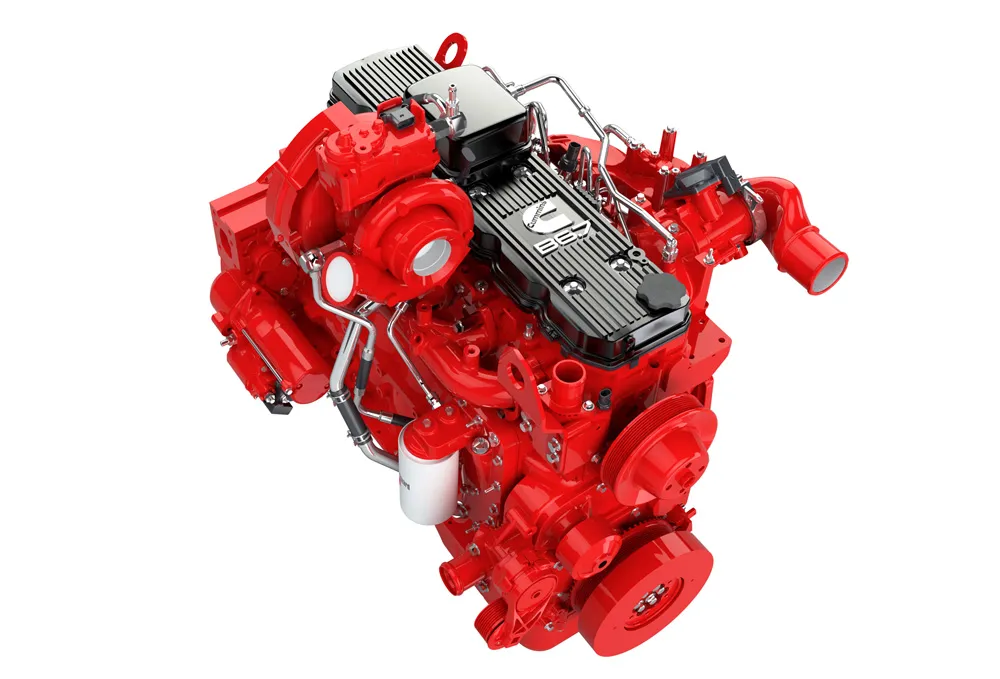

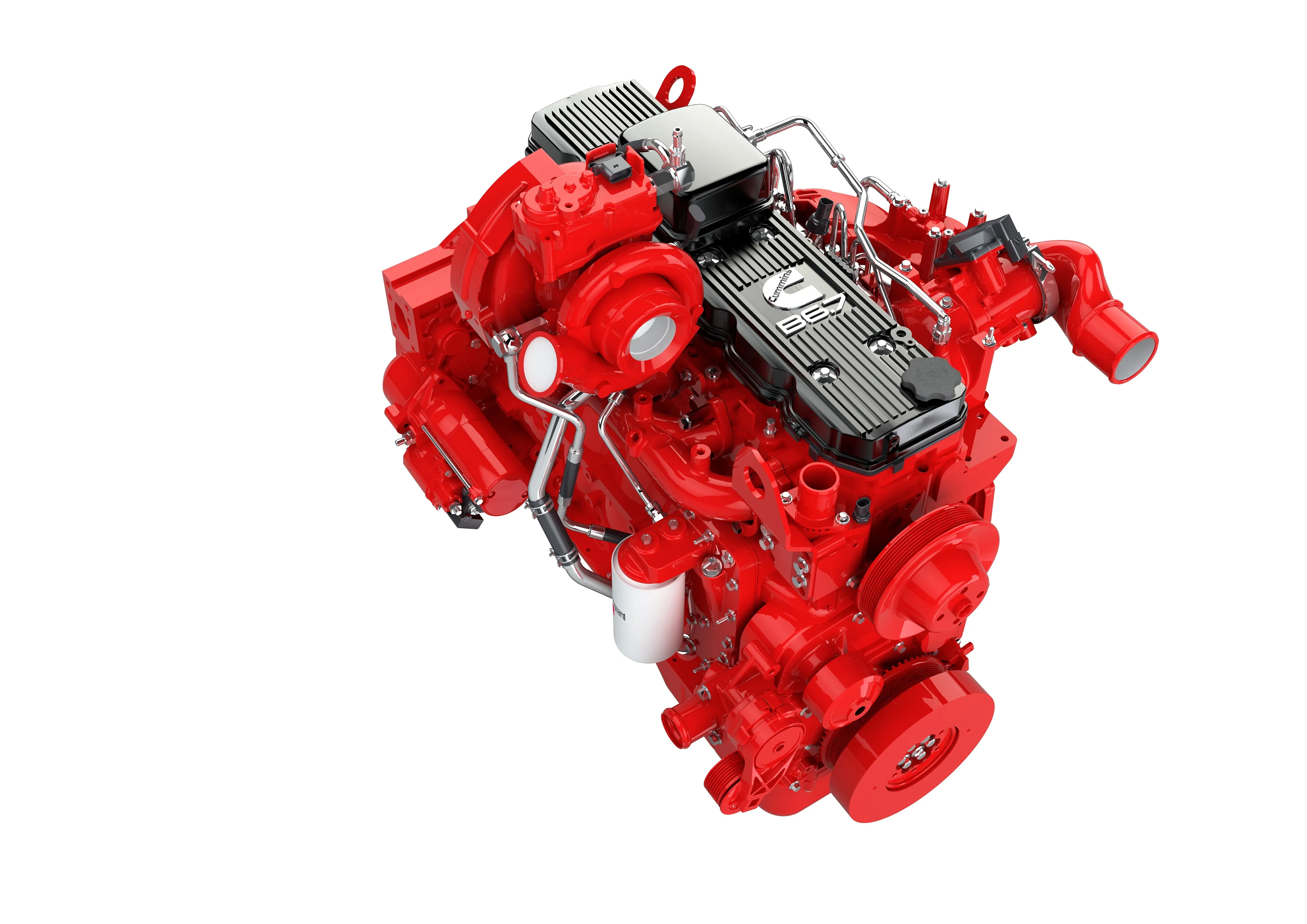

Cummins is expanding its powertrain platforms with the introduction of a range of lower carbon fuel types. As the industry’s first unified, fuel-agnostic engines, these platforms will use engine blocks and core components that share common architectures and will be optimised for different low-carbon fuel types.

“Getting to zero is not a light-switch event. Carbon emissions that we put into the atmosphere today will have a lasting impact. This means anything we can do to start reducing the carbon footprint today is a win for the planet. We need to take action now,” said Srikanth Padmanabhan, president, Cummins Engine Business. “Having a variety of lower carbon options is particularly important considering the variation in duty cycles and operating environments across the many markets we serve. There is no single solution or “magic bullet” that will work for all application types or all end users.”

These new fuel-agnostic engine platforms will feature a series of engine versions that are derived from a common base engine, which means they have a high degree of parts commonality. Below the head gasket of each engine will largely have similar components and above the head gasket will have different components for different fuel types. Each engine version will operate using a different, single fuel.

This new design approach will be applied across the company’s legendary B, L and X-Series engine portfolios - initially in on-road applications - which will be available for diesel, natural gas and hydrogen.

These fuel-agnostic platforms are designed and built-upon the learnings extracted from millions of diesel and natural gas engines manufactured and currently in-use. Today’s digital and connected technologies allow Cummins to extract insights specific to different engine duty cycles, and leverage these to design reliable fuel-agnostic platforms.

“Our customers can be confident in Cummins’ unmatched testing and evaluation process ensuring high-performance products,” claimed Jonathon White, vice president of Engineering, Engine Business. “No matter what type of work an application does, we’ll have an engine powered by lower carbon fuels with diesel-like performance to get the job done.”

These new products are an important element of Cummins’ strategy to reduce the greenhouse gas (GHG) and air quality impacts of its products and reach net-zero emissions by 2050 in a way that serves all stakeholders in a sustainable way for Cummins’ business. This commitment requires changes to Cummins’ products and the energy sources that power them.

Two of the company’s environmental sustainability goals for 2030 goals include reducing greenhouse gas (GHG) emissions from newly sold products by 25% and partnering with customers to reduce scope 3 GHG emissions from products in the field by 55 million tonnes.

“Cummins is innovating at every level of the company to find new ways of working that use fewer of the world’s resources and the Engine Business is at the center of this exciting innovation,” said Padmanabhan. “We know that our planet cannot wait for the perfect solution to happen. Instead, our approach must be a combined effort of using zero emissions power where it’s available and using cleaner power where it is not. The planet cannot afford for us to hit pause in the meantime.”