Production of construction machines is now underway at five of JCB’s UK factories. The firm announced it would partially restart work at the five facilities, having shut down the factories on March 18th due to the pandemic.

The firm had put the majority of its employees in the UK on furlough following the closure of the factories. But the plants are now active once more, though at a lower level than usual.

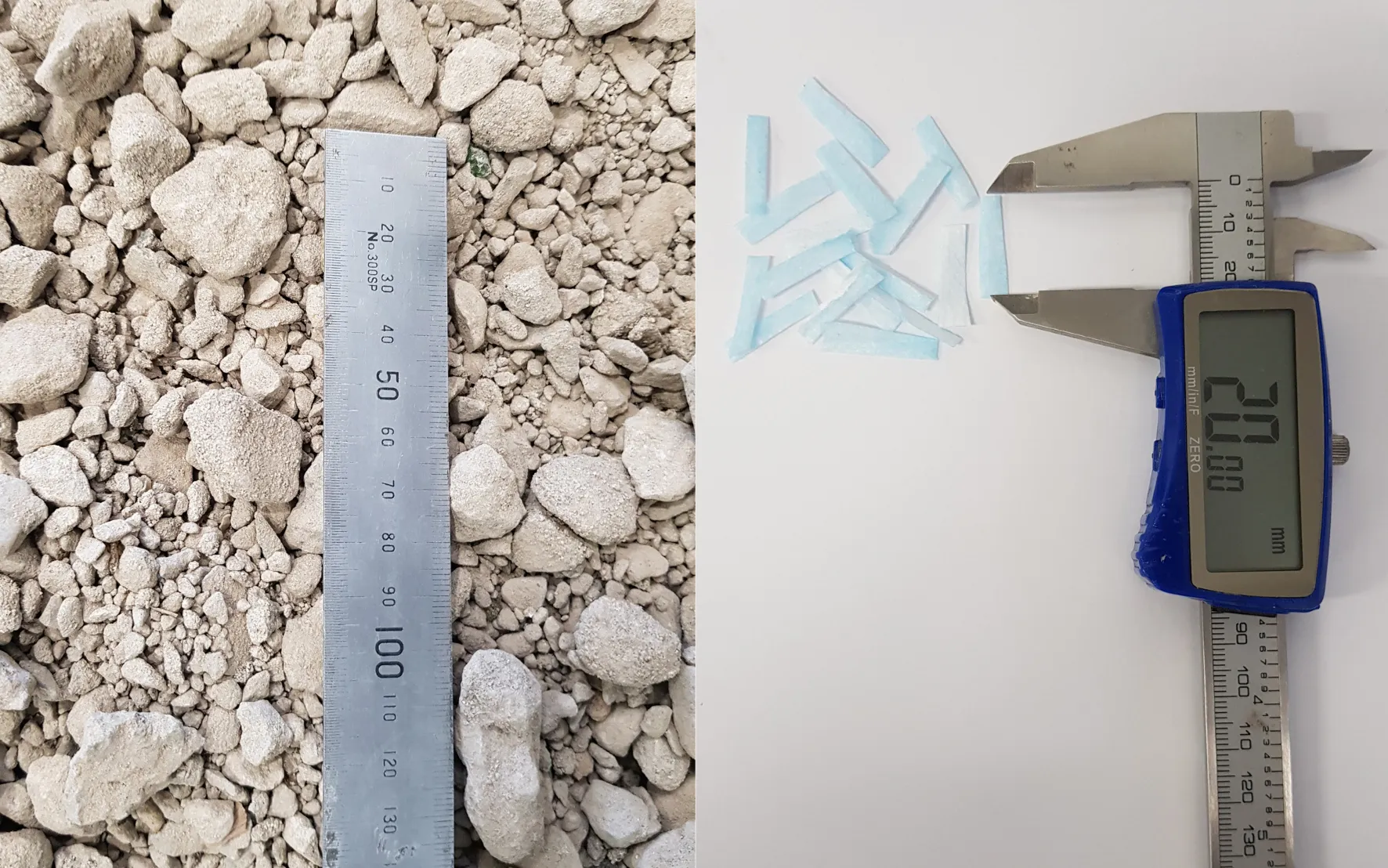

Numerous safety measures have been put in place to protect the health of the firm’s employees. Employees have to self-assess for COVID-19 symptoms before leaving home and temperature checks are overseen by medical staff for every employee arriving for work. Surgical masks have been issued to office and shop floor employees, while shop floor employees have been provided with visors for extra protection. Thermal imaging cameras will be introduced at UK plants later this month, while there is widespread provision of hand sanitiser. The firm has clearly-marked walkways and a reduction in office desks to maximise social distancing and has closed canteen facilities and vending machine, while it has suspended car sharing schemes. Lavatory hand dryers have been disabled in favour of paper towels and employees are encouraged to work at home where at all possible.

JCB CEO Graeme Macdonald said: “Production has resumed at a very low level, mainly to satisfy demand for agricultural machinery. Ahead of this re-start, an exhaustive review was undertaken to enable us to introduce wide-ranging measures that will best protect our employees. The actions we have taken ensure that safe distancing between employees on-site can be achieved at all times. In circumstances where risks are greater, additional protective visors are being provided. The health and safety of our employees is absolutely paramount as we all adjust to this new normal and the measures we have put in place will ensure we all stay healthy and avoid risks.”

The Loadall division at the World HQ, Rocester, Staffordshire, JCB Earthmovers and JCB Landpower in Cheadle, Staffordshire have resumed production along with JCB Transmissions in Wrexham and JCB Cab Systems at Uttoxeter. The move means a return to work for more than 400 employees.