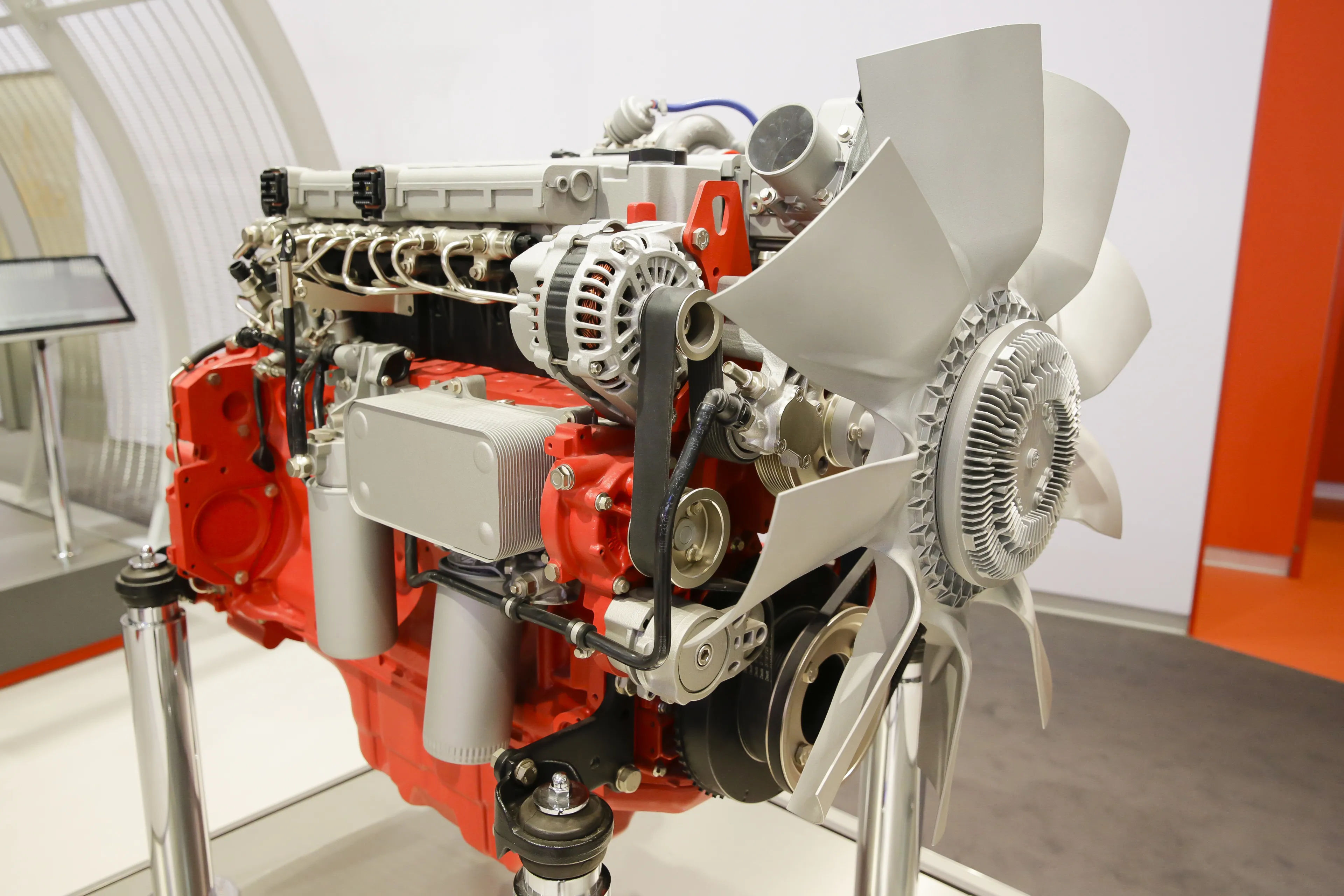

Engine manufacturer Deutz says that all of its Stage IV engines are ready for the proposed Stage V emissions legislation that will come into force in 2019/2020.

Using

The firm’s 2.9-3.6 litre engines use a Diesel Oxidation catalyst (DOC) with Selective Catalytic Reduction (SCR), while larger 4.1-7.8 litre engines operate with a Diesel Particulate Filter and SCR to meet Stage IV. For Stage V, where Particulate Matter (PM) will be counted, the company concedes that a DPF will be required for every engine, a move that can be accommodated within the DVERT system.

“It will be mandatory to use a DPF, you can’t fulfil this standard without a DPF,” said chief sales officer Michael Wellenzohn.

“But Deutz is Stage V ready. We already fulfil the Stage V emissions standard and this gives our customers a very flexible transition into Stage V. Customers running our Stage IV product today will just have to get the certification for Stage V.”