JCB is now offering a range of electric machines.

By MJ Woof

November 19, 2020

Read time: 2 mins

JCB is now offering a new range of fully-electric machines as well as fast charging systems and battery packs as part of its ‘Road to Zero’ programme. The firm has an electric mini excavator, electric 1tonne capacity site dumper, two electric forklifts and most notably, an all-electric telehandler in its construction machine range.

The new 525-60E telehandler is being offered in addition to the conventional diesel 525-60 variant. The new electric model features a lithium ion battery pack rated at 96V and which allows working for a whole shift. Using the JCB fast charging system, it can be recharged in 60 minutes, while it can also be recharged 5,000times before the pack needs replacing.

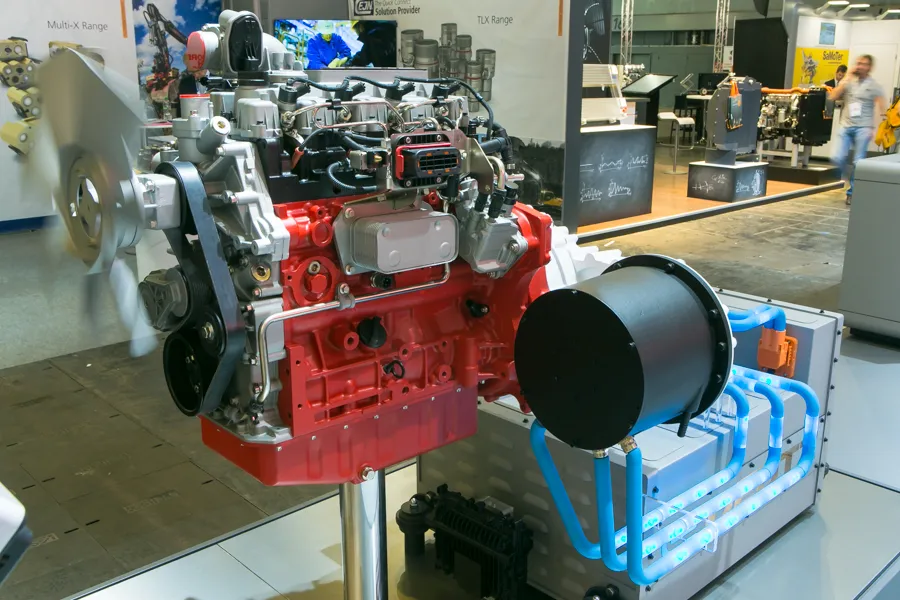

The 17kW electric motor powering the driveline is bolted directly to the transmission, so there is no need for hydrostatic motors. According to the firm this offers the same level of precision of control for inching as a hydrostatic drive, while providing much higher efficiency as well as a responsive performance. Similarly, the 22kW electric motor powering the hydraulics also offers high working efficiency and control.

The power system can operate in a wide range of ambient temperatures, ranging from 60°C down to -20°C. According to Richard Brooks, engineering director at JCB’s handling group, “The 525-60E is the same as the diesel 525-60 but with zero emissions and zero compromise on performance.”

The all-electric machine offers the same 2.5tonne lifting capacity and 2tonne capacity at 6m as the diesel model.

Because it has zero emissions, the electric machine is well-suited to duties in tunneling operations or underground carparks for example, where additional ventilation would be required to remove exhaust fumes. JCB also points out that as the electric machines have much lower working noise levels than conventional diesel models, they can be used in night time operations, without risking disturbance.