German engine manufacturer Deutz has agreed a key supply deal with Chinese construction machinery manufacturer SANY. The agreement will see SANY fitting its wheeled loaders with the TCD 7.8 diesel engine from Deutz. These engines feature diesel particulate filters and are Stage V ready. Deutz has been supplying diesels to SANY Heavy Machinery for use in other machines for some time. However this latest agreement strengthens the supply deals between the two companies. These engines meet the Tier 4 Final/Stag

August 18, 2016

Read time: 2 mins

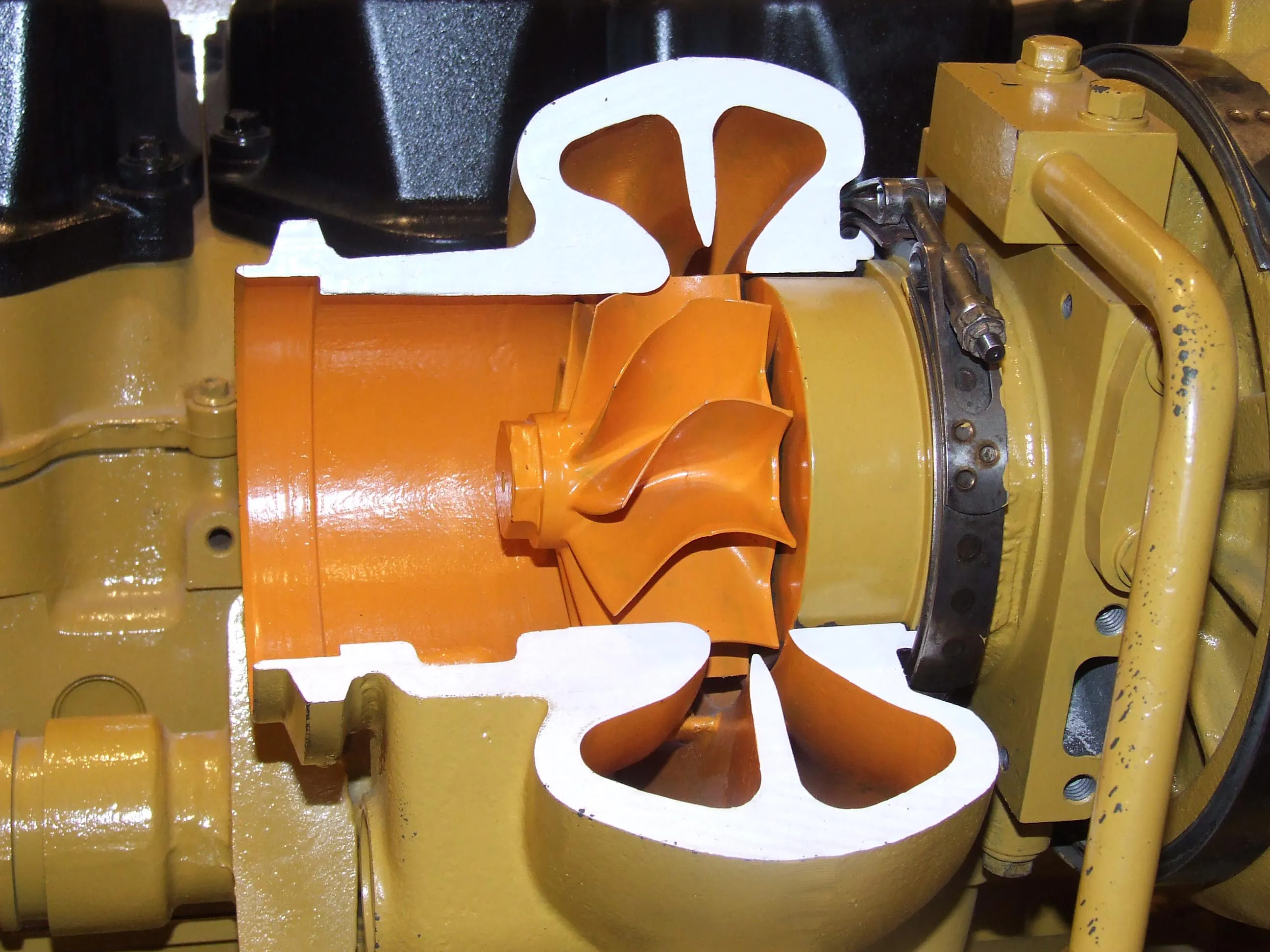

German engine manufacturer 201 Deutz has agreed a key supply deal with Chinese construction machinery manufacturer 1170 SANY. The agreement will see SANY fitting its wheeled loaders with the TCD 7.8 diesel engine from Deutz. These engines feature diesel particulate filters and are Stage V ready. Deutz has been supplying diesels to SANY Heavy Machinery for use in other machines for some time. However this latest agreement strengthens the supply deals between the two companies. These engines meet the Tier 4 Final/Stage IV emissions requirements, allowing the SANY SW405 model wheeled loaders to be sold into the US and European markets. The engines are equipped with exhaust aftertreatment technology that features a diesel particulate filter (DPF) and selective catalytic reduction (SCR). The engines will also meet the European Stage V ready emissions due to come into force in 2019, as well as complying with requirements for more strictly regulated markets such as Switzerland or municipal applications in Germany.

Chen Guizhi, head of wheel loader segment at Sany, said, "We are delighted to be collaborating with Deutz on our Stage IV wheel loader for highly regulated markets. The engine specification and modular exhaust aftertreatment is beneficial for us."

Chen Guizhi, head of wheel loader segment at Sany, said, "We are delighted to be collaborating with Deutz on our Stage IV wheel loader for highly regulated markets. The engine specification and modular exhaust aftertreatment is beneficial for us."