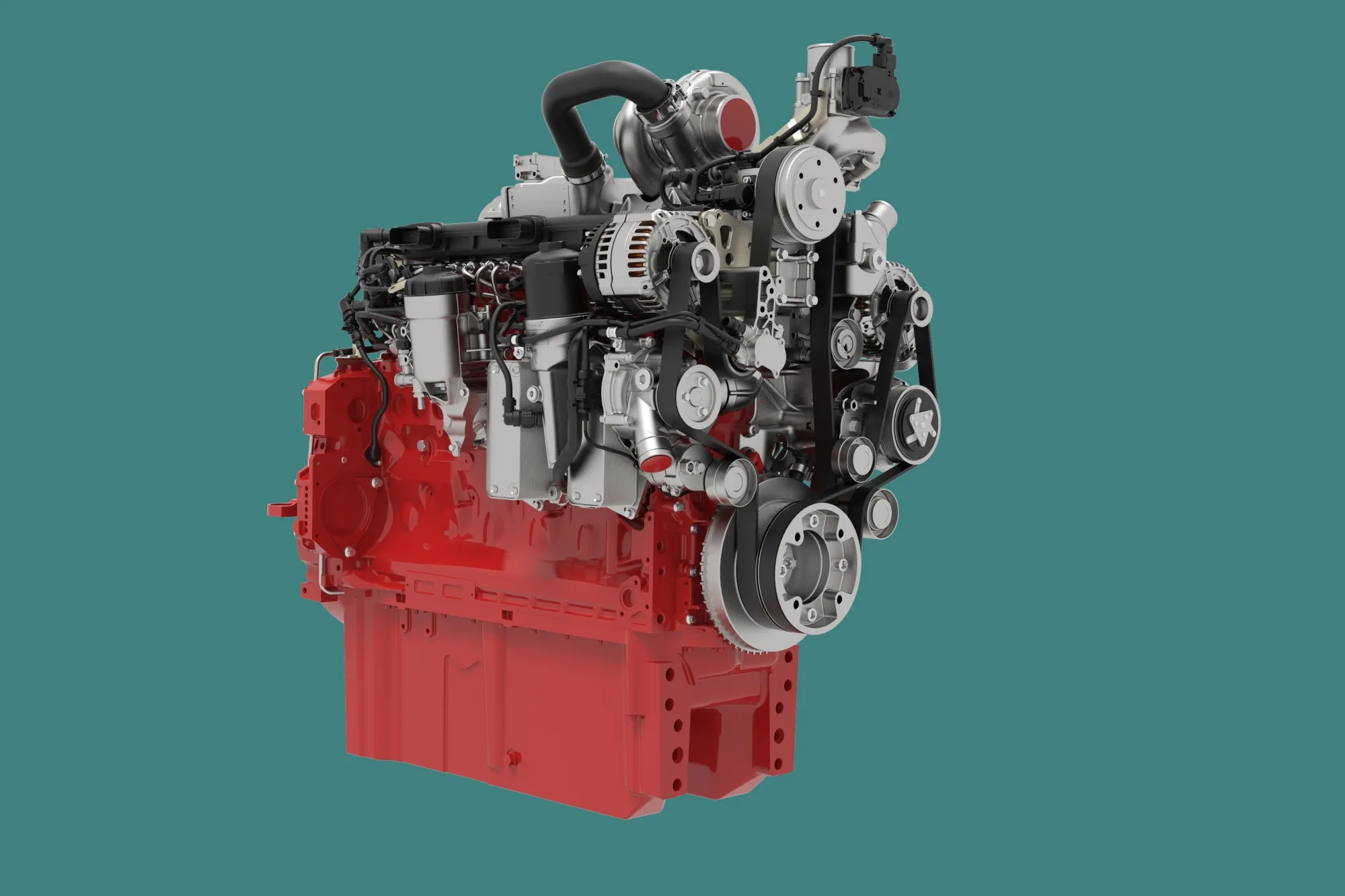

The German Federal Motor Transport Authority has now formally certified the Deutz TTCD 6.1 engine for Stage V compliance. The entire range of TCD engines fitted with diesel particulate filters will meet the requirements. ‘Stage V ready’ has now become ‘Stage V certified’. Initial certification of the TTCD 6.1 is to be followed in November 2017 by certification of the TCD 3.6, 4.1, 7.8 and TTCD 7.8.

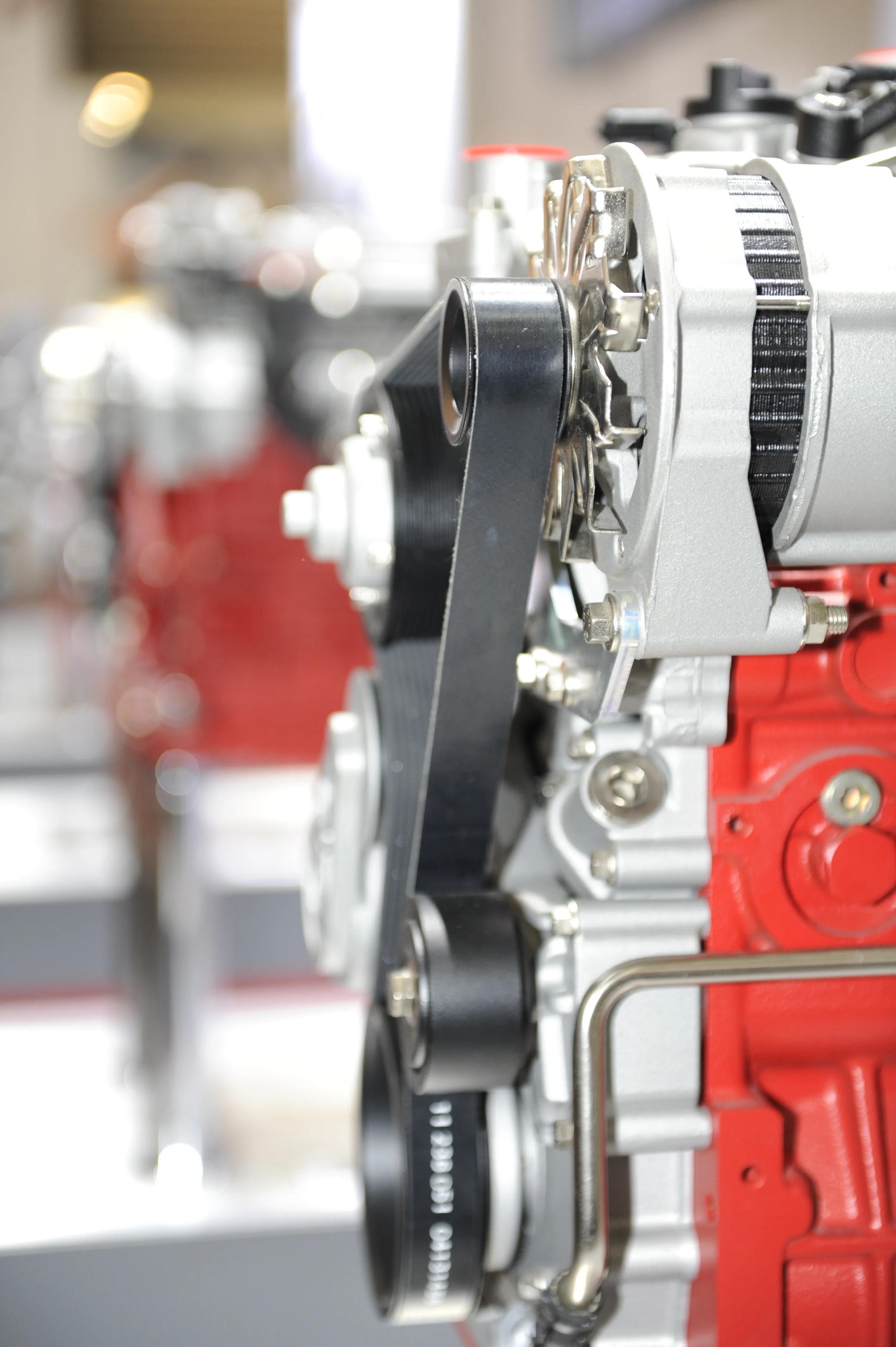

The firm says that by obtaining the EU Stage V certificate, Deutz is also delivering on its environmental promise and positioning itself as an engine manufacturer with an eco-friendly focus. The EU Stage V emissions standard represents a major challenge to engine manufacturers, mainly because the recently introduced limit on the number of particles can only be met by fitting a diesel particulate filter (DPF). Deutz has been employing DPF technology for more than 10 years and it is a standard integral feature of its TCD product range. Changing from the current EU Stage IV to Stage V requires no additional installation space, avoiding expensive modifications to customers’ equipment.

Operating a DPF demands in-depth know-how. The load profiles are completely different depending on the equipment in which the engine is installed. An intelligent ‘Heat Management’ system is needed in order to be able to burn off the particles collected in the DPF. Deutz has developed what it calls a ‘Heat Mode’ to raise the exhaust-gas temperature and to ensure the machinery is operated safely.