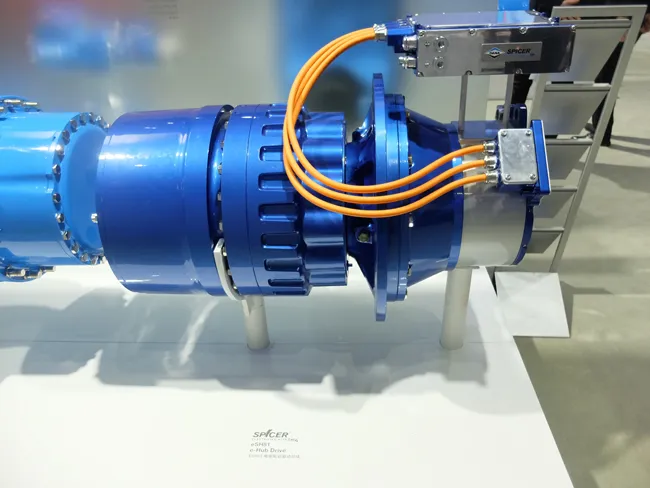

Drive specialist Dana is now offering its advanced Spicer Electrified with TM4 e-Hub Drive, a sophisticated and efficient system for heavy duty off-highway applications. Built to be robust, this new system will be suited to difficult machine applications for mining, quarrying, construction and reach stacker applications.

Dana says that the system is currently in pre-production field testing with vehicle manufacturers. The firm says that the package integrates Spicer axle expertise with Brevini planetary d

November 29, 2018

Read time: 2 mins

Drive specialist 2254 Dana is now offering its advanced Spicer Electrified with TM4 e-Hub Drive, a sophisticated and efficient system for heavy duty off-highway applications. Built to be robust, this new system will be suited to difficult machine applications for mining, quarrying, construction and reach stacker applications.

Dana says that the system is currently in pre-production field testing with vehicle manufacturers. The firm says that the package integrates Spicer axle expertise with Brevini planetary drive designs, the TM4 electric motor technology, and Dana’s advanced controls. This provides a single package said to deliver efficiency, reliability, and performance.

Dana says that the system is currently in pre-production field testing with vehicle manufacturers. The firm says that the package integrates Spicer axle expertise with Brevini planetary drive designs, the TM4 electric motor technology, and Dana’s advanced controls. This provides a single package said to deliver efficiency, reliability, and performance.

Also new from the firm is a product aimed at the grader market, the TMG14 unit. This has been designed for use in graders for the Chinese market and is manufactured at the firm’s Chinese facility. One of the first instalations of the system is on a new 164kW grader being offered by

These new drives comes at a time when Dana is expanding its range. The firm’s acquisition of Brevini brought further products to the line-up and Dana says it is now a single source supplier for axles and hub drives for example.