The US-based Association of Equipment Manufacturers (AEM) is providing information to those firms operating in Latin America. This will help increase awareness and assist manufacturers in advancing product acceptance and customer satisfaction, as well as making it easier for US-based contractors to work in Latin America. The AEM points out that non-road equipment with Tier 4 Interim/Stage IIIB generation engines with exhaust gas recirculation (EGR) and other emissions control equipment.

April 25, 2012

Read time: 2 mins

The US-based 1100 Association of Equipment Manufacturers (AEM) is providing information to those firms operating in Latin America.

This will help increase awareness and assist manufacturers in advancing product acceptance and customer satisfaction, as well as making it easier for US-based contractors to work in Latin America.

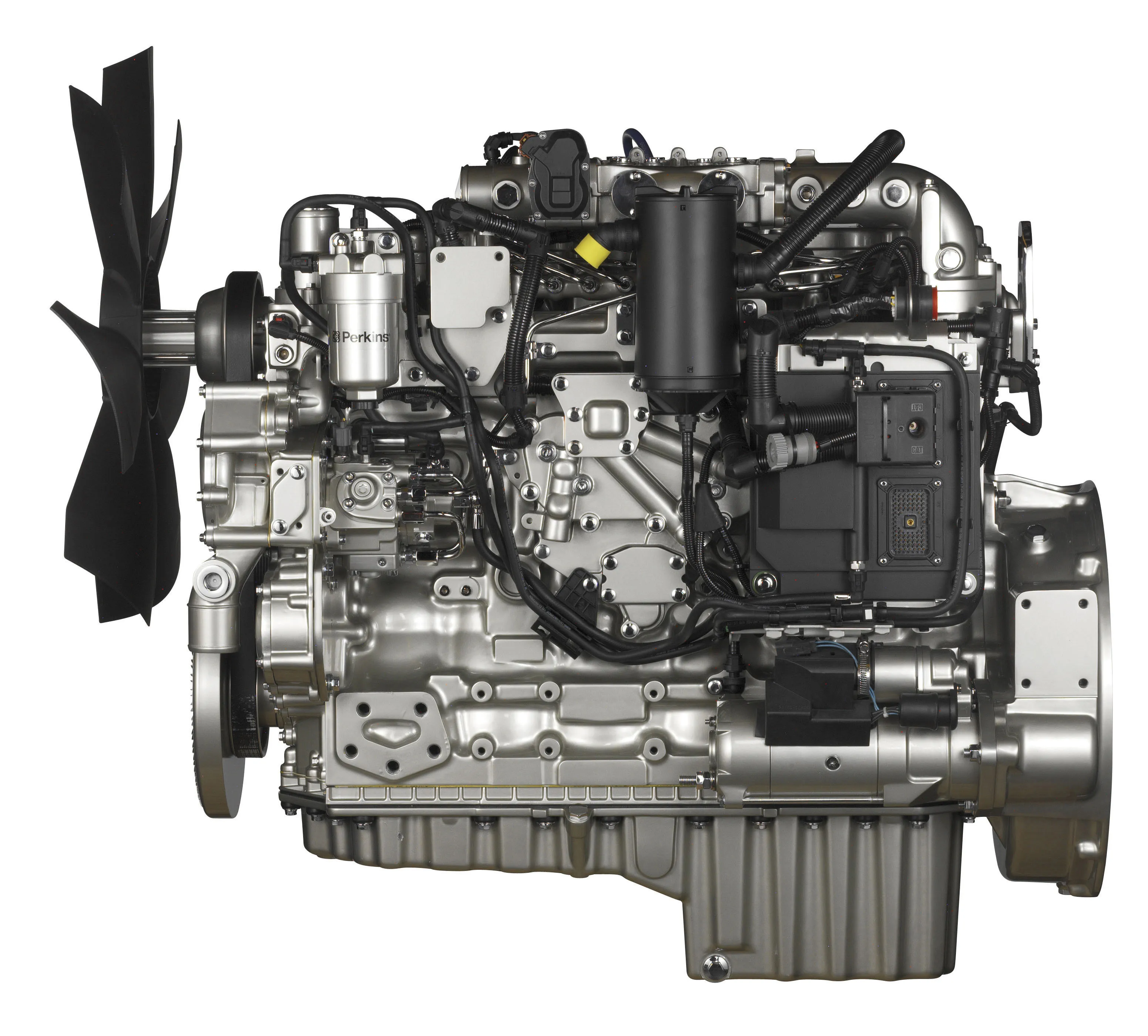

The AEM points out that non-road equipment with Tier 4 Interim/Stage IIIB generation engines with exhaust gas recirculation (EGR) and other emissions control equipment. Tier 4 Interim/Stage IIIB compliant engines require the use of ultra-low sulphur diesel fuel (ULSD) that has no more than 15ppm sulphur to comply with regulations and allow the use of specific emission reduction technologies.

They also require the use of low ash engine oil. A very high percentage of the used equipment imported to Latin America originates from countries that fall under these new emissions regulations. The AEM is providing information to those doing business in Latin America and has also produced a fact sheets in English and Spanish on the issue.

Other territories around the world also use imported equipment from areas where emission controls apply. North Africa, the Middle East and Russia have been good markets for the sale of secondhand machines from the EC, while South East Asia and Australasia provides a ready market for used machines from Japan. But there is a major risk where equipment is used improperly.

Where a used Tier 4 Interim/Stage IIIB compliant machine arrives in Latin America, operates within the territory, and consumes fuel with higher sulphur content than the 15ppm requirement, damage/failures of the engine systems such as the exhaust gas recirculation, fuel, and exhaust gas after treatment systems are likely to occur. But repairs of engine system damage caused by operation on improper fuels are typically not covered under manufacturer warranties or by service plans.

This will help increase awareness and assist manufacturers in advancing product acceptance and customer satisfaction, as well as making it easier for US-based contractors to work in Latin America.

The AEM points out that non-road equipment with Tier 4 Interim/Stage IIIB generation engines with exhaust gas recirculation (EGR) and other emissions control equipment. Tier 4 Interim/Stage IIIB compliant engines require the use of ultra-low sulphur diesel fuel (ULSD) that has no more than 15ppm sulphur to comply with regulations and allow the use of specific emission reduction technologies.

They also require the use of low ash engine oil. A very high percentage of the used equipment imported to Latin America originates from countries that fall under these new emissions regulations. The AEM is providing information to those doing business in Latin America and has also produced a fact sheets in English and Spanish on the issue.

Other territories around the world also use imported equipment from areas where emission controls apply. North Africa, the Middle East and Russia have been good markets for the sale of secondhand machines from the EC, while South East Asia and Australasia provides a ready market for used machines from Japan. But there is a major risk where equipment is used improperly.

Where a used Tier 4 Interim/Stage IIIB compliant machine arrives in Latin America, operates within the territory, and consumes fuel with higher sulphur content than the 15ppm requirement, damage/failures of the engine systems such as the exhaust gas recirculation, fuel, and exhaust gas after treatment systems are likely to occur. But repairs of engine system damage caused by operation on improper fuels are typically not covered under manufacturer warranties or by service plans.