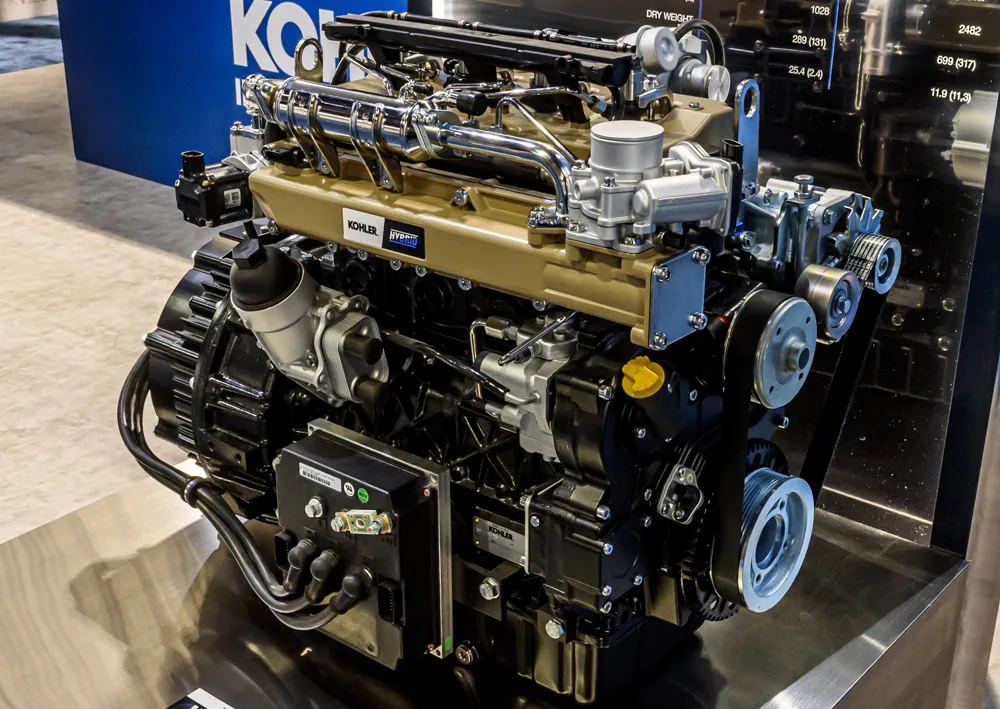

Engine firm Kohler has developed a highly sophisticated compact hybrid system that is said to reduce fuel consumption, exhaust emissions and noise. The Kohler hybrid energy module (K-HEM) system was first unveiled as an early prototype in 2019, but has now been developed further. The firm is now revealing a clear path ahead to future commercial availability for its technology, while two power packages will be offered.

The logic behind its development is clear. Using hybrid systems in construction machinery applications allows for smaller engines to be used, as the electric drive is used solely for peak power requirements. However, the K-HEM system varies from many of the competing systems as it is designed to be highly compact and for use in an array of construction machine installations and duties.

As with other hybrid packages, the K-HEM system offers a considerable reduction in fuel consumption, working noise output and exhaust emissions compared with a standard diesel engine. However, the firm also claims a better response to demand for power as well as lower running costs, delivering a reduced total cost of ownership over the life of the unit.

Instead of being a conventional series type hybrid, with a diesel driving an electric motor, the K-HEM system uses the more sophisticated parallel configuration. With this type of drive, both the diesel and the electric motor are connected to the hydrostatic motors powering the piece of machinery. According to Kohler, this layout is actually easier to install into a conventional construction machine than a series system as it requires fewer changes to the overall driveline design. In addition, the design of the K-HEM system is said to be more compact than most competing technologies as the motor is mounted directly onto the end of the diesel.

Efficiency meanwhile is said to be high for the K-HEM package. When running on diesel power alone, the motor acts as an alternator and charges the machine’s battery pack. When additional power is needed for peak performance, the electric drive functions as a motor, drawing stored power from the battery pack. The control of this switchover process is handled by a sophisticated ECU that ensures a fast and efficient response according to the firm, providing the speedy reaction to throttle demand for the additional peak power.

The package does not utilise expensive components developed exclusively for the system, however. To reduce the complexity of the set-up, the K-HEM package runs at 48V and uses conventional, proven components from the forklift and automotive sectors. This reduces cost as well as boosting reliability.

Two versions of the K-HEM package are now under development. The smaller K-HEM 1003 unit was the first unit unveiled back in 2019, featuring the 1litre Kohler diesel, which has three cylinders and delivers 18kW. Coupled with the 15kW electric motor, this allows for a total 33kW peak power performance. In addition, the electric system can deliver 8kW of continuous power. Meanwhile, emissions are low as the diesel meets the Tier 4 Final/Stage V emissions requirements. The package weighs in at 131kg and its PTO fits standard hydraulic pumps for versatility. Prototype testing is now commencing in a number of industrial machine installations (such as forklifts and access platforms) and the firm aims to have the K-HEM 1003 package in full production in 2022.

The larger K-HEM 2504 package is commencing testing slightly later and as with the smaller unit, meets Tier 4 Final/Stage V emissions requirements. This unit features a 2.5litre diesel delivering 55kW, while the electric motor can add an additional 20kW to meet peak power requirements. This system allows a maximum 75kW for peak power delivery while the electric motor can supply up to 10kW of continuous power. Again, the PTO is designed to fit standard hydraulic motors and the package shares the same configuration as its smaller sibling. Overall, the K-HEM 2054 unit weighs in at 317kg and the firm says that prototype testing is commencing in 2021, using a wider range of construction machine types than for its smaller sibling.