An array of innovative new engine and driveline developments are due – Mike Woof writes. With key construction machine events due in the New Year, various firms are already revealing plans for the future for their engines and driveline ranges and developments. Tough regulations on emissions have driven manufacturers to address this issue, while new and more efficient drives also help cut fuel use. Optimising power delivery provides an important component in reducing quantities of fuel burned, with a benefic

January 4, 2013

Read time: 4 mins

An array of innovative new engine and driveline developments are due – Mike Woof writes

Optimising power delivery provides an important component in reducing quantities of fuel burned, with a beneficial cut in CO2 emissions also. Driveline firms such as

This innovative continuously variable planetary (CVP) technology is expected to deliver greater overall vehicle efficiency and performance and will be incorporated into off-highway machines, as well as passenger vehicles and commercial vehicles. The Fallbrook NuVinci CVP technology is said to enable designers to reduce the complexity of transmissions, superchargers, and other powertrain systems. The system allows the engine to operate at more efficient speeds and is being licensed to Allison and Dana.

Through its agreement, Allison gains the exclusive rights from Fallbrook to use this CVP technology to develop primary drivetrain transmissions for certain off-highway and large stationary equipment markets. Under a separate agreement, Dana will hold an exclusive license from Fallbrook to engineer and produce transmission components and other advanced powertrain solutions with the NuVinci CVP technology for certain off-highway vehicles in the markets it serves.

Meanwhile Allison Transmission and Dana have signed a letter of intent for an alliance through which Dana would exclusively manufacture transmission components with NuVinci CVP technology for Allison.

The proprietary NuVinci CVP technology is a continuously variable transmission that is scalable and highly adaptable. It controls speed and torque and suits duties in mechanical devices that have a transmission or can benefit from speed or torque variation. This transmission uses a set of rotating balls between the input and output components. Tilting the balls changes their contact diameters and varies the speed ratio. Compared to other current transmission technologies, Fallbrook's analysis indicates that its technology is less complex, costs less to manufacture, and helps achieve optimum performance. Dana expects to have off-highway transmissions on the market featuring this sophisticated technology within five years.

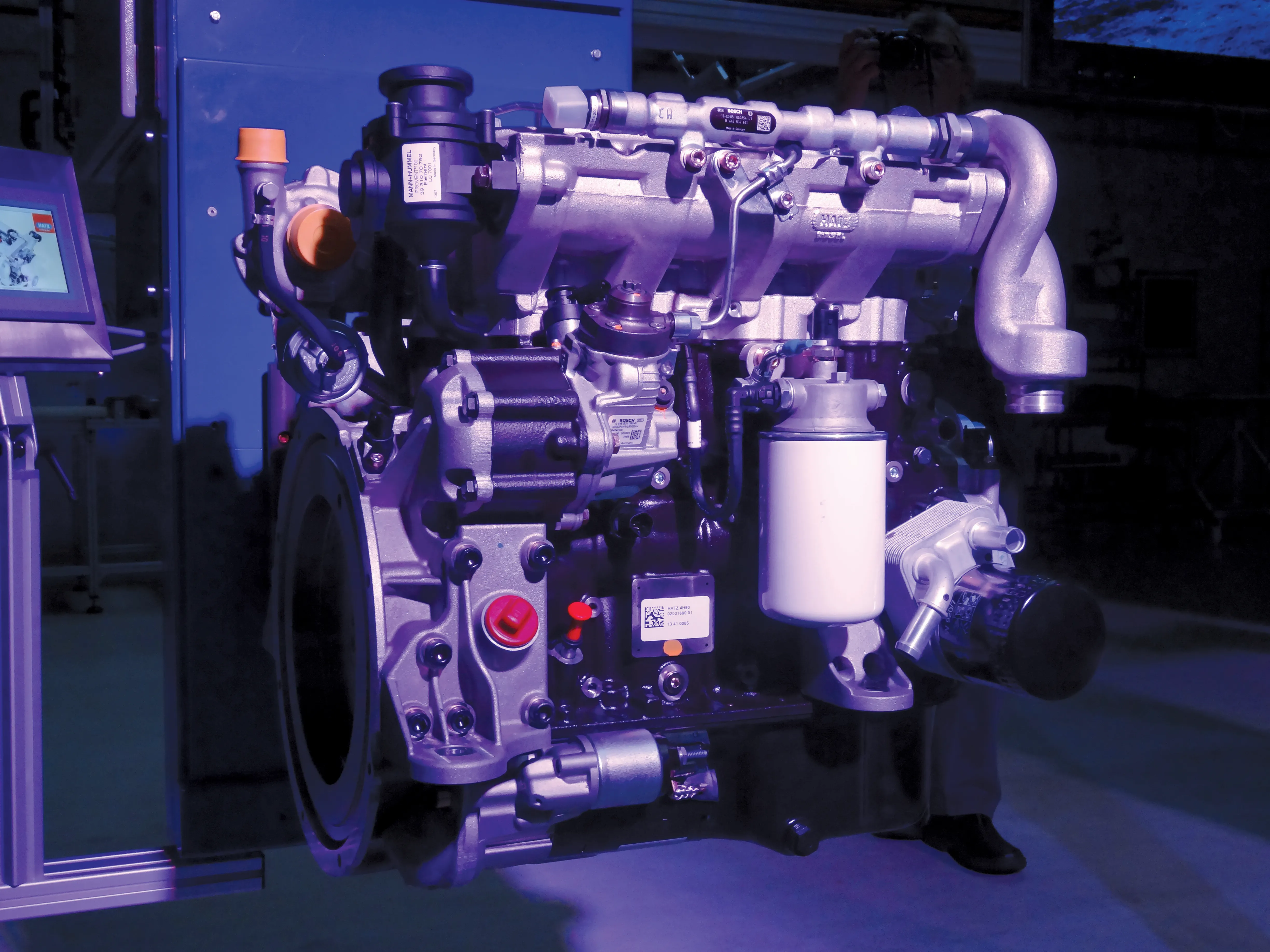

From

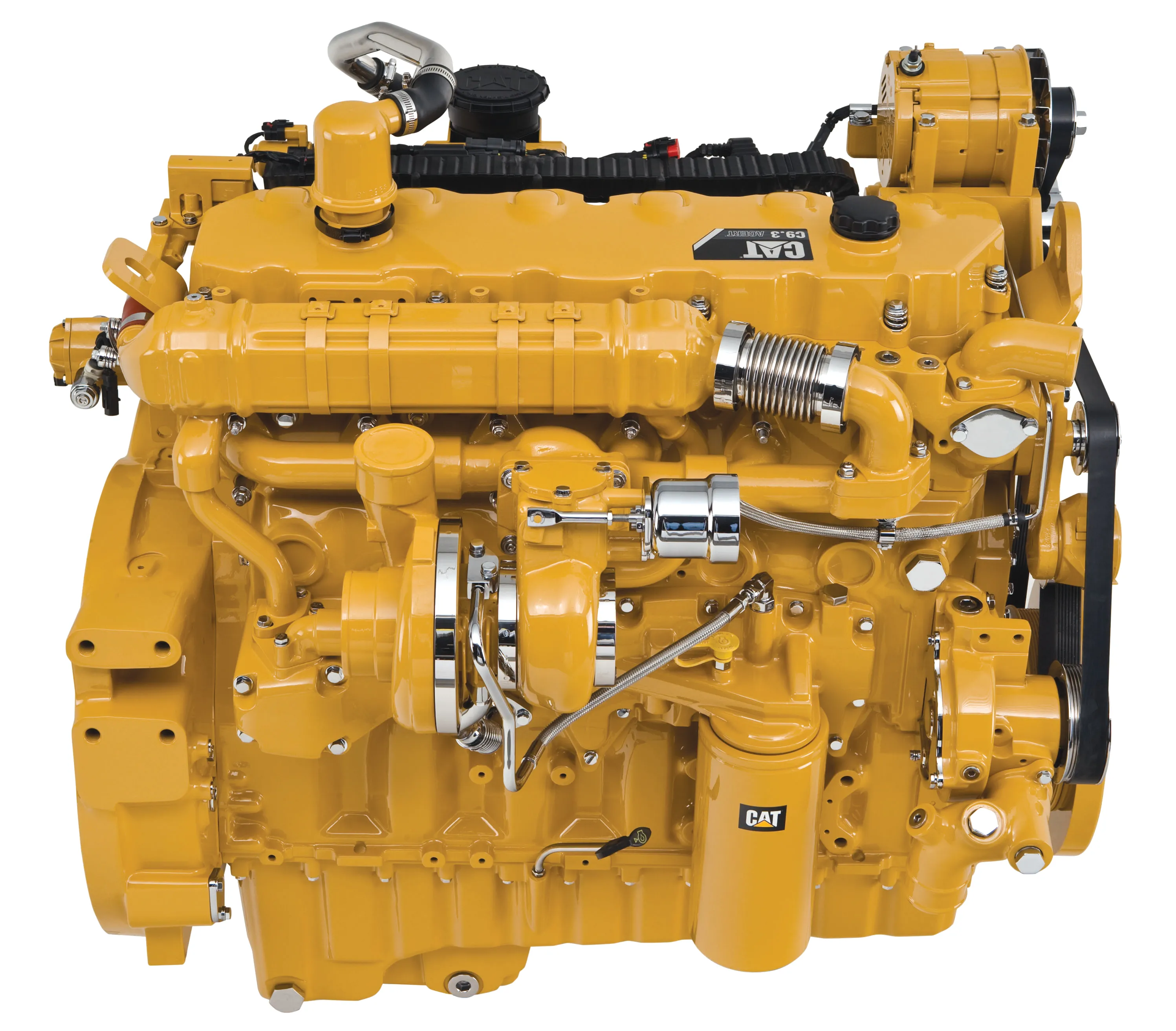

The key to its low smoke tailpipe performance is the fully-integrated clean emission module (CEM), which incorporates diesel oxidation catalyst (DOC), diesel particulate filter (DPF), and selective catalytic reduction (SCR) technology. Caterpillar’s SCR technology reduces NOx and is said to be robust and economical. The combination of the high pressure common rail fuel system and new after-treatment technology is said by ACERT to improve fuel consumption by up to 4% over the firm’s existing Tier 4 Interim/Stage IIIB compliant version of the C9.3 diesel. The CEM system is said to simplify OEM after-treatment installation and its design allows mounting in either horizontal or vertical configurations, giving users a wider range of fitting options. Caterpillar will have a full line of Tier 4 Final/Stage IV engine solutions when these are required, with power output from 25.4–895kW and the company has developed specific technologies tailored to each power band.

From