A series of key moves are being seen in the diesel engine sector, with major firms offering new solutions – Mike Woof writes Several of the major engine builders are introducing key innovations from the beginning of 2014 to meet with tough new emissions regulations for Europe and the US. Another key issue is providing solutions for engine customers in countries with less stringent regulations on emissions. Caterpillar has developed options for customers in lesser regulated countries who may wish to buy seco

January 22, 2014

Read time: 4 mins

A series of key moves are being seen in the diesel engine sector, with major firms offering new solutions – Mike Woof writes

Several of the major engine builders are introducing key innovations from the beginning of 2014 to meet with tough new emissions regulations for Europe and the US. Another key issue is providing solutions for engine customers in countries with less stringent regulations on emissions.

178 Caterpillar has developed options for customers in lesser regulated countries who may wish to buy secondhand machines with Tier 4 Interim technologies. These have been developed to cope with issues regarding fuel quality and fuel sulphur content. Based on extensive testing, analysis and field validation, Caterpillar has determined that its Tier 4 Interim engine systems with power ratings from 130-895kW (roughly 7-32litre capacity) will not require any modification to operate in lesser regulated countries. For the firm’s Tier 4 Interim engines delivering less than 130kW, the company will offer authorised modification processes that remove aftertreatment to allow them to be used in lesser regulated countries. The modification processes will include decertification and will be made available to customers through the Caterpillar dealer network from early 2014. This move is of enormous significance as the trade in secondhand machines is extensive and is enormously valuable to major manufacturers such as Caterpillar, as well as its dealer network.

There had been concern that the Tier 4 interim technologies fitted to machines would prevent the equipment from being sold into countries where fuel quality could not be guaranteed.

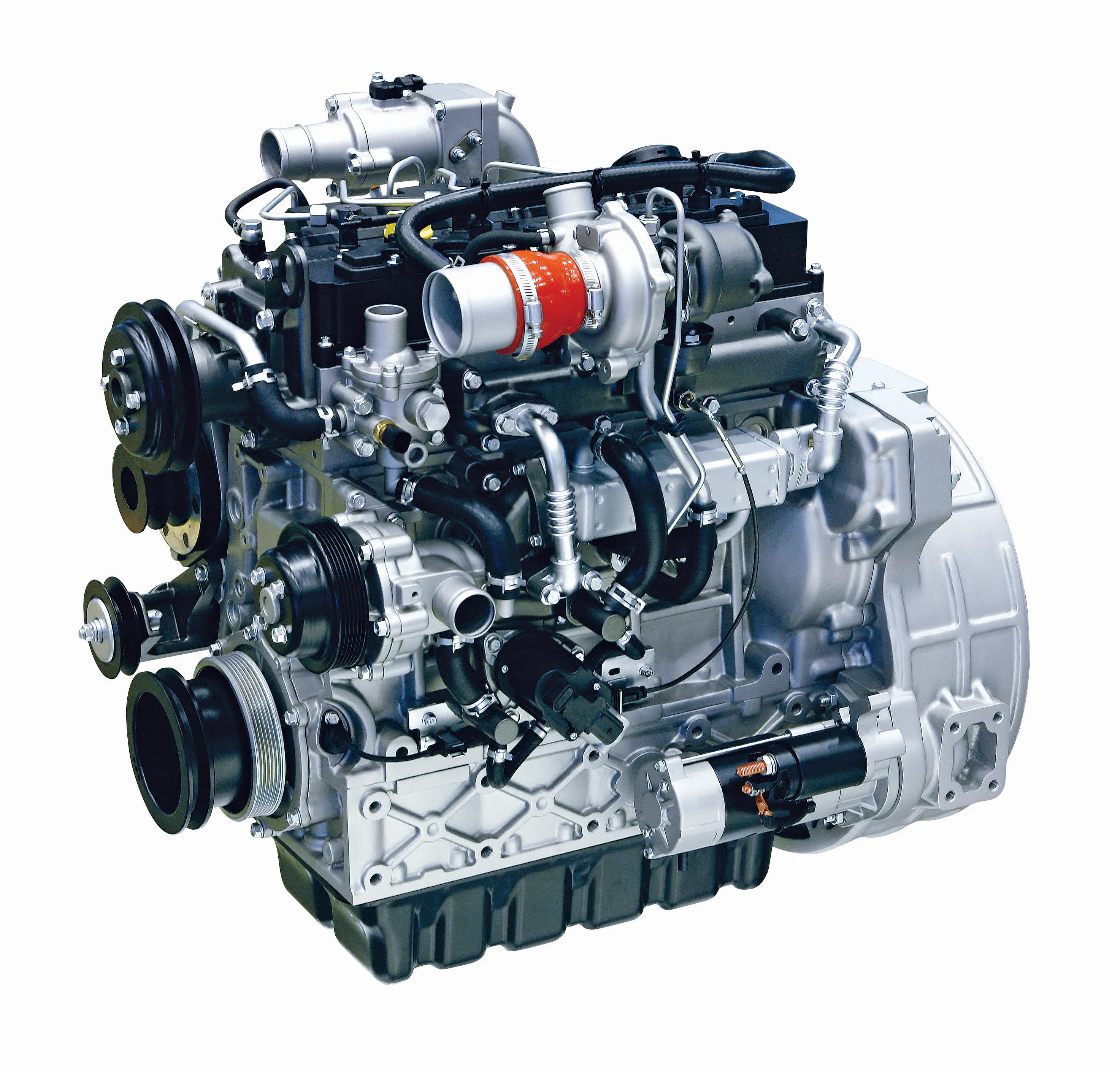

Doosan is now introducing its new compact diesel Tier 4 final and EU Stage IIIB & IV compliant engines. These engines are said to offer high power output, high low-end torque and also offer high performance for challenging applications. The engines reduce emissions of nitrogen oxide (NOx) as well as particulate matter (PM), meeting Tier 4 Final and Stage IV requirements.

Unlike engines from other firms these units feature a novel aftertreatment system. Many rival engines use both a diesel particulate filter (DPF) and a diesel oxidation catalyst (DOC) to meet the regulations but6902 Doosan Infracore has managed to eliminate the need for a DPF. This non-DPF solution requires fewer parts and also has no need for regeneration processes. And because these engines do without a DPF, maintenance needs and running costs are reduced.

299 Perkins is establishing what it describes as a customer-driven marketing approach. Customer requirements have, for many years, propelled the design and delivery of the engines manufactured by the company. In the past the firm says it has been very market-led but in recent years has introduced a programme of technology integration workshops, which have changed the way it works. This process has delivered better integration of engines into customer machines and provided improvements for the end-user. The company now has a greater regional focus, which was implemented last month, when Perkins launched its new 1104D-E44T/TA for use in lesser regulated territories at the BICES show in Beijing, China. At the same time the firm is also establishing a new approach in more regulated markets such as Europe and North America, with more resources being given to helping its customers with engine solutions.

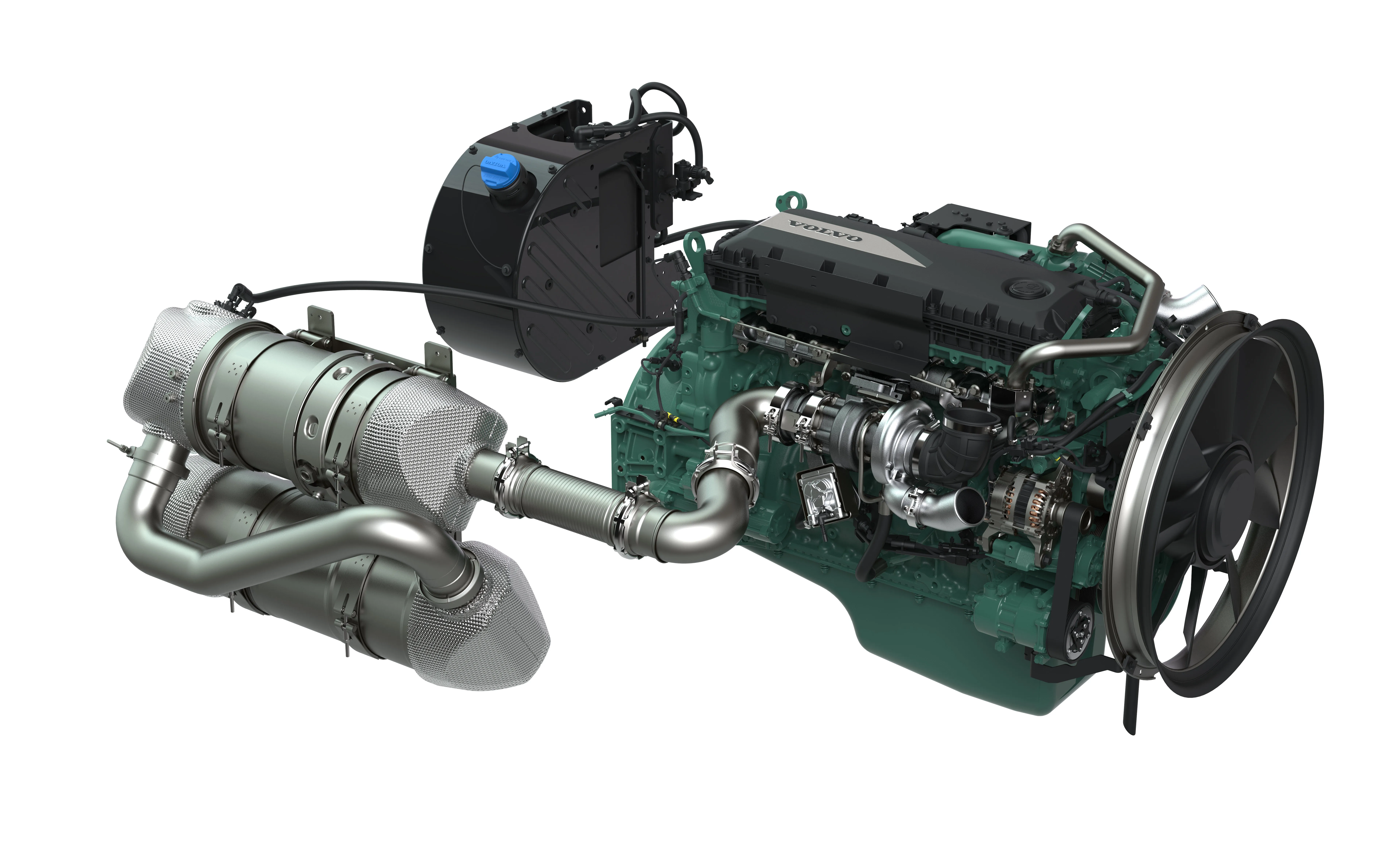

Meanwhile783 Volvo Penta is focussing on making its engines as versatile as possible, while tackling fuel economy. The firm says that it works closely with its engine customers to deliver the most compact and economical diesel solution that will provide the power and performance required. Optimising fuel consumption is a key issue in the industry, as well as meeting customer targets for uptime and utilisation.

In addition, Volvo Penta says that its latest generation control panel, the DCU2, replaces three units with one compact system, allowing for optimal compatibility and simplified engine control. The DCU2 control panel is a new generation unit that simplifies the way that operators receive, read and interpret signals from the engine. The panel is now being made available for all electronically governed engines in generator and off-highway applications from the firm.

Monitoring fuel consumption, speed and temperature, among other measurements, the DCU2 Controls the engine and allows operators to regulate RPM or shut the engine down. Fault diagnosis is said to be easier and quicker while the unit also features status updates in any of five language options.

Several of the major engine builders are introducing key innovations from the beginning of 2014 to meet with tough new emissions regulations for Europe and the US. Another key issue is providing solutions for engine customers in countries with less stringent regulations on emissions.

There had been concern that the Tier 4 interim technologies fitted to machines would prevent the equipment from being sold into countries where fuel quality could not be guaranteed.

Doosan is now introducing its new compact diesel Tier 4 final and EU Stage IIIB & IV compliant engines. These engines are said to offer high power output, high low-end torque and also offer high performance for challenging applications. The engines reduce emissions of nitrogen oxide (NOx) as well as particulate matter (PM), meeting Tier 4 Final and Stage IV requirements.

Unlike engines from other firms these units feature a novel aftertreatment system. Many rival engines use both a diesel particulate filter (DPF) and a diesel oxidation catalyst (DOC) to meet the regulations but

Meanwhile

In addition, Volvo Penta says that its latest generation control panel, the DCU2, replaces three units with one compact system, allowing for optimal compatibility and simplified engine control. The DCU2 control panel is a new generation unit that simplifies the way that operators receive, read and interpret signals from the engine. The panel is now being made available for all electronically governed engines in generator and off-highway applications from the firm.

Monitoring fuel consumption, speed and temperature, among other measurements, the DCU2 Controls the engine and allows operators to regulate RPM or shut the engine down. Fault diagnosis is said to be easier and quicker while the unit also features status updates in any of five language options.