Best known as an equipment maker, JCB has been steadily building its profile in the engine market – Mike Woof reports JCB has now produced over 200,000 engines, despite having entered this market as recently as 2004, while the company is also launching an all-new diesel. The company has built over 17,000 engines at its JCB Power Systems plant, and in excess of 30,000 atits factory in India where production started as recently as April 2011. Alan Tolley, director engine programmes said that, “…2004 was a tur

November 6, 2012

Read time: 5 mins

Best known as an equipment maker, JCB has been steadily building its profile in the engine market – Mike Woof reports

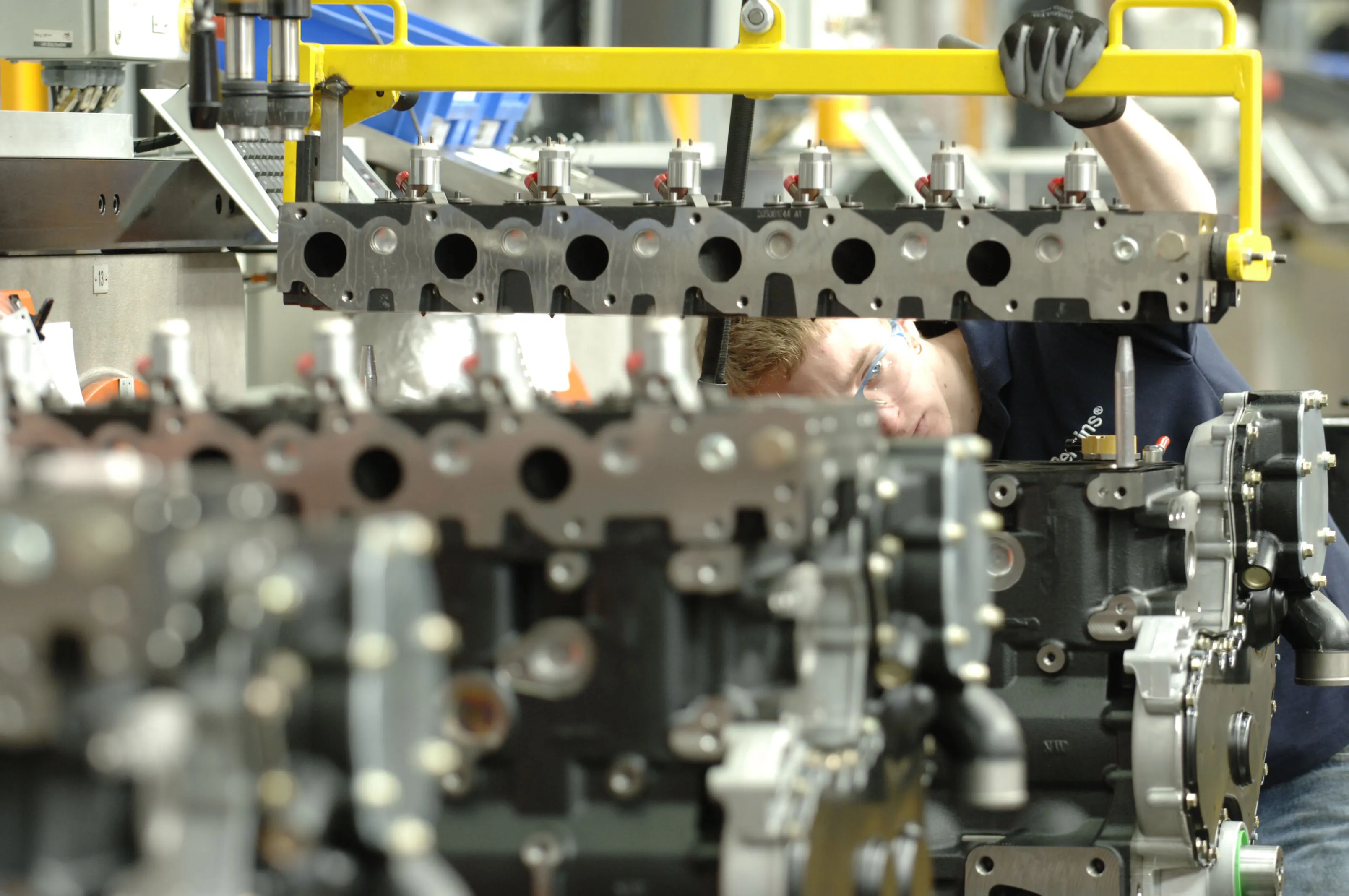

The UK engine plant is laid out for efficient output and Dan Lewis, quality manager said, “We make 220 variants here to meet all applications.”

Productivity is maximised and Robert Taylor, assembly manager said, “Every 4.2 minutes an engine is sent off down the line.”

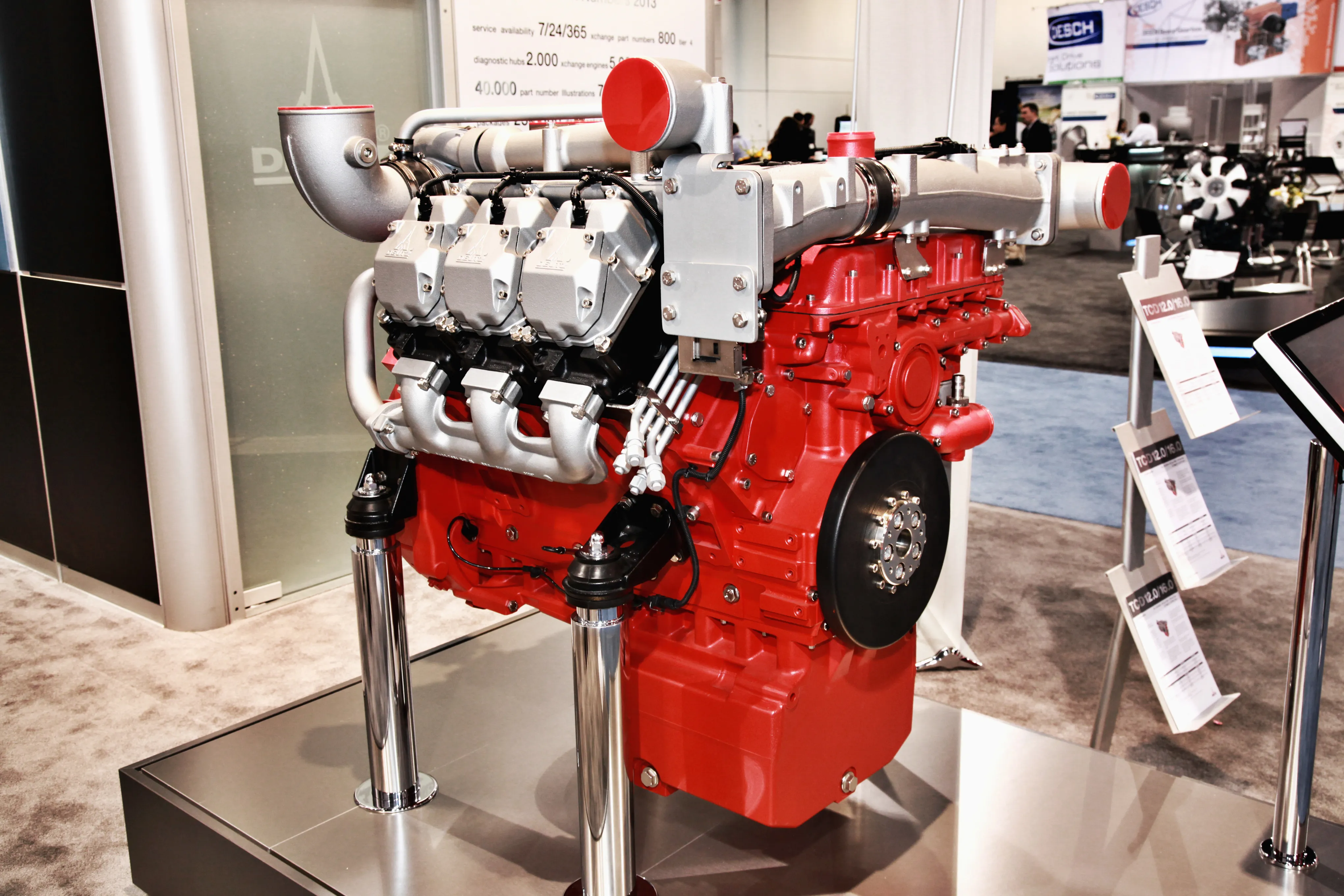

The firm is also making a major step with its new Ecomax engine, which is designed to meet the Stage IIIB/Tier 4 Interim emission regulations. JCB is offering a radical alternative to its rivals also, as the engine can be re-rated for markets with no exhaust emissions requirements.

Tolley explained the reliability and durability will be maintained from the earlier engines and said, “Ecomax has allowed us to innovate and meet the requirements of the emissions legislation.”

Ollie Howlett is engine service manager at JCB and said, “In recent years companies have gone for diesel particulate filters (DPF) and after-treatment for low emissions. We came up with an elegant solution, with no DPF and no after-treatment.”

Dispensing with the DPF means there is no need to use fuel to regenerate the unit periodically, as well as reducing long-term maintenance needs. And this is a significant benefit for the customer as it will reduce running costs. He explained that the cooled EGR system helps lower the temperature in the combustion chamber and reduces the formation of nitrous oxide. Key features for the engine include the variable geometry turbocharger, the design of the EGR cooler and the EGR valve system.

Meanwhile

Other key benefits of the Ecomax include its broader spread of power outputs, with an increase at the top end to a maximum of 129kW and a low output rating of 55kW. Further savings are offered to running costs in that the Ecomax diesels run on standard engine oils with no additional service requirements and are also fully compatible with JCB’s Livelink monitoring package.

Despite the fact that the Ecomax engine is new to the market, JCB says that it has been extensively tested, with 110,000 hours of testing in 70 different machines. And Tim Burnhope, chief innovation and growth officer said, “The benefits to the customers go far beyond the engine.”

The issue of low sulphur fuel availability has been a key talking point in the equipment sector. While Stage IIIB/Tier 4 Interim engines need quality fuels with low sulphur levels, these are not sold in developing markets. Equipment previously sold from Europe or North America into developing nations will have to remain in these markets, because these will not be suitable for sale into countries where quality fuel is unavailable. A major advance with the Ecomax engine is that it can be recalibrated by a JCB dealer for use in non-legislated markets. Howlett said, “It maximises the residual value to our customers.”

With a network of 2,000 or so dealers worldwide there should not be a problem with finding a specialist trained in this operation.

The process entirely removes the emissions equipment though, meaning that the machine cannot be used even in markets with lower emissions restriction and is suitable only for those areas with no legislation whatsoever. A stamp on the engine shows that the emissions kit has been reduced. However, it is also possible for a JCB dealer to refit the emissions package, retest the machine and re-certificate it for use in emissions controlled markets should the need arise. Even with the emissions kit reduced, power, torque and fuel consumption figures remain broadly the same.

The process of taking away the emissions control kit is comparatively simple and involves removing the EGR unit, reducing the injection pressures and recalibrating the electronics. This is a significant development. Some engine firms have developed processes that will allow them to remove emissions equipment from diesels, but the work required is more complex and takes time. For JCB, the ability to remove the emissions systems will allow secondhand sales of its machines into markets where fuels still contain sulphur and there is no legislation in hand at present covering engine emissions, such as India and Russia.

Work is also in hand to develop a method for reducing the emissions standard, from Tier 4 Interim to Tier 2 for example, which would allow equipment to be sold into markets such as China or parts of Latin America where intermediate emissions legislation is in place.