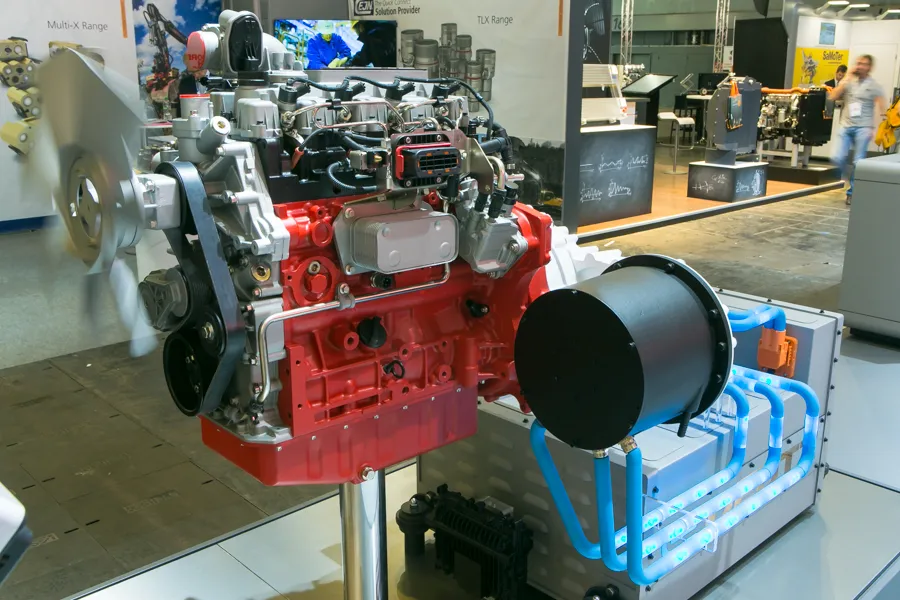

The firm says that its sophisticated K-HEM Series units use the more efficient parallel hybrid configuration, rather than the simpler series hybrid system which is less efficient.

A series hybrid system converts chemical energy into mechanical energy, and this is converted in turn into electrical energy. However, a parallel hybrid system can deliver mechanical energy, coming from chemical energy, at the same time as it delivers electrical energy, coming from a previously-charged battery pack. This offers the advantage of using mechanical and electrical energy simultaneously. The combination of the two types of energy is the main advantage of any parallel hybrid system.

The parallel hybrid K-HEM hybrid units can be fitted directly onto the hydraulic system of a machine, just as with a conventional internal combustion engine.

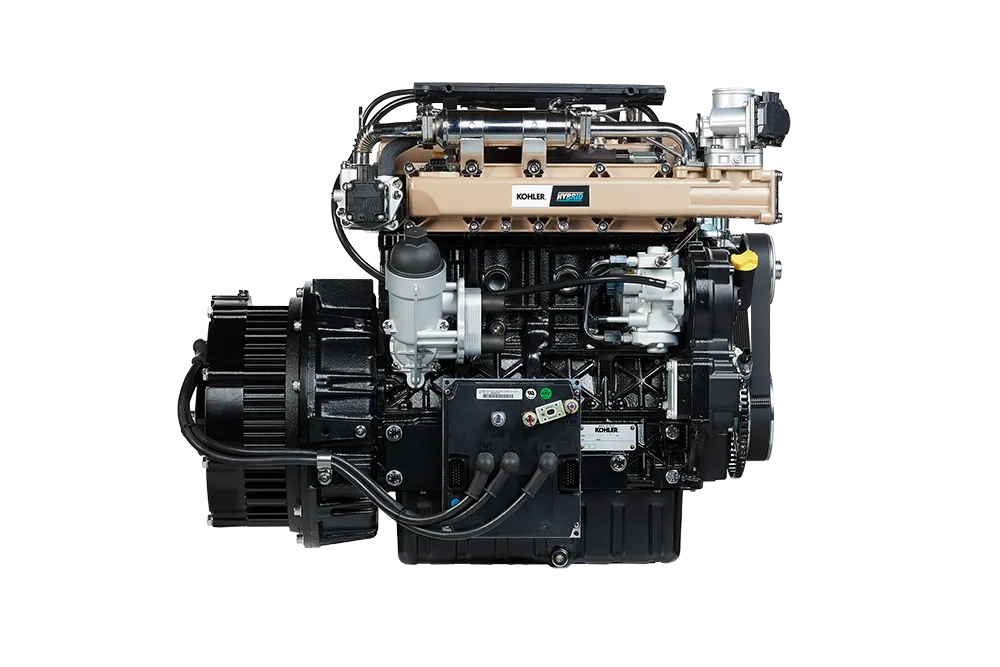

The K-HEM 2504 is a hybrid unit that combines a KDI 2504TCR 55.4kW diesel (that meets Stage V emissions legislation without SCR), and a 48V electric motor that allows 19.5kW peak power and 9kW constant power. The new K-HEM 2504 hybrid unit offers efficient Diesel Particulate Filter (DPF) management for regeneration processes, as it is uses the temperatures reached to recharge the battery pack.

The advanced KDI 2504TCR engine delivers a high performance and the combination with electrical power can equal, if not exceed, the performance offered by higher output engines in terms of power, as well as a smaller footprint.

The K-HEM 1003 unit generates power using a combination of a KDW 1003 18kW diesel (meeting Stage V standards without DPF), and a 48V electric motor that delivers 15kW of peak power and 9kW of continuous power. This means that the unit is capable of providing over 30kW without the need for exhaust gas aftertreatment systems. The K-HEM can also operate as a generator for energy accumulation systems.

The K-HEM hybrid units have been designed to meet the needs of equipment with intermittent duty operation cycles that have occasional power peaks, as well as continuous low load operation cycles. With the K-HEM system, the majority of the power is provided by the combustion engine, while the power peaks are provided by the electric motor.

The K-HEM Package is lighter and more compact than comparable engines and allows the user to benefit from the combination of mechanical power and electric power. The engines are less complex and have no need of the sophisticated aftertreatment systems, while the hybrid allows the ability to store and use excess energy. Users can manage operations using the master control unit, while the package offers a reduction of noise and exhaust emissions, as well as lower fuel consumption.

The diesel engine ensures maximum performance in specific operating conditions, while the hybrid unit allows optimal output for peak power requirements, boosting productivity. The dual function of the electric component, which works both as a generator and as an auxiliary motor, allows energy recovery from the transmission system during braking and exhaust phases and from the combustion engine during operating phases with low energy demands. The energy stored in the battery is available when the machine requires more than the threshold of 18kW of installed power, exceeding even 30kW. This reduces exhaust emissions, fuel consumption and installed power.

Kohler claims that the high degree of integration between the mechanical and hydraulic components makes it possible to optimise machine management. Each actuator can be managed by the hydraulic or electrical system depending on specific requirements, and controlled by the master control unit that oversees the system.

Italian access platform manufacturer CELA is one of the first construction machine manufacturers to utilise the innovative Kohler K-HEM 1003 hybrid system in its new DT28 model.

As the engine does not require aftertreatment systems, the downtime caused by DPF regeneration has been eliminated.