Guy Woodford reports on the imminent global market launch of Hatz’s keenly-awaited new four-cylinder diesel engine – the 4H50TIC Due to be available to customers from January 2014, Hatz’s new water-cooled, four-cylinder 2litre 4H50TIC diesel engine is said to be partly the result of unprecedented financial sacrifices made by the German firm’s employees during the global economic crisis.

January 22, 2014

Read time: 4 mins

Guy Woodford reports on the imminent global market launch of Hatz’s keenly-awaited new four-cylinder diesel engine – the 4H50TIC

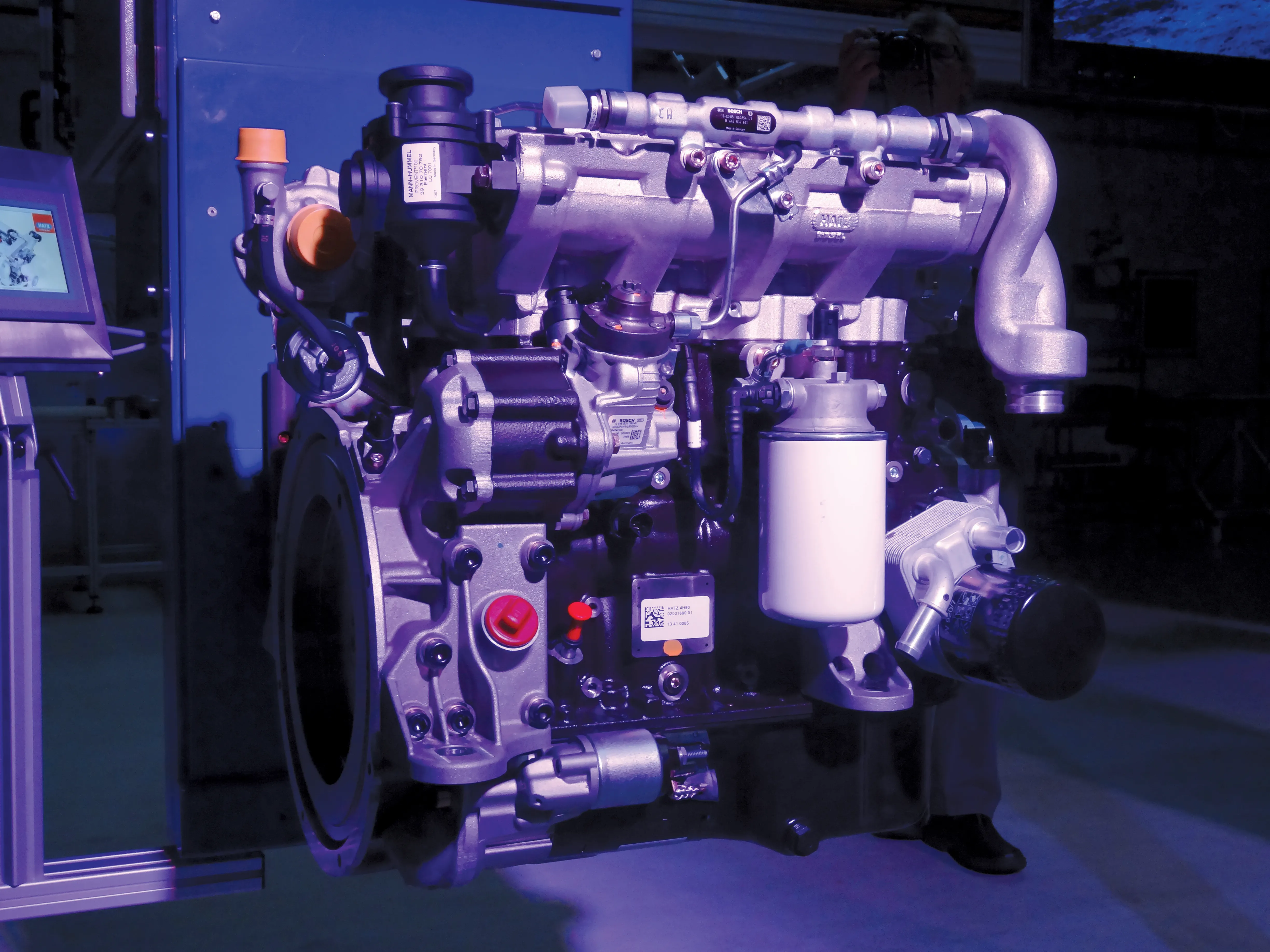

Due to be available to customers from January 2014,7125 Hatz’s new water-cooled, four-cylinder 2litre 4H50TIC diesel engine is said to be partly the result of unprecedented financial sacrifices made by the German firm’s employees during the global economic crisis.

Speaking at an in-house press event showcasing the new 4H50TIC, while also highlighting the company’s plans for other new H-series engine models and illustrating Hatz’s over-130 years of diesel engine innovation, Hatz commercial managing director Wolfram Hatz said, “It was outstanding how our staff worked together to overcome the [2008-9 financial] crisis. When our staff agreed not to receive their vacation and Christmas bonus [from 2009 to 2012] they contributed €5-€6 million which we used for the 4H50.”

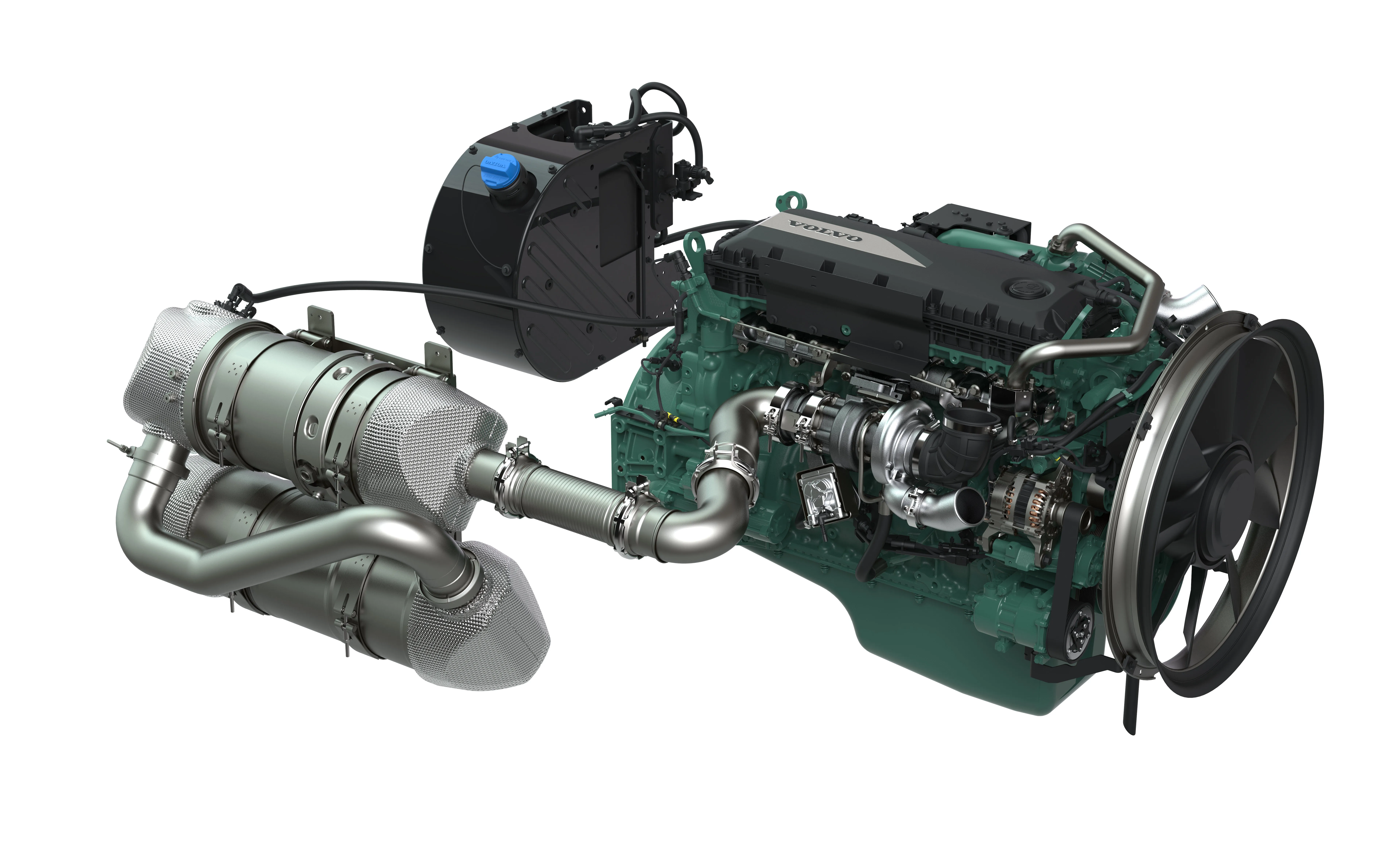

The 4H50TIC is equipped with the latest3405 Bosch common-rail technology, turbocharger, exhaust gas recirculation (EGR), and a robust diesel oxidation catalyst. Hatz claims the extremely low emission values, performance and fuel efficiency of the engine “set benchmarks” in the 37-56kW class.

In its development of the 4H50TIC, Hatz says its engineers concentrated on reducing engine size and weight while maintaining a high performance and excellent exhaust gas values. This has resulted in a turbocharged 2litre engine that achieves a maximum output of 55kW and weighs only 173kg. Fulfilling the Stage IIIB and Tier 4 Final emissions standards, the exhaust aftertreatment on the 4H50TIC requires only a robust engine oxidation catalyst (DOC), which, in contrast to a diesel particulate filter (DPF), is maintenance-free and built for the engine’s lifetime.

Additionally, the DOC works without electronics. Hatz says the use of a DPF is not necessary due to the reduction in the particulate matters during the combustion process, but can be adapted as an option for regional and local regulations.

Hatz says the 4H50TIC engine has many application possibilities such as in mini excavators, wheeled loaders, forklifts, drills, pavers, pumps and generators.

The firm says the 4H50TIC will be looking to achieve around 8% of the 37-56kW industrial diesel engine global sales market share, with sales of the engine likely to focus primarily on EU member states, the US and countries where requirements for low emission engines are stipulated.

While offering a standard maintenance interval of 500 hours, Hatz claims the 4H50TIC can have an extended maintenance interval depending on its application.

The engine also has what Hatz says is a sophisticated sensor system which can shut off the engine in an emergency to avoid damage.

The 4H50TIC is equipped with two valves per cylinder, said by Hatz to aid the engine’s “high efficiency, mechanical robustness and functional simplicity.” For all essential parts, such as fuel injection, crankcase, crankshaft and exhaust gas recirculation valve, Hatz has sourced only premium products from mostly German suppliers.

Pilot applications of the 4H50TIC are said by Hatz to show a fuel saving potential of around 30% compared to an EU Stage II engine. The high fuel efficiency of the 4H50TIC is, says Hatz, partly due to a reduction of internal friction, achieved by the conservative design with very few moving parts. For example, the use of a timing belt and timing chain is not necessary as the valve train is driven through a gear, push rods and rocker arms.

Numerous 4H50TIC prototype engines have been installed in test vehicles such as wheeled loaders, excavators, trash water pumps and mobile floodlights. As part of Hatz’s internal quality management, the company says all new engine model components are subject to a practical test of 1,000 operating hours in different load conditions and work environments. Specific customer requirements can also be incorporated into this development process.

Manufacturing around 60,000 engines a year at the firm’s Ruhstorf, southern Germany HQ, Hatz says a three-cylinder version of the 4H50TIC is already in development and will, depending on the start of the next stage of emissions legislation, become available to customers from 2016 onwards.

Due to be available to customers from January 2014,

Speaking at an in-house press event showcasing the new 4H50TIC, while also highlighting the company’s plans for other new H-series engine models and illustrating Hatz’s over-130 years of diesel engine innovation, Hatz commercial managing director Wolfram Hatz said, “It was outstanding how our staff worked together to overcome the [2008-9 financial] crisis. When our staff agreed not to receive their vacation and Christmas bonus [from 2009 to 2012] they contributed €5-€6 million which we used for the 4H50.”

The 4H50TIC is equipped with the latest

In its development of the 4H50TIC, Hatz says its engineers concentrated on reducing engine size and weight while maintaining a high performance and excellent exhaust gas values. This has resulted in a turbocharged 2litre engine that achieves a maximum output of 55kW and weighs only 173kg. Fulfilling the Stage IIIB and Tier 4 Final emissions standards, the exhaust aftertreatment on the 4H50TIC requires only a robust engine oxidation catalyst (DOC), which, in contrast to a diesel particulate filter (DPF), is maintenance-free and built for the engine’s lifetime.

Additionally, the DOC works without electronics. Hatz says the use of a DPF is not necessary due to the reduction in the particulate matters during the combustion process, but can be adapted as an option for regional and local regulations.

Hatz says the 4H50TIC engine has many application possibilities such as in mini excavators, wheeled loaders, forklifts, drills, pavers, pumps and generators.

The firm says the 4H50TIC will be looking to achieve around 8% of the 37-56kW industrial diesel engine global sales market share, with sales of the engine likely to focus primarily on EU member states, the US and countries where requirements for low emission engines are stipulated.

While offering a standard maintenance interval of 500 hours, Hatz claims the 4H50TIC can have an extended maintenance interval depending on its application.

The engine also has what Hatz says is a sophisticated sensor system which can shut off the engine in an emergency to avoid damage.

The 4H50TIC is equipped with two valves per cylinder, said by Hatz to aid the engine’s “high efficiency, mechanical robustness and functional simplicity.” For all essential parts, such as fuel injection, crankcase, crankshaft and exhaust gas recirculation valve, Hatz has sourced only premium products from mostly German suppliers.

Pilot applications of the 4H50TIC are said by Hatz to show a fuel saving potential of around 30% compared to an EU Stage II engine. The high fuel efficiency of the 4H50TIC is, says Hatz, partly due to a reduction of internal friction, achieved by the conservative design with very few moving parts. For example, the use of a timing belt and timing chain is not necessary as the valve train is driven through a gear, push rods and rocker arms.

Numerous 4H50TIC prototype engines have been installed in test vehicles such as wheeled loaders, excavators, trash water pumps and mobile floodlights. As part of Hatz’s internal quality management, the company says all new engine model components are subject to a practical test of 1,000 operating hours in different load conditions and work environments. Specific customer requirements can also be incorporated into this development process.

Manufacturing around 60,000 engines a year at the firm’s Ruhstorf, southern Germany HQ, Hatz says a three-cylinder version of the 4H50TIC is already in development and will, depending on the start of the next stage of emissions legislation, become available to customers from 2016 onwards.