Engine makers are looking to the future and are working ways to ensure that their engines will be able to use alternative fuel types. Several major firms have announced projects that will allow the use of lower carbon fuel types as alternatives to conventional diesel.

Cummins and Kohler in particular have announced important engine development projects in this regard.

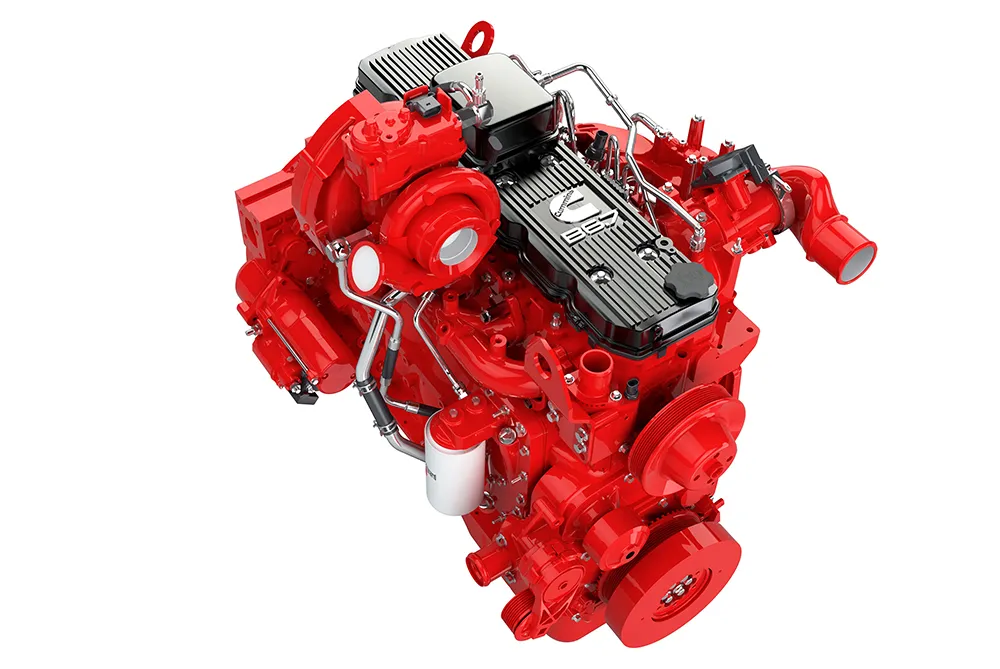

Cummins is expanding its powertrain platforms with the development of a range of unified, fuel-agnostic engines. The firm says that these platforms will use engine blocks and core components that share common architectures but will be optimised for the use of different low-carbon fuel types.

Srikanth Padmanabhan, president, Cummins Engine Business commented, “Having a variety of lower carbon options is particularly important considering the variation in duty cycles and operating environments across the many markets we serve. There is no single solution or “magic bullet” that will work for all application types or all end users.”

These new fuel-agnostic engine platforms will feature a series of engine versions derived from a common base engine, which means they have a high degree of parts commonality. Below the head gasket, each engine will largely have similar components and above the head gasket will have different components for different fuel types. Each engine version will operate using a different, single fuel.

This new design approach will be applied across the company’s B, L and X-Series engine portfolios, initially in on-road applications, which will be available for diesel, natural gas and hydrogen.

Meanwhile, Kohler Engines recently approved use of EN15940-compliant Hydrotreated Vegetable Oils, or HVOs, for all its diesel engines, either pure or as a blend with conventional diesel. This is a significant step for the firm as the use of HVO will enable a reduction in CO2 emissions of up to 90%, with no engine modifications needed.

The approval came after intensive laboratory and on-the-field testing by Kohler’s engineering team. The group’s diesel engines do not require any kind of modification or specific upgrade to use HVO. However, use of exhaust gas aftertreatment systems will still be necessary where already required.

HVO is also known as synthetic diesel and renewable diesel and is produced with plant or animal oils derived from the residues of the meat and fish industries. As such it does not use agricultural resources or contribute to deforestation. A reduction in overall CO2 emissions of up to 90% can be obtained depending on the raw material. Compared to most conventional diesel fuels, HVO also benefits from low sulphur content and its use lowers exhaust emissions, as well as being 100% fossil free and 100% recycled.

HVO fuel can be distributed, handled, and stored like conventional fuels. Pure or blended, it can be used in any Kohler engine, whether liquid-cooled from the KDI and KDW lines or air-cooled from the KD line. In addition, no variations to the maintenance schedule are required and normal European warranty conditions apply.

“We are witnessing a growing interest from customers for use of synthetic fuel (HVO) and other renewable fuels. eFuels are especially interesting, not only for their positive environmental impact but also because they reach performance levels comparable to diesel fuels,” stated Luigi Arnone, senior manager of Diesel Engine Engineering at Kohler, adding, "…HVO is a stable fuel that doesn’t require any engine modifications or additional maintenance.”

HVO fuel has a lower density, meaning that the mass of fuel injected/cycle is lower than that of EN590 diesel, reducing power and torque performance by 1% and 5% respectively. This effect is partly compensated by a higher cetane number, which translates into positive effects on combustion.