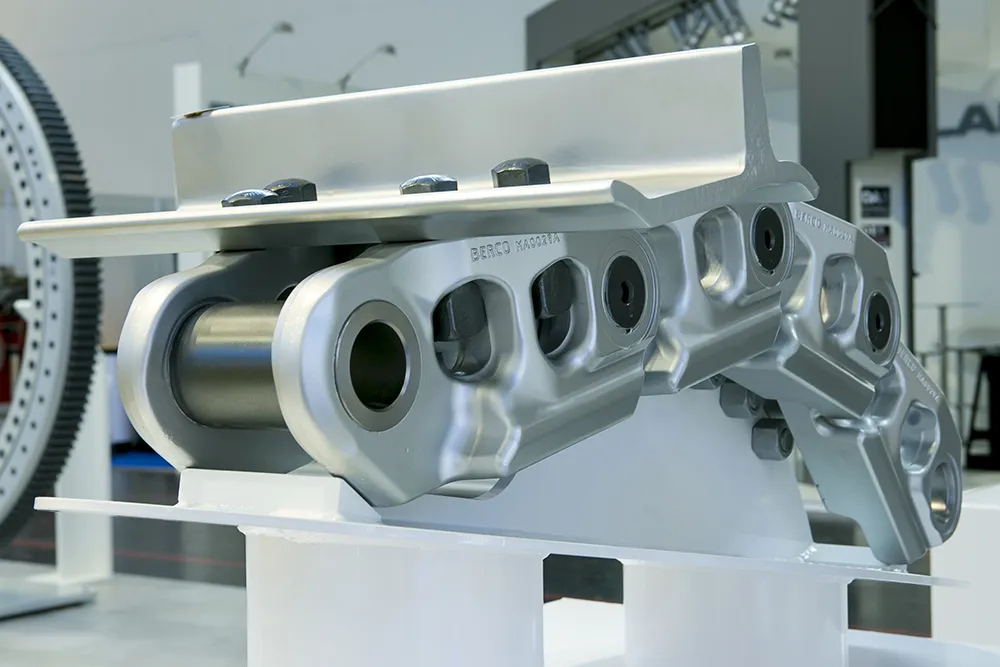

Two of the most innovative are said to be the Robustus (ROtating BUShing Undercarriage System) and BPR2 (Berco Positive Pin Retention2 System). Robustus is a specially engineered system that is used for D5 and D6 class dozers. The Rotating Bushing system, in conjunction with BPR2 is said to increase the life of the lubricated track group assemblies in applications operating in abrasive terrain, reducing ownership and undercarriage costs. This is of particular importance, given that the undercarriage accounts for 50% or more of the total lifetime cost of a machine.

In a machine fitted with a conventional undercarriage, bushings (outer diameter) are constantly subjected to wear because bushings-sprocket bushings slide onto the sprocket tooth roots during engagement. With Robustus, bushings rotate when engaged by a sprocket, reducing the wear rate of the bushings. This is claimed to deliver up to a 35% increase in track life, allowing a maximum of 6,000 hours of operation without maintenance, reducing operating costs by up to 30%. Now in its third generation, Robustus is compatible with existing frames and standard components of D6 and D6 classes. In addition, the conversion to these units can be performed easily.

The performance of Robustus is further strengthened by another Berco innovation: BPR2. The Robustus system features four sealing points instead of two as in a conventional design. However, the BPR2 system provides more reinforcement on the sealing points. This system uses a metal ring plastically deformed as a mechanical locking element. This ring is pressed in between pin and link, locking the joint to specific predetermined end-play levels. BPR2 prevents end-play generation and increases the sealing of the joint by at least 25%, boosting track life.

The use of the BPR2 system on conventional track group assemblies is usually recommended for heavy-duty applications such as extraction, heavy construction or demolition. These conditions generate large loads and impacts, twisting the chain and generating axial movements. Even machines equipped with wide shoe arrangements can mount BPR2 in order to ensure the reduction of torsional effects on the joint.

Another recent challenge for Berco has been to extend wear life of undercarriage components used in heavy excavators for extraction applications. The travel rate of an undercarriage can vary significantly between different operations. When blasting is being carried out for example, the heavy machinery will have to be withdrawn from the working area for safety. In situations such as this, it is recommended to use carburised bushings, as they are suitable bushings for reducing the rate of wear.

For applications with lower travel needs however, undercarriage parts are still subjected to wear. Continuous hammering of the front shovel for example may not wear out the bushings quickly, but the forces generated can cause cracks on bushings instead. Berco’s solution has been to use both quenched and tempered, and induction hardening and tempering (IHT) bushings. The quenched and tempered steel with added boron increases hardenability. These specially produced bushings provide greater value when fitted on reinforced chains.

This solution is designed for heavy application such as for track chains used on 200-400tonne machines, as it provides high resistance to wear as well as resistance to impact. Being capable of achieving up to 20,000 hours of use in the field it ultimately reduces ownership and undercarriage costs.

Another pioneering development is the use of rotoforged steel for rollers used in demanding applications. This innovative process is expected to deliver significant benefits to machines that have a huge load transfer in their working times, such as large excavators used in the extraction markets that weigh above 200tonnes. For applications of this size, the rollers are under particular pressure as they carry the inertia of the machine.

Steel that has undergone this novel heat treatment process acquires a high microstructure and compactness, to such an extent that it is able to achieve toughness values double those of conventional steel. Continuous casting steel is usually rolled. Rolled steel that undergoes the new rotoforging process has its microstructure transformed down to the core, resulting in a much stronger and tougher structure.

For this reason, rollers made from rotoforged steel are said to be suitable for machines that operate in the most demanding working environments. These components are said to offer a very high level of reliability and a wear life of 15,000-20,000 hours.