The DuraLine Plus pads are made of abrasion resistant Malaysian rubber suitable for a wide range of machines, said Martyn Pointer,

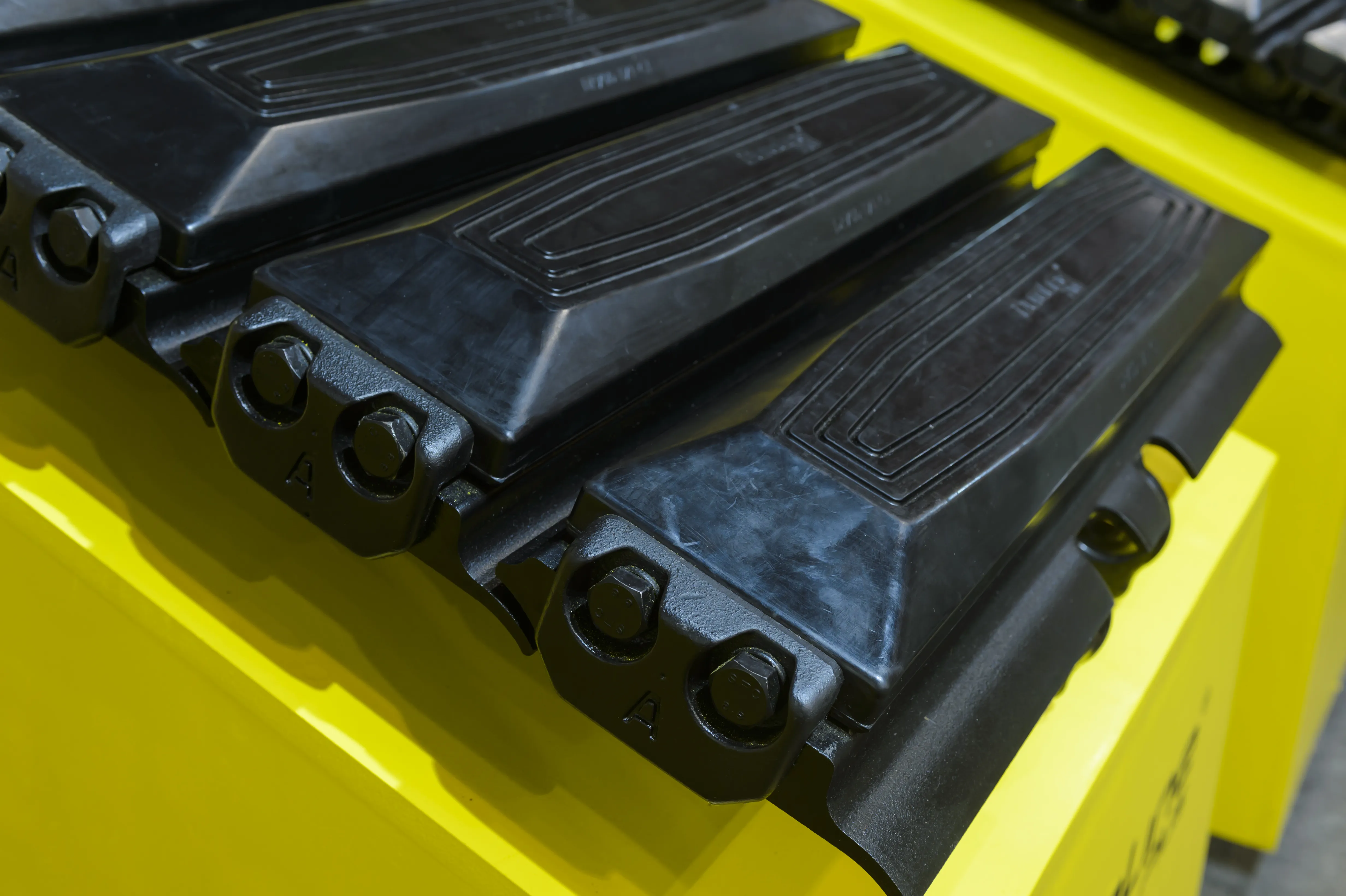

The chunky one-pied vulcanised Roadliner version of the pad bolts directly onto the steel track train of machines in the 4-26 tonne range. The pad has an internal steel core specially treated during vulcanisation to ensure a secure bond between rubber and steel. An interlocking design reduces the build-up and clogging of material during operation. Widths range from 400-600mm.

Roadliner pads are secured via four fixed bolts onto the centre of the track chain. Meanwhile, the clip-on version allows a faster attaching process - up to half the time - as well as offering a longer life. The clip-on have a fixed bracket on one side and a secure clamp on the other. Widths range from 400-800mm.

Astrak’s bolt-on version is similar to the clip-on version. It’ four bolts are set wider apart than on the Roadliner version to allow it to fit onto the track shoe instead of the chain. They come in widths between 400-600mm.