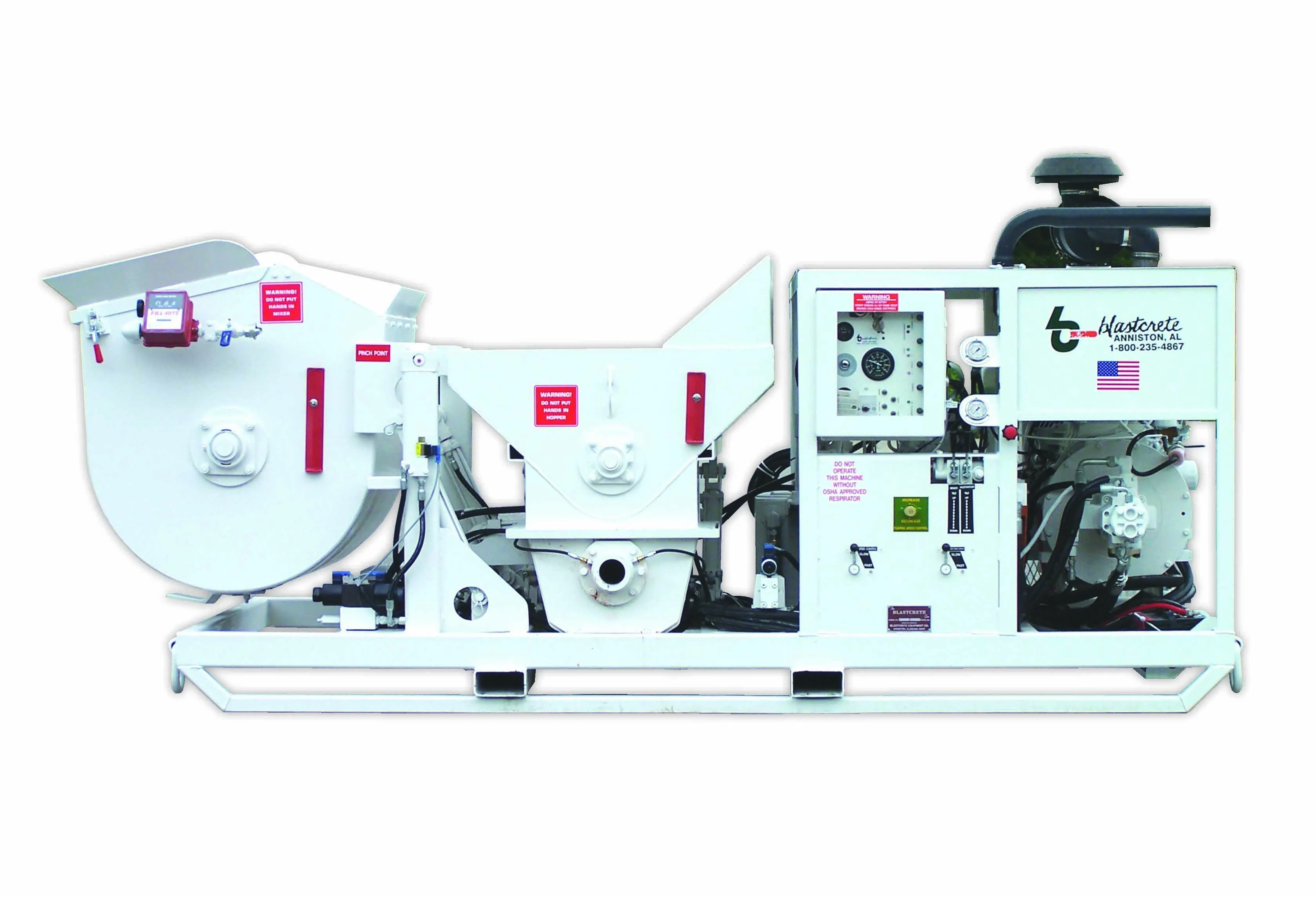

Blastcrete Equipment claims that its RMX-5000 mixer/pump offers 15% more pumping pressure than any other machine in its class. The RMX-5000 is one of five mixer/pumps in Blastcrete’s lineup for refractory, shotcrete and concrete repair and is said to be user-friendly, safe and rugged enough to handle demanding installations. The efficient unit is available with either a spiral mixer or a paddle mixer with a planetary gearbox. The spiral mixer is designed for conventional shotcrete in applications such as br

January 6, 2015

Read time: 2 mins

The efficient unit is available with either a spiral mixer or a paddle mixer with a planetary gearbox. The spiral mixer is designed for conventional shotcrete in applications such as bridge repair projects. The paddle mixer provides the torque necessary for demanding applications, where materials are more difficult to mix.

With its 15.47bar piston pump, the RMX-5000 produces up to 3.923m3/hour and can achieve vertical pumping distances up to 137.2m. Optional automatic lubrication greases wear components during operation. It also features a 454kg mixer capacity and a 544.3kg hopper capacity. The RMX-5000 is available with a

The RMX-5000 is designed for quick and simple clean-up with a hydraulic receiving hopper lift that provides easy access to the swing tube, which is designed for fast cleaning and maintenance while an optional hydraulic pressure washer can further ease clean-up. The RMX-5000 is customisable for a range of applications and is available in trailer- or skid-mounted versions. The machine is CE Certified, and meets